- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

NANO 2000T Polisher

4.5 Selected Polishing Procedures

4.5.1 1095 Carbon Steel (Pearlite and Martensite Phases) Preparation of high carbon steels is

fairly straight-forward. Depending upon the heat treatment, the grinding and polishing times may

increase for the harder martensite phase.

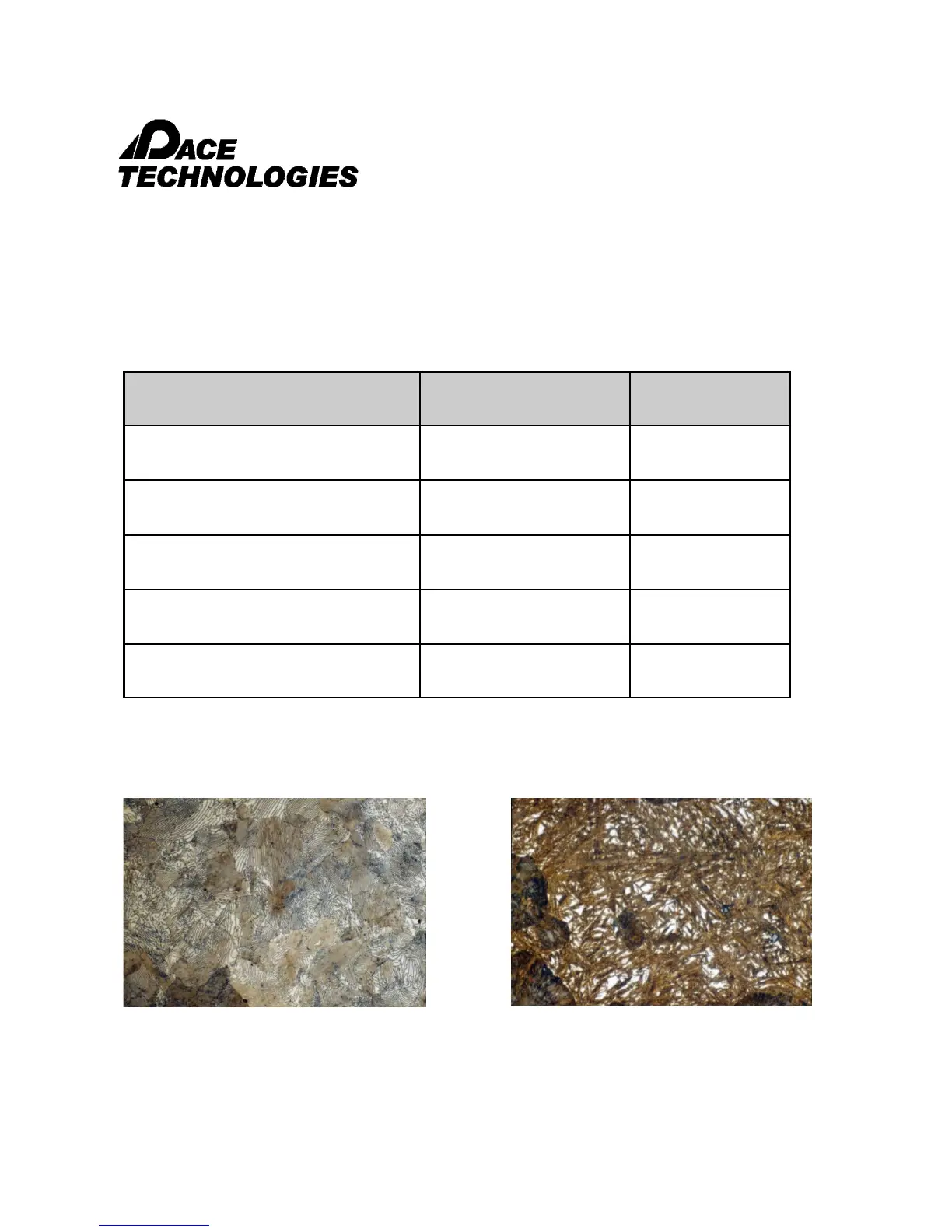

1095 Steel, Furnace-Cooled, etched with

2% nital, 400X B.F.

Microstructure: Pearlite structure

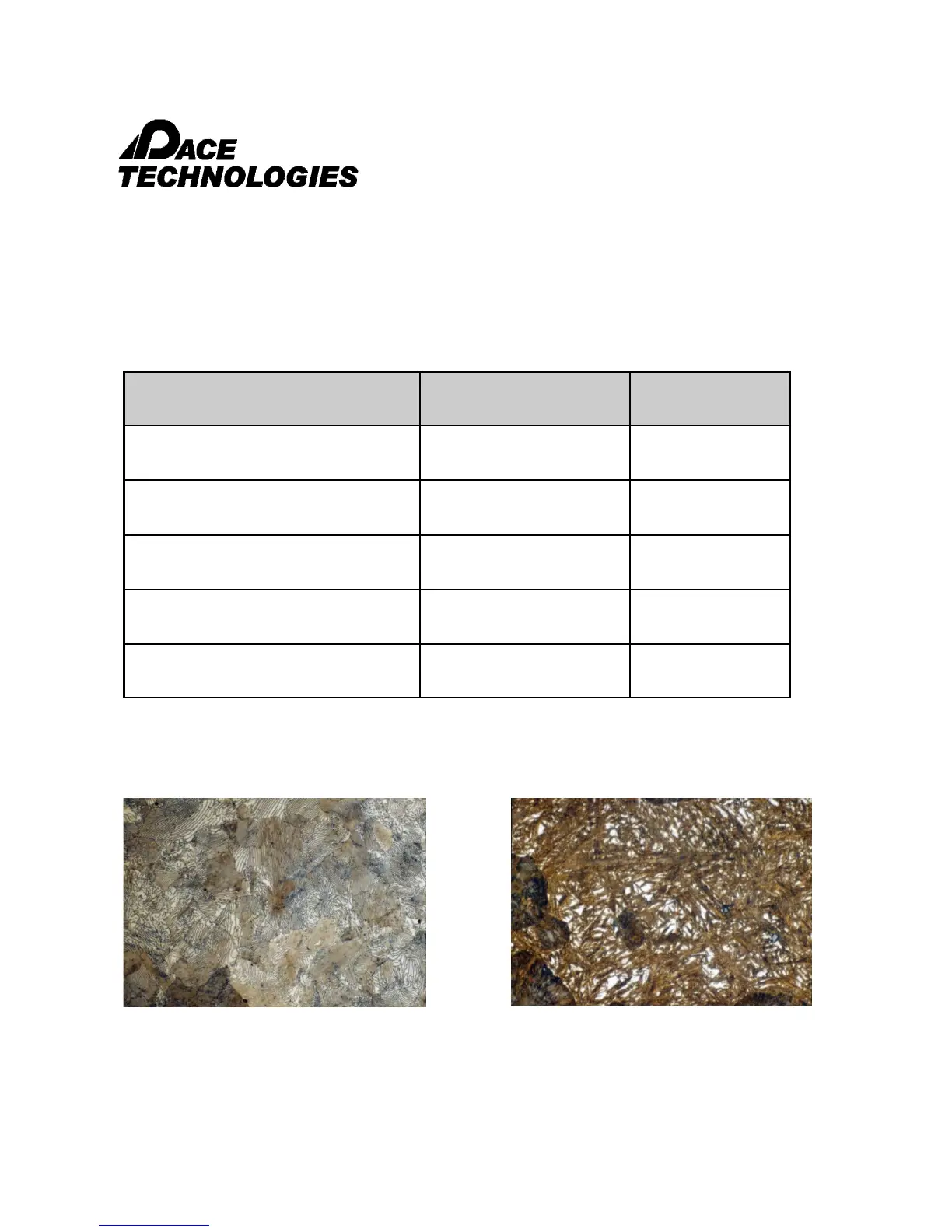

1095 Steel, Water-Quenched, etched with

picric acid, 1000X B.F.

Miicrostructure: Martensite structure

14

Abrasive/surface Lubricant Time

PDGD-125M Diamond Grinding Disk water Until plane

SIRIUS Composite grinding disk 9 um DIAMAT Diamond 3 minutes

ORION Composite grinding disk 3 um DIAMAT diamond 3 minutes

1 um DIAMAT diamond on ATLANTIS pad DIALUBE Extender 2 minutes

0.05 um Nanometer alumina on MICROPAD

or TRICOTE pad

1 minute

Loading...

Loading...