45

2. Installation work

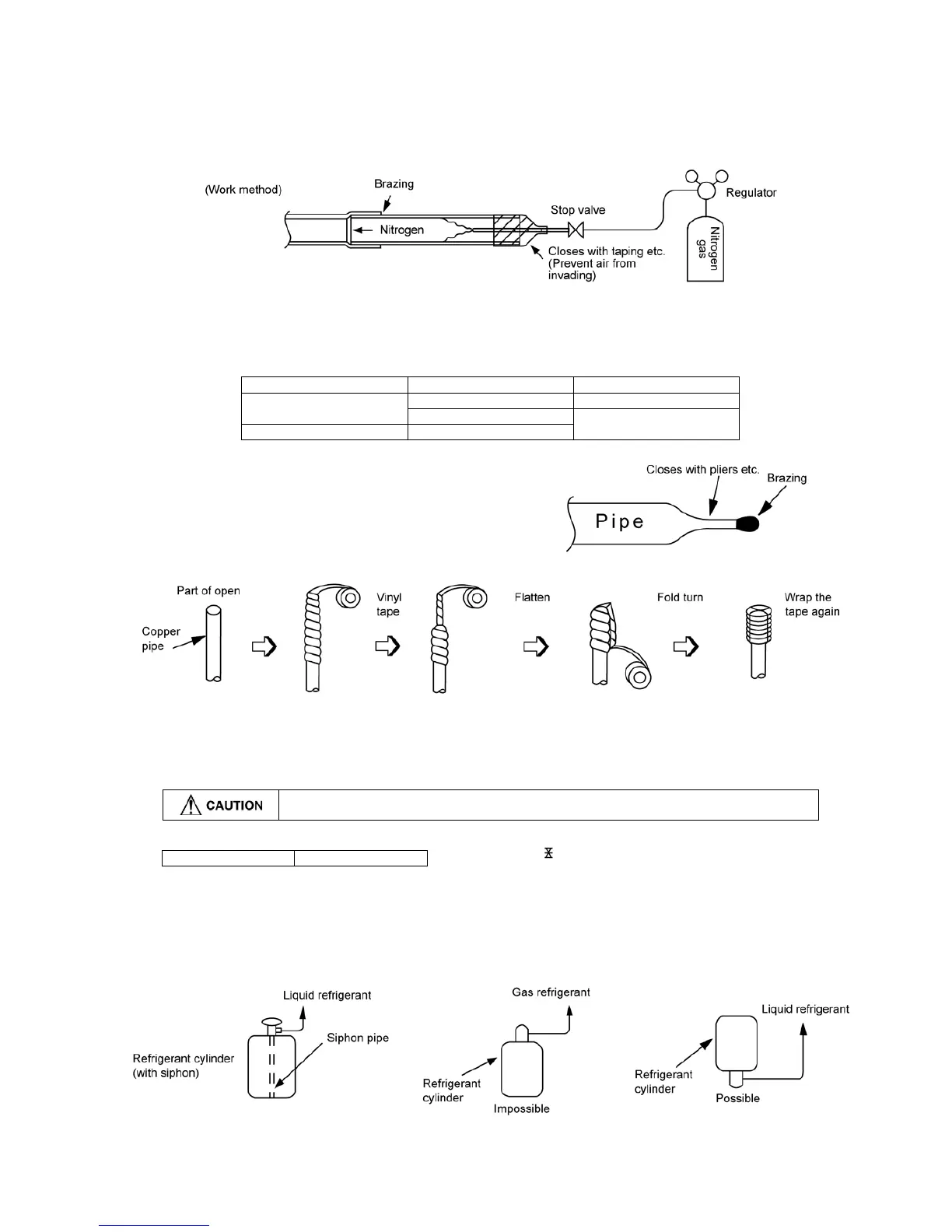

a. Brazing work

Brazing work needs replacing air inside pipe with nitrogen gas in order to prevent oxidization scale from occurring. This is

called nitrogen replacement, and one of very important work in brazing refrigerant piping. (Oxidation preventive is not

possible to use)

b. Prevention measure for refrigerant piping

Prevention measure for refrigerant piping is very important work to prevent water-dust-rubbish from getting in.

All piping terminals needs sealing such as shown below.

• How to pinch

Close terminal part of piping with pliers and seal the

gap with brazing.

• How to tape

Seal terminal part of piping with vinyl tape.

3. Vacuum pumping

The purpose of vacuum pumping work is to remove and dry air inside the piping or nitrogen at air tightness test.

Perform the work carefully.

Vacuum pump capacity 60 l/min or more

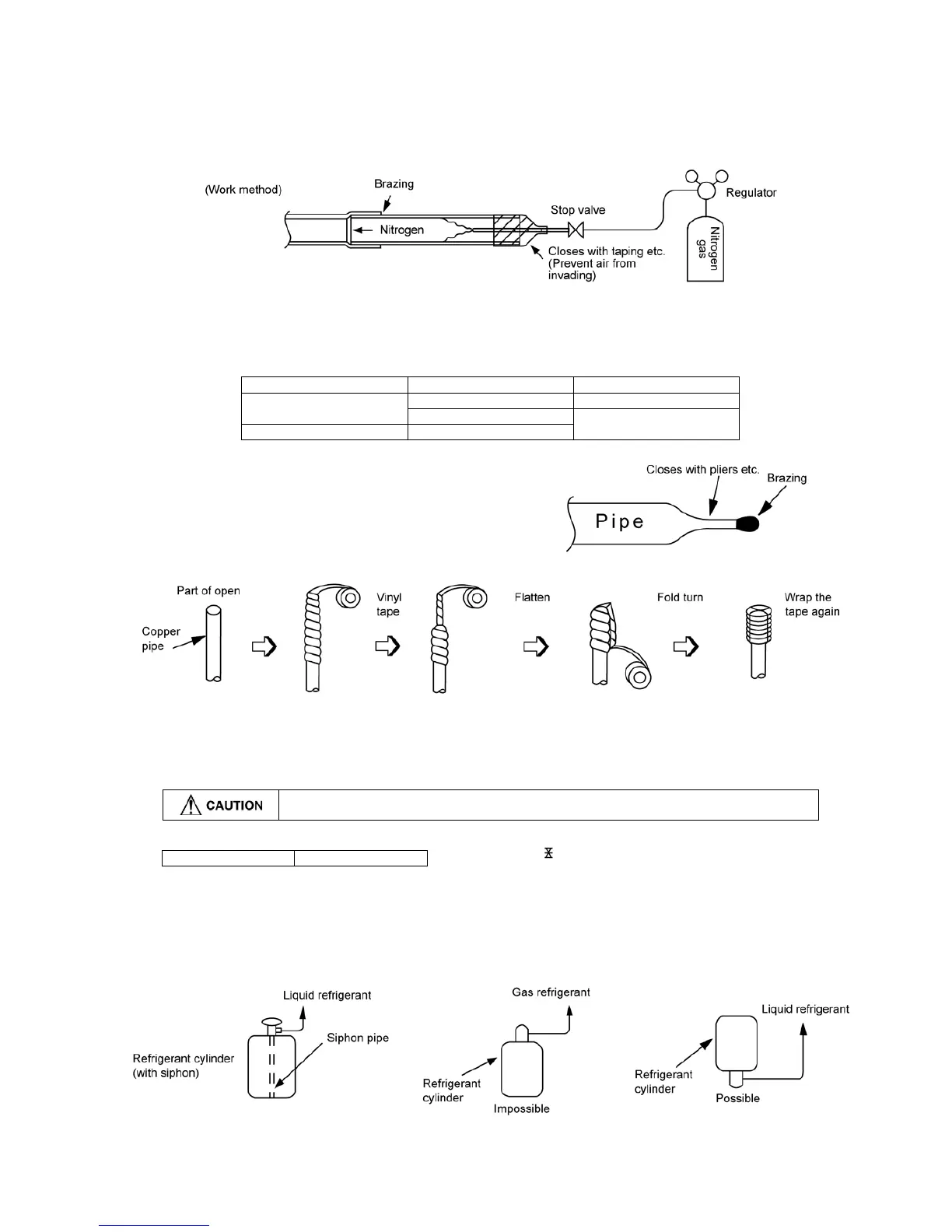

4. Refrigerant filling

Refrigerant filling must be done in the state of liquid

refrigerant.

If this is done in gas refrigerant, the balance of refrigerant

composition will collapse and damage the operation.

For the use of a gas cylinder without siphon inside, turn it

upside down and use it.

(We recommend manifold with sight glass.)

Place Period of work Method of seal

Outside More than 1 month Pinch

Less than 1 month Pinch or taping

Inside Not specified

Use the vacuum pump with the backflow prevention mechanism to prevent backflow of oil.

Vacuuming time 60 minutes or more

Loading...

Loading...