17

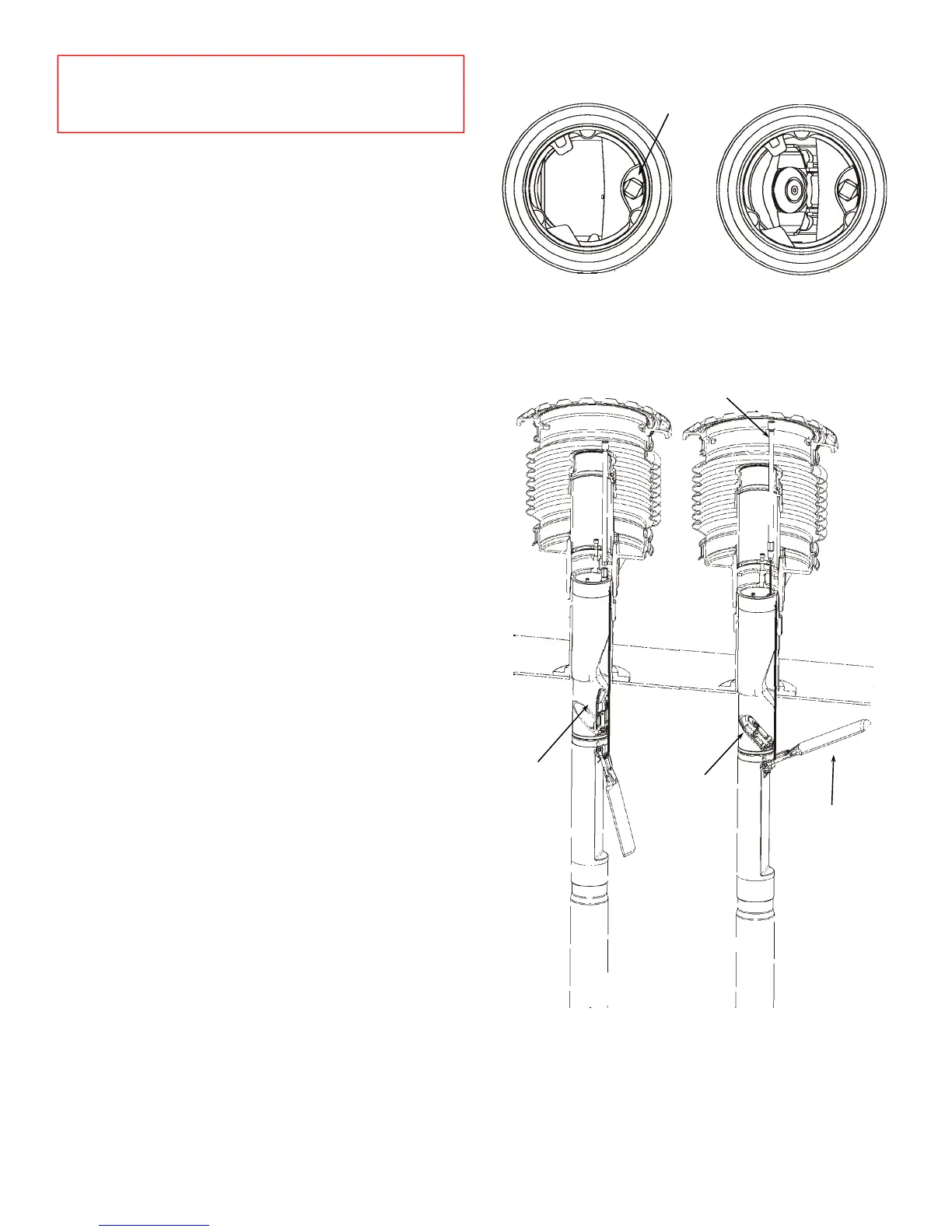

Pull on extension and

socket adaptor

TEST INSTRUCTIONS

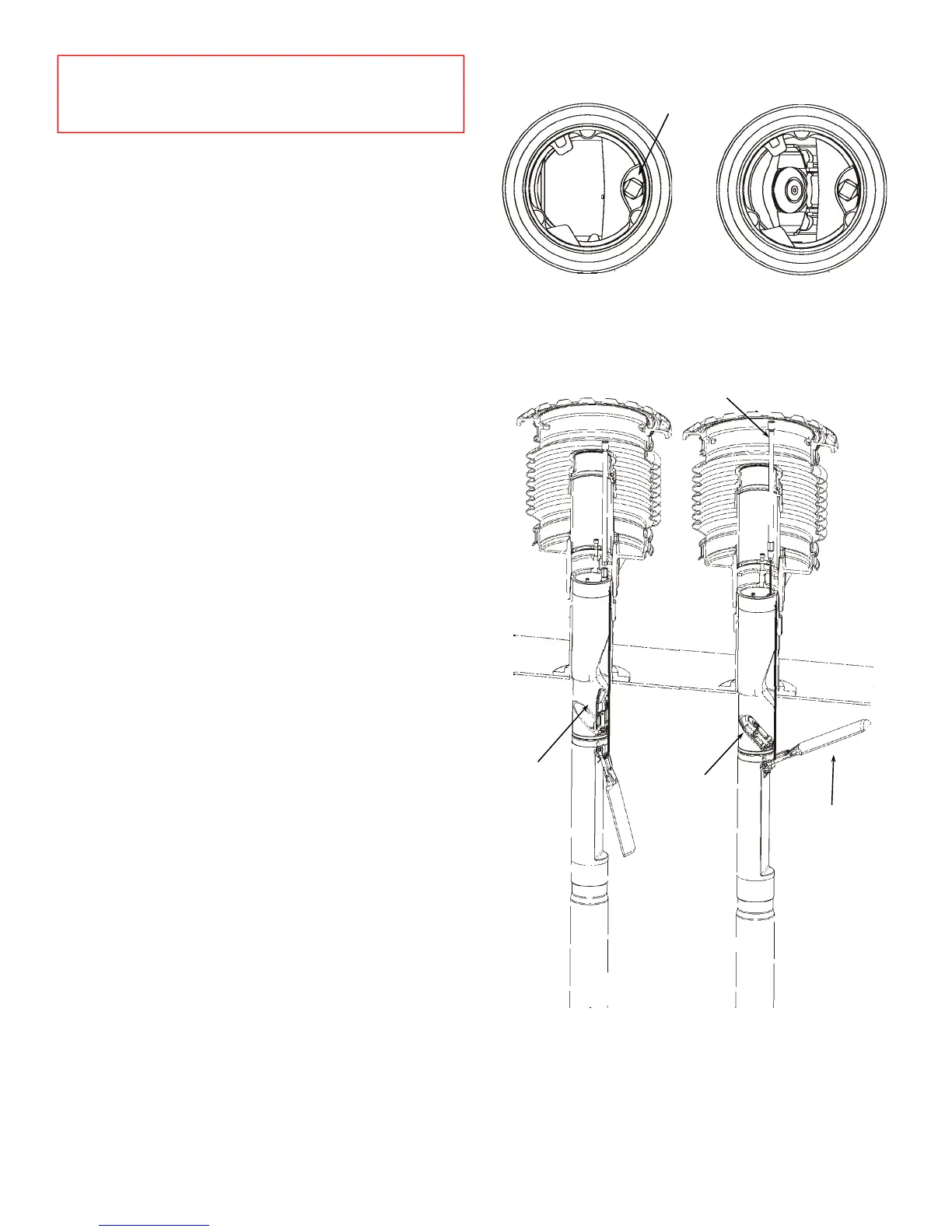

POPPET & FLOAT MOVEMENT

FOR TESTABLE MODELS ONLY

TOOLS NEEDED FOR TESTING:

1. 1/4” square drive extension or 3/8” square drive ex-

tension with 3/8” to 1/4” socket adapter.

2. Torque wrench / 1/4” or 3/8” square drive ratchet

wrench.

3. Pipe dope.

4. Flashlight (optional).

TEST STEP 1:

Remove spill container cover and ll cap from ll adapt-

er and look down into the tube and make sure no debris

or foreign objects are present. If debris or foreign ob-

jects are present take appropriate steps before proceed-

ing. Look down into the tube and ensure poppet is

completely protected by the deection shield. See Test

Figure 1. If poppet is exposed and tank is not full the

overll valve should be replaced. A ashlight may help

when inspecting the tube.

TEST STEP 2:

Unthread the socket adaptor assembly from the inlet

tube using a 1/4” square drive extension and wrench.

The extension will attach to the socket adaptor. Secure

all tools to ensure they don’t fall into the tank or valve.

With the extension still attached pull on the socket

adaptor and cable assembly and ensure oat and pop-

pet move / function properly. It should only require 3”

to 4” of movement and less than 5 lbs of force in order

to actuate the oat and poppet. When looking down

into the upper tube ensure poppet is visible and moves

into the ow path (see Test Figure 1 & 2) when socket

adaptor is pulled and resets properly when socket adap-

tor is released. If poppet does not actuate freely take

appropriate steps to correct.

TEST STEP 3:

Apply pipe dope to the socket adaptor threads. Pipe

dope should be a non-hardening gasoline resistant pipe

thread seal compound. Make sure poppet and oat

have reset properly and are not visible then install sock-

et adaptor and torque to 3.5 ft-lbs (42 in-lbs) minimum

to 5.0 ft-lbs (60 in-lbs) maximum. After installing socket

adaptor, to ensure vapor tightness, OPW recommends

conducting pressure testing per CARB TP201.1D. Some

areas may require pressure testing of overll valve per

CARB TP201.1D to ensure valve is vapor tight. If the

drop tube fails pressure testing it may be necessary to

check the seal at the poppet adaptor threads. Reinstall

ll cap and spill container cover after testing.

Open Poppet Closed Poppet

Socket

adaptor

Test Figure 1

Open

Poppet

Closed

Poppet

Float moves

up

Test Figure 2

Loading...

Loading...