Health risk due to aerosols

Aerosols might be dangerous to your health. That’s why they ought not to

be inhaled. It might also be necessary to wear protective clothes. Please

pay attention to the corresponding standards and safety rules.

► Aerosol generation is started by setting the pre-pressure at the pressure

control valve. The pressure gauge serves as control unit for the operation

level.

After long periods of inactivity or after having refilled the reservoir, the liquid

inlet tube may contain air bubbles. It may take some time until the generator

produces a steady output.

Nozzle pre-pressure

1. At first we suggest to set the nozzle pre-pressure to about 3.0 bar.

2. As soon as a homogenous aerosol cloud is visible at the tube outlet (dark

background makes the cloud best visible) the nozzle pre-pressure can be

set to the desired values.

3. To ensure steady generation the pre-pressure should be set to a minimum

value of 0.7 bar.

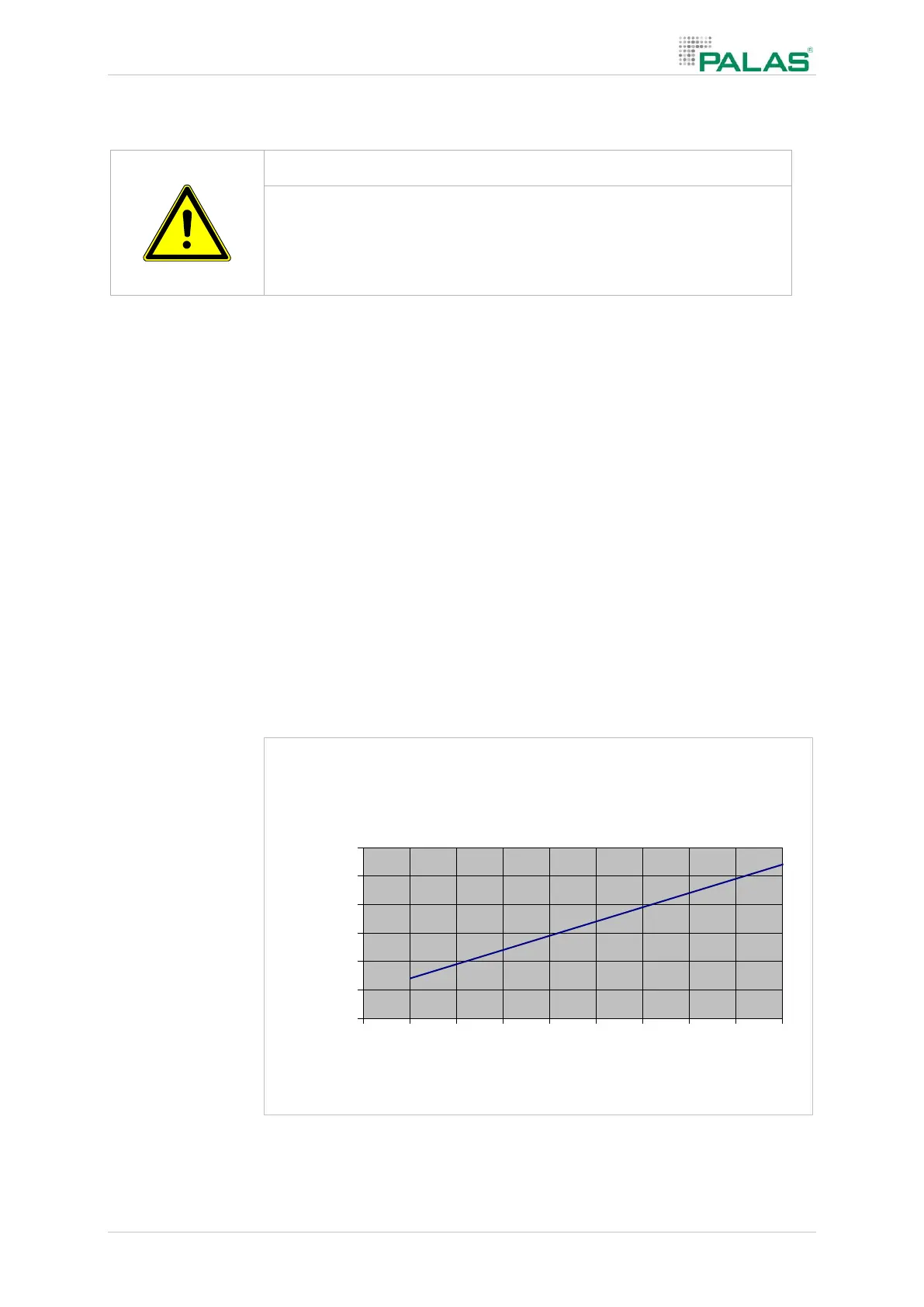

The nozzle pre-pressure influences the generated volume flow as well as the

particle production rate (and thereby the produced mass flow). If KCl solutions

are used, the mass flow is also influenced by the KCl concentration. The

following figure shows the volume flow as a function of the nozzle pre-pressure.

Relation between pre-pressure and volume flow AGK 2000

0

2

4

6

8

10

12

0 0,5 1 1,5 2 2,5 3 3,5 4 4,5

Volume flow in l/min

pre-pressure in bar

Relation between pre-pressure and volume flow

AGK-2000

Loading...

Loading...