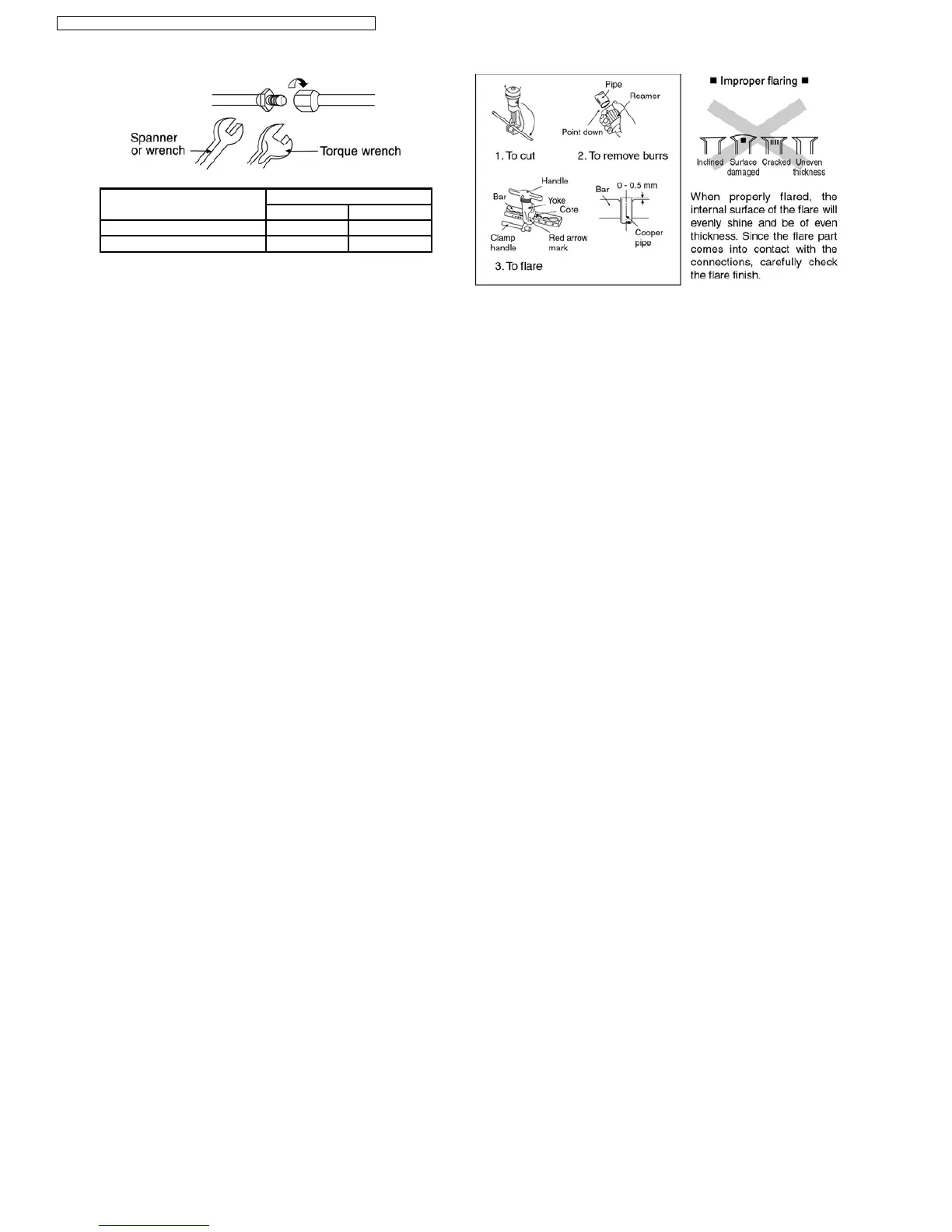

MODEL Piping size (Torque)

Gas Liquid

C7DK, C9DK, A7DK, A9DK 3/8” (42 N.m) 1/4” (18 N.m)

C12DK, A12DK 1/2” (55 N.m) 1/4” (18 N.m)

Connecting The Piping To Outdoor Unit

Decide piping length and then cut by using pipe cutter. Remove

burrs from cut edge. Make flare after inserting the flare nut

(located at valve) onto the copper pipe.

Align center of piping to valves and then tighten with torque

wrench to the specified torque as stated in the table.

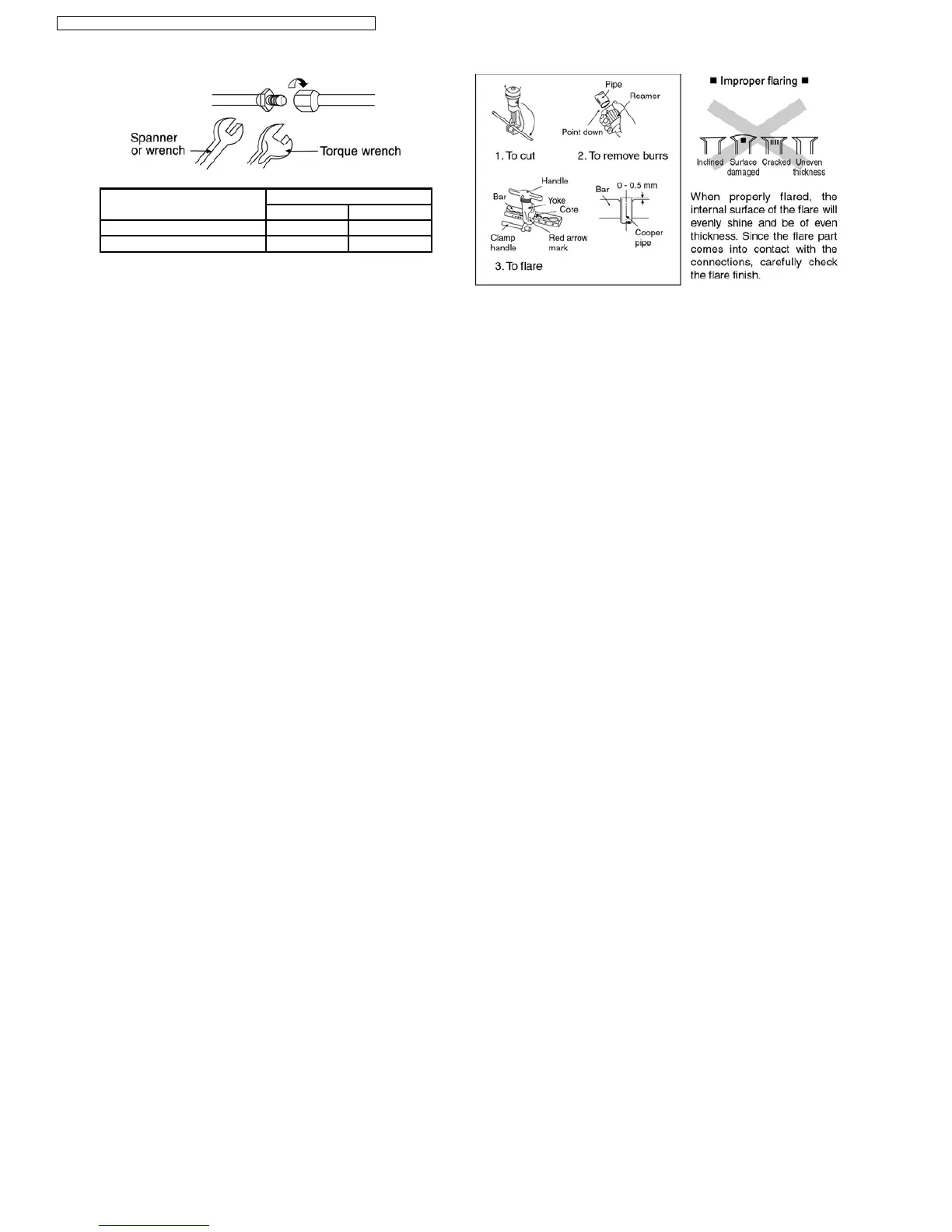

CUTTING AND FLARING THE PIPING

1. Please cut using pipe cutter and then remove the burrs.

2. Remove the burrs by using reamer. If burrs is not

removed, gas leakage may be caused.

Turn the piping end down to avoid the metal powder

entering the pipe.

3. Please make flare after inserting the flare nut onto the

copper pipes.

52

CS-A7DKD CU-A7DKD / CS-A9DKD CU-A9DKD / CS-A12DKD CU-A12DKD /

Loading...

Loading...