Slide # 23

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

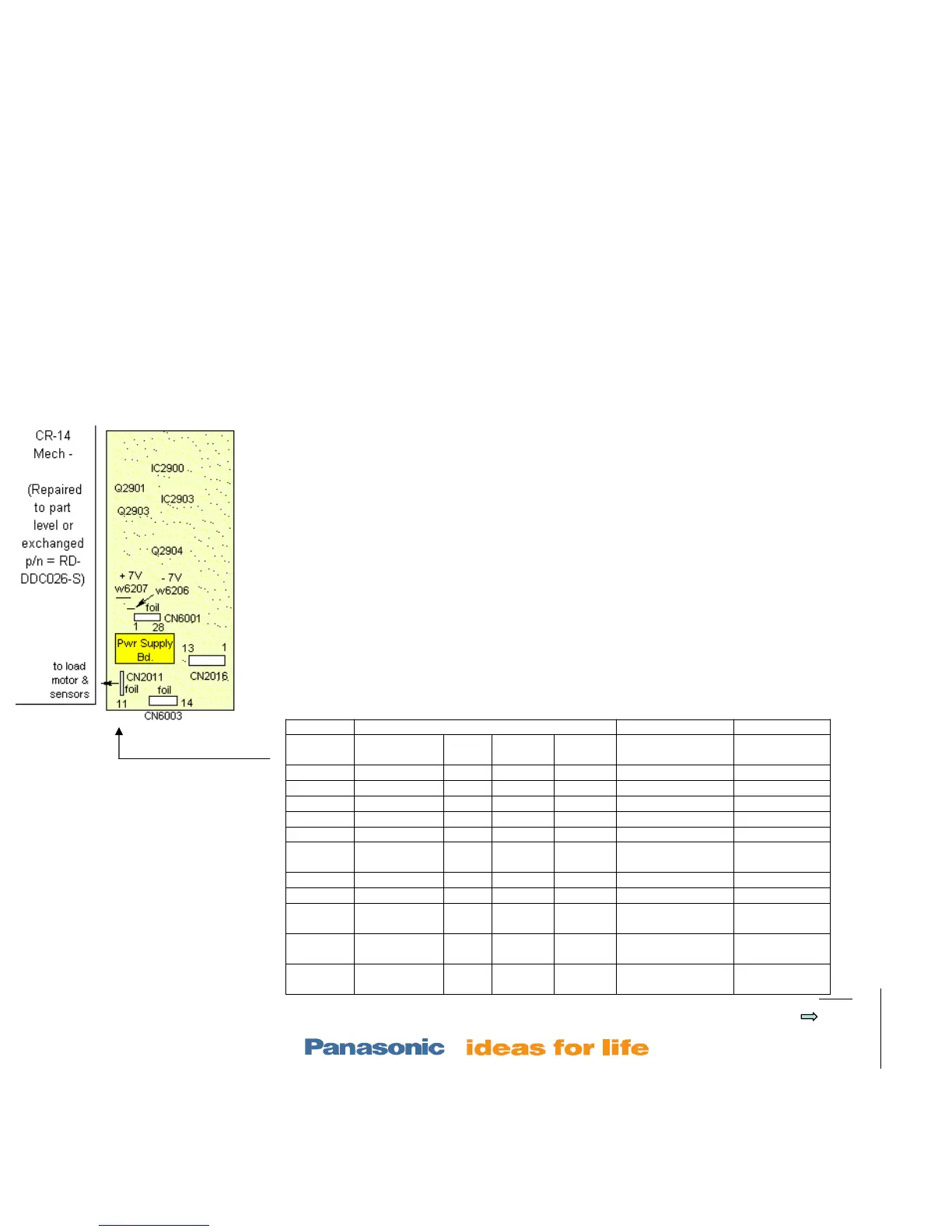

Mech Troubleshooting. Is it the Mech or the Circuitry?

When the mechanism does not work correctly, is the problem mechanical? Is it

a sensor under the mech? Is it on the main board by the microprocessor?

Isolation Procedure:

1. Note which tray is in the laser assembly. Unplug the ribbon cable at CN2011.

2. Compare the dc voltages at the 11 pin connector (without the cable inserted) to the

“No cable” column voltages shown below. If any are different, the main board is at fault.

Check the pull up resistors and check the main board for cracks.

3. Note the position of the trays in the mechanism. Reconnect CN2011.

4. Compare the dc voltages at the same CN2011 connector to the corresponding

column in the chart below (cable inserted). Pictures are on the previous page.

If any of the voltages do not agree with the chart below, the corresponding sensor (Q1-5, Sw3,4) is

bad. If the voltages all agree, the mechanical assembly is defective or out of alignment. Replace

the assembly, or do the prev. transfer alignment.

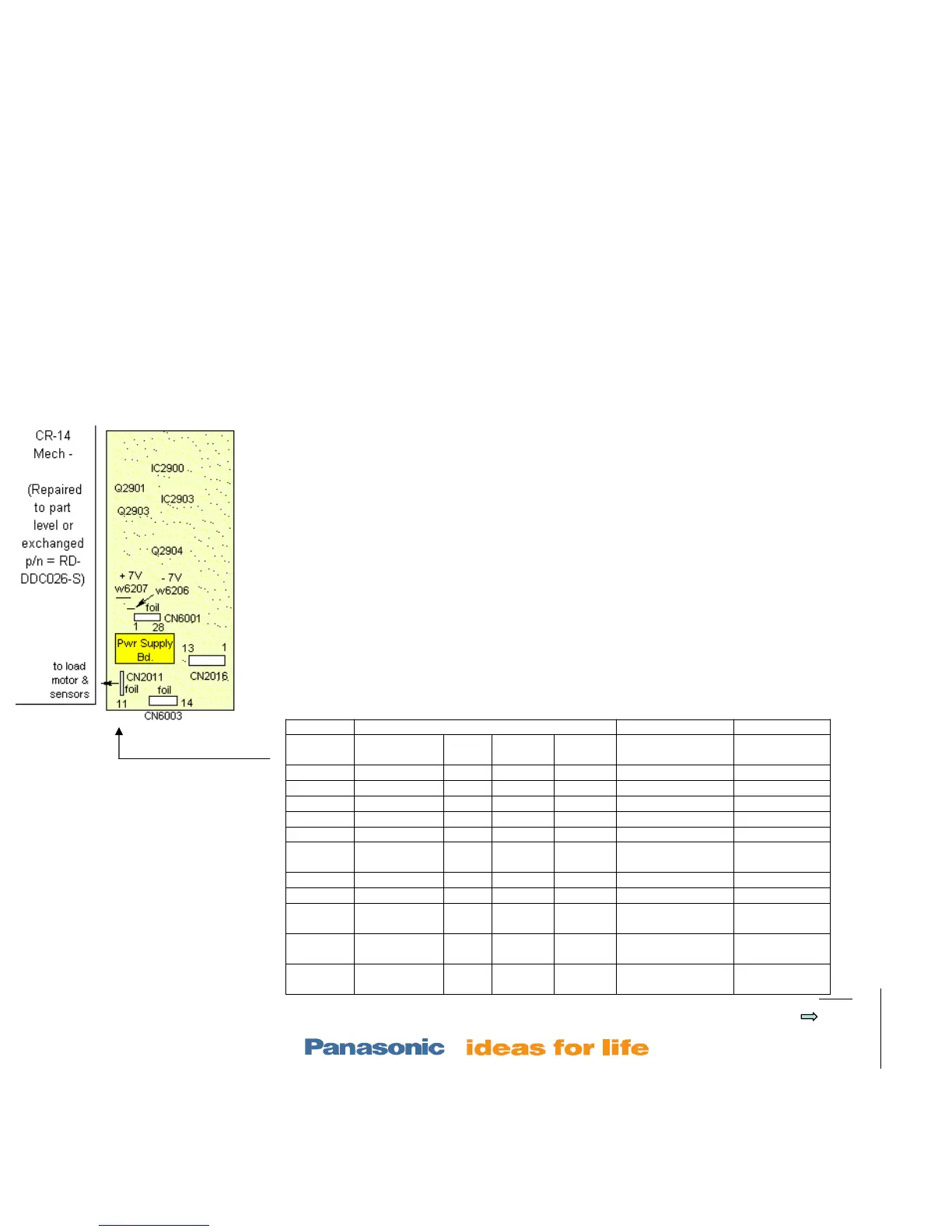

CN2011 Connector Voltage

CN2011/

pin

No CN2011

cable

Tray

1 in

Trays

2-5 in

All trays

out

CN2011/pin

corresponds to:

Changes

during

1 8.2V 7.5V 7.5Vdc 7.5Vdc Motor driver Vcc

2 gnd No change

3 5Vdc 5Vdc 5Vdc 5Vdc Q4 Mode sensor Elevator dwn

4 gnd

5 5Vdc 0Vdc 5Vdc 0Vdc SW3 Top sw

6 5Vdc 0Vdc 0Vdc 0Vdc Q1 UD (lever

sensor)

Trays

stocked

7 0Vdc 0Vdc 0Vdc 0Vdc Motor fwd

8 0Vdc 0Vdc 0Vdc 0Vdc Motor rev

9 5Vdc 0Vdc 0Vdc 0Vdc Q2 close (gear

sens)

10 5Vdc 0Vdc 0Vdc 5Vdc Q3 home (gear

sens)

Tray moves

back / forth

11 5Vdc 0Vdc 0Vdc 0Vdc Q5 open (lever

sens)

H at tray out

Loading...

Loading...