Do you have a question about the OTTO MOTORS OTTO 100 V2.4 and is the answer not in the manual?

| Payload Capacity | 100 kg |

|---|---|

| Battery Life | 8 hours |

| Navigation | Autonomous with LiDAR and cameras |

| Connectivity | Wi-Fi, Ethernet |

| Charging Time | 2 hours |

| Communication | Wi-Fi, Ethernet |

| Operating Temperature | 0°C to 40°C |

| IP Rating | IP54 |

| Max Speed | 2.0 m/s |

| Maximum Speed | 2.0 m/s |

Illustrates DANGER, WARNING, and CAUTION callout types.

Explains various hazard labels used on OTTO Motors products.

Outlines key safety topics for personnel working with AMRs.

Discusses requirements for facility floors and environments for safe AMR operation.

Specifies maximum payload limits for the OTTO 100 AMR.

Provides precautions for handling lithium technology battery packs safely.

Explains how AMRs detect obstacles and the use of perception-assist flaps.

States terms and conditions regarding the manual's information and product use.

Key instructions and safety considerations before using the product.

Best practices to ensure protection of life and equipment around the AMR.

Identifies potential risks and hazards associated with normal AMR operation.

Specifies human exclusion zones and safe operating distances for AMRs.

Details the AMR's safety systems, including LiDAR scanners and sensors.

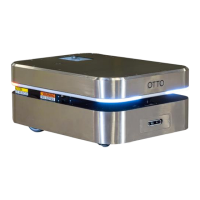

Presents key technical specifications of the OTTO 100 V2.4 AMR.

Describes the internal lift mechanism and its positions.

Details the location and function of various buttons and connection ports on the AMR.

Explains how light pipes and visual indicators signal the robot's operational state.

Covers LiDAR, 3D cameras, and rear sensors for obstacle detection and navigation.

Explains how to use circuit breakers and the LOTO procedure for power disconnection.

Information on autonomous charging using OTTO 100 Charger/Fast Charger docks.

Details on the Staging Cart's design, payload capacity, and braking mechanism.

Instructions on how to access the AMR's attachment interface port.

Details on available ports like Ethernet, USB, and CPC connectors.

Describes the camera's field of view and its role in obstacle detection.

Information on ongoing testing and updates for the 3D Perception Attachment.

Summarizes observations on object detection distances and factors affecting them.

Lists common sources of false positive object detection for the AMR.

Presents test outcomes for obstacle detection and collision avoidance scenarios.

Estimated time needed for the unboxing process.

Lists necessary tools and materials for unboxing the AMR.

Lists the components included in the AMR packaging.

Guidance on checking specific items during the unboxing process.

Step-by-step instructions for safely unboxing the OTTO 100 AMR.

Procedure for safely deactivating the AMR for maintenance.

Step-by-step guide for powering on and starting the OTTO 100 V2.4 AMR.

Instructions for safely powering off and shutting down the OTTO 100 V2.4 AMR.

Procedures for charging the OTTO 100 V2.4 AMR using different charger types.

Safe methods for manually moving an unpowered or disabled AMR.

Guidelines and precautions for lifting and moving the OTTO 100 V2.4 AMR.

Recommendations for storing the AMR for extended periods.

Specifics for storing the AMR and its batteries for long durations.

Overview of the OTTO App's functions for single-robot control and fleet management.

Instructions for operating the AMR using the OTTO App in manual mode.

Procedures for sending the AMR to a destination using the OTTO App.

How to navigate the AMR to specific points (markers) in the facility map.

Instructions for sending the AMR to pre-configured waypoints or routes.

Initial steps for connecting the AMR to a computer via Ethernet.

Guide to configuring computer network settings for AMR connection.

Steps to configure network settings on Windows 7 for AMR connection.

Procedure to verify network connectivity by pinging the AMR.

Steps to connect the AMR to a network for autonomous operation.

Daily visual inspection to ensure no damage has occurred since the last operation.

Procedure for cleaning the LiDAR lens for optimal performance.

Procedure to balance battery cells and the Battery Management Unit for optimal health.

Inspection of wheels and castors for wear, damage, and proper function.

Procedure to assess the battery's health and expected lifespan.

Guidelines for the proper disposal of end-of-life batteries.

FCC compliance information and declarations for the device.