18

PREVENTIVE MAINTENANCE

Annually, inspect the apper in the 71SO to see that it is

open by looking down the drop tube opening (see in-

spection procedure below). Test the 71SO drop tube

seals with CARB procedure TP-201.1D. If the drop tube

seal passes testing, no further maintenance is required.

If the drop tube fails testing, replace the drop tube seal

with OPW P/N: H11931M for 4” Tubes. Re-test the 71SO

drop tube with CARB procedure TP-201.1D. The lower

tube o-ring seal OPW P/N: H14840M can also be re-

placed. If this does not correct the leak the 71SO needs

to be replaced.

FOR TESTABLE MODELS ONLY: The socket adaptor

can be removed and poppet and oat movement and

function inspected without removing the valve. See

Page 17 for full testing details. If replacement parts are

needed for testable models the following items are

available: OPW P/N 206741 Testable Inlet Tube S/A,

206740 Socket Adaptor and Cable Assembly, and 61SOK

-0001 Float Kit.

CAUTION: Do not insert any foreign object into drop

tube if apper is in the closed position. For exam-

ple, a tank level measuring stick. This will damage

the valve and void the Warranty. ALWAYS check

apper location before “sticking” the tank. If ap-

per is in the closed position, the tank is either over-

lled and you need to wait until the liquid level goes

down or the 71SO is damaged and needs to be re-

placed.

Inspection Procedure to Ensure Proper Operation

Note: For testable models valve does not need to be

removed from tank. See page 17 for testable instruc-

tions.

INSP 1. Remove the overll valve from the tank as de-

scribed in step 26.

INSP 2. Visually inspect the valve for damage. Make

sure no debris or foreign objects are in or on the valve.

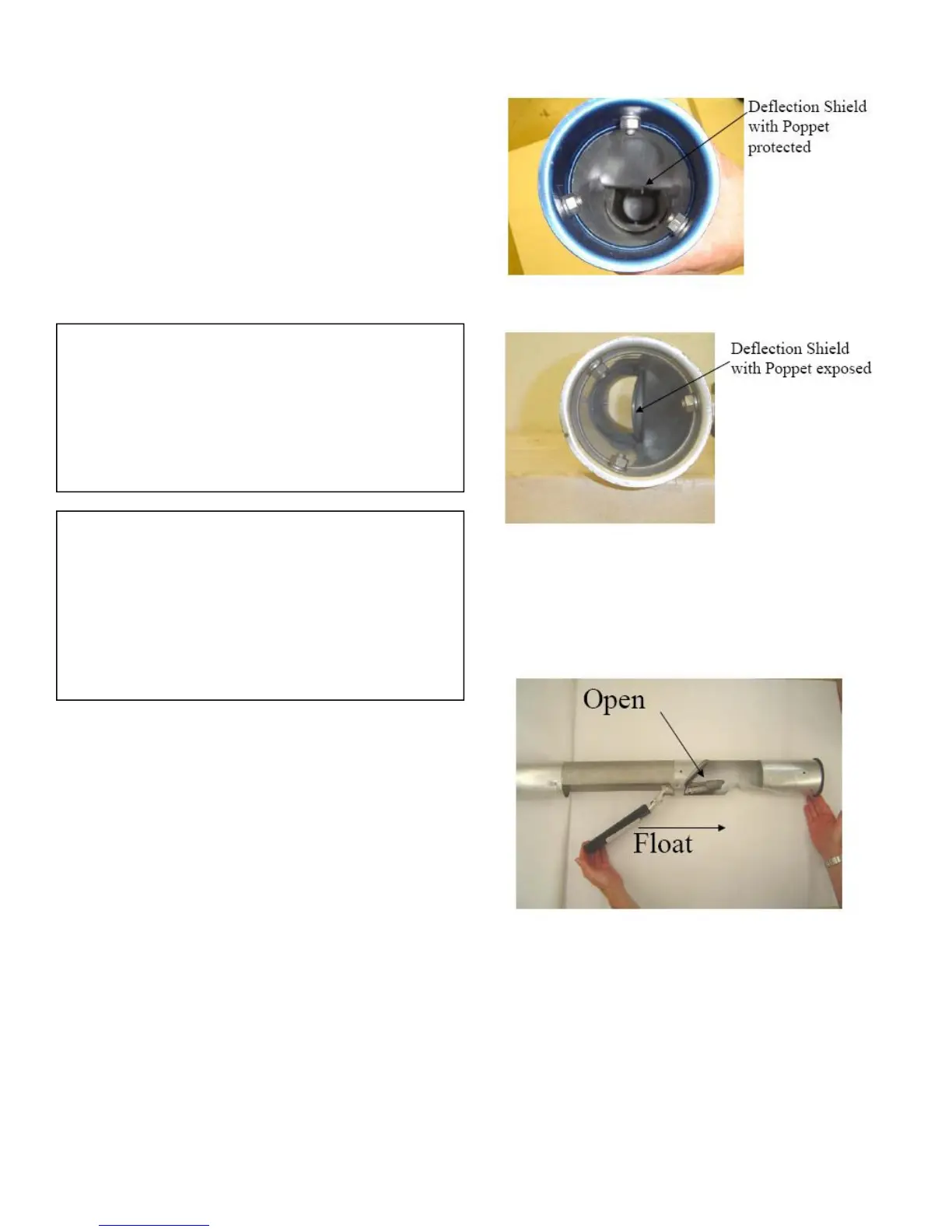

INSP 3. With the oat in the normal (down) position,

visually inspect the valve to ensure the poppet is not

exposed outside the deection shield. See Figure 27.

Good Valve

Bad Valve

Note: Figure 27 shows poppet location with oat arm

not activated.

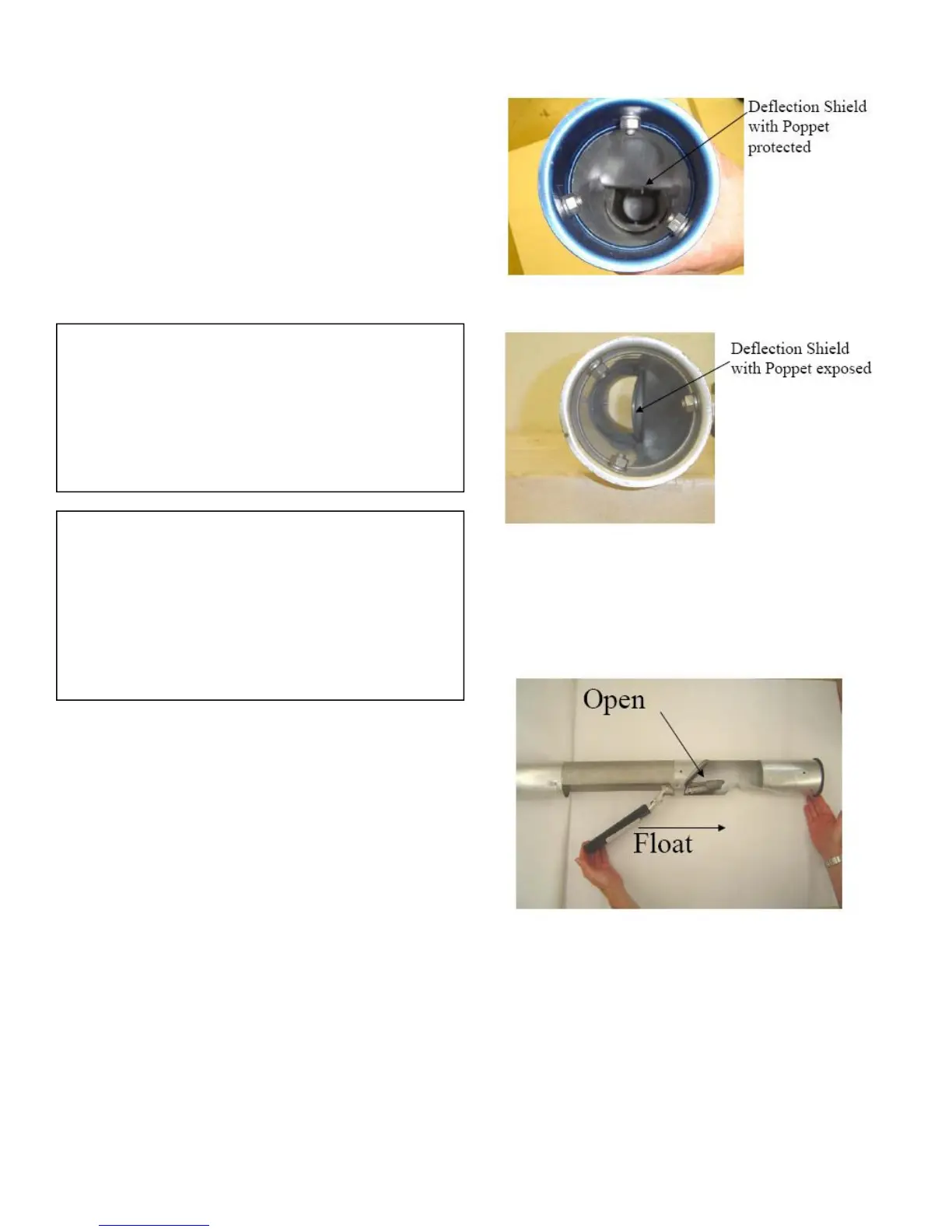

INSP 4. Inspect the oat by lifting upward. The oat

should move freely without any binding. See Figure

28.

INSP 5. View down the tube to ensure the poppet is

moving into the ow path when lifting the oat. See

Figure 29.

Figure 27

Figure 28

Loading...

Loading...