6

PSFS 250 A1

GB

CY

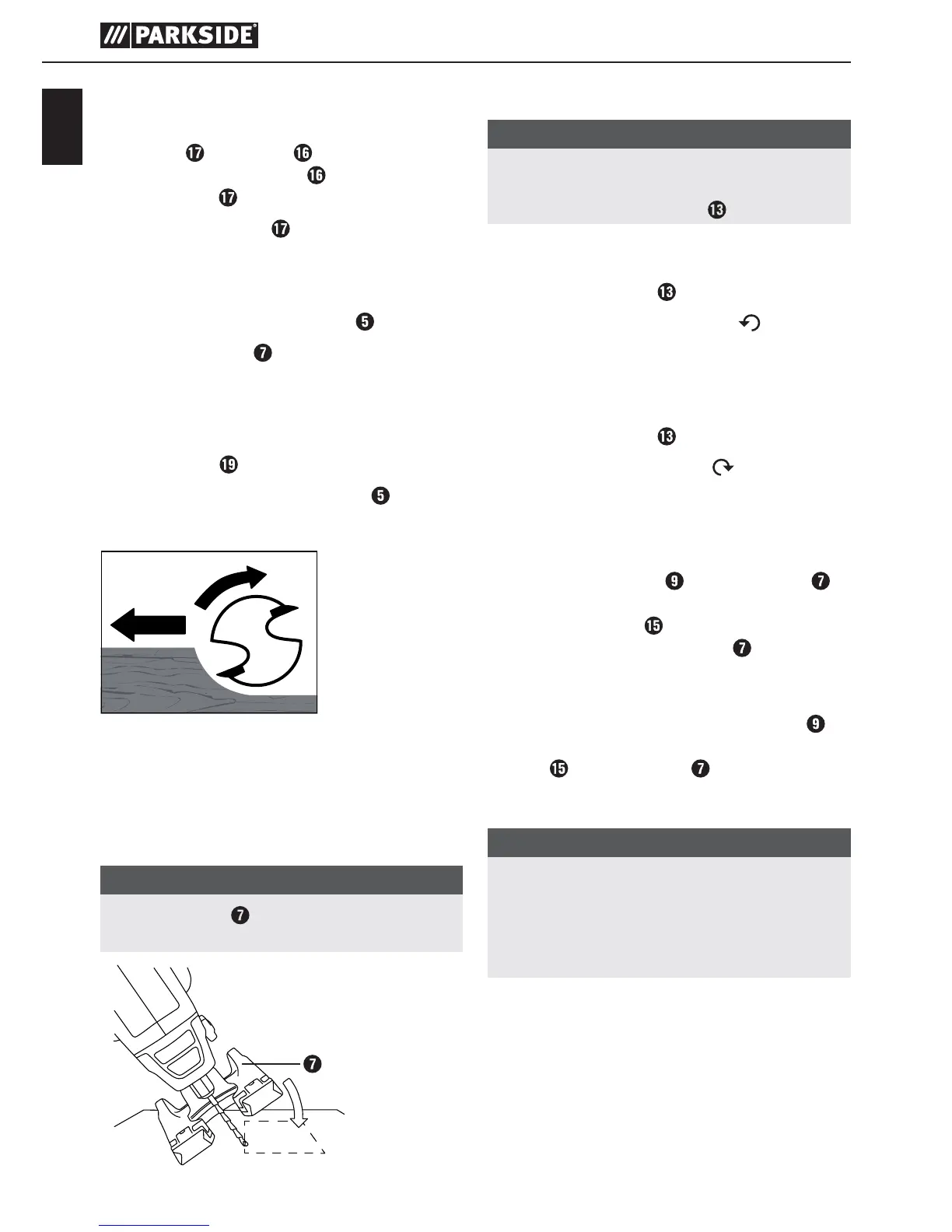

Fitting abrasive belts

♦ Push the abrasive belt onto the abrasive belt

mandrel

from above . Tighten the bolt on

the abrasive belt mandrel in order to fix the

abrasive belt .

♦ Fit the abrasive belts

as described in the

section "Replacing tools".

Adjusting the working depth

♦ Loosen the wing adjusting screw .

♦ Push the footplate

down to the required

working depth (around 3.2 mm more than the

material thickness for complete cutting). The

maximum recommended cut depth forward is

13 mm *(applies only to multipurpose milling

cutters (HSS) ).

♦ Retighten the wing adjusting screw

.

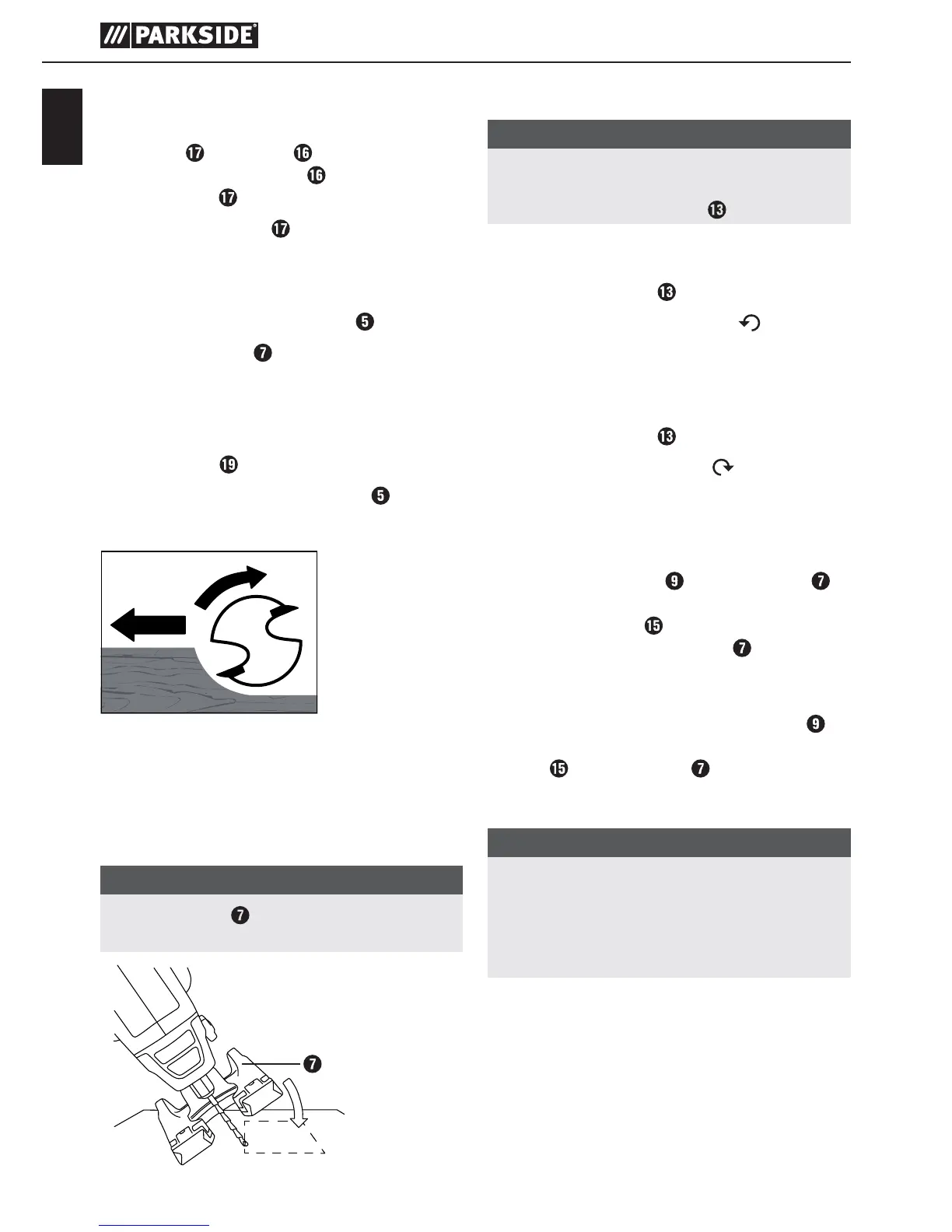

Milling direction on edges

Carrying out plunge cuts

♦ Introduce the bit into the workpiece at an angle

of 45°.

♦ Slowly change the angle of the bit to 90°

before starting the cut.

NOTE

► The baseplate

must be flush with the material

surface.

Swivelling the handle

NOTE

► Do not rotate the handle while working.

Remove the plug from the mains socket and

ensure that the swivel lock

is engaged.

Swivelling to the horizontal position:

♦ Press the swivel lock

and hold it down.

♦ Rotate the handle anticlockwise

from the

vertical to the horizontal position until the swivel

lock engages.

Swivelling to the vertical position:

♦ Press the swivel lock

and hold it down.

♦ Rotate the handle clockwise

from the hori-

zontal to the vertical position until the swivel

lock engages.

Using the parallel guide

♦ Undo the wing screw on the baseplate ,

and push the guide rod on the circular/parallel

cutting attachment through the two recesses

on the bottom of the baseplate so that the

parallel guide is facing downwards.

♦ Align the tool at the required distance from the

workpiece edge. Tighten the wing screws

in

order to fix the circular/parallel cutting attach-

ment to the baseplate .

Sawing circles

NOTE

► Depending on the required results, the guide

hole is placed either on the inside or the out-

side of the circle circumference. Inside for

a hole – outside for a disc. The radius can

be fixed approximately between 5 to 16 cm.

♦ Draw a circle on the workpiece.

♦ Mark the centre of the circle and drill a hole in

it (plunge cut).

♦ Drill a guide hole on the outside of the circle

(plunge cut) (guide hole diameter 3 mm).

Loading...

Loading...