Maintenance Instructions

MODEL: P-1/2-HP, P-3/4-HP, P-1, P-1 1/2, P-2

NOTE:

This manual covers several different configurations of P-Series pumps.

Be sure to select the appropriate model number for your pump.

DISASSEMBLY

1. Remove the four (4) snap ring screws. Now the snap ring can

be removed using a screwdriver or a pair of pliers.

2. Insert a 2 inch threaded pipe through the center hole at the end

of the housing to remove the head. Pull with a rocking motion to

remove. Head O-rings can easily be replaced.

3. Unscrew the fan cover screws and remove the fan cover and

drip shield. Place the screwdriver between fan blades and

unscrew the impeller nut using a

3

/4 inch open wrench in a

counterclockwise rotation. Impeller nut O-ring can be replaced.

4. With the pump in a vertical position, impeller up, place a screw-

driver through the discharge port wedging between the impeller

top and the housing. Carefully lift the impeller and remove. If

impeller does not remove easily, proceed to step 5.

5. Remove the four (4) motor bolts located beneath the motor

bracket. Motor and housing are now separated. Do not try to

remove shaft as this is an integral piece with the motor rotor.

Slinger and lip seal can be replaced. Using a rubber mallet hit

the pump bracket lightly, top side facing motor, until the impeller

and keyway pop loose.

ASSEMBLY

1. With the motor in a vertical position, shaft upwards, place hous-

ing over shaft, lining up motor bolt holes in the mounting bracket

with holes in the motor. Be sure the slinger is properly in place.

Screw the motor bolts into the holes beneath the mounting

bracket in a diagonal sequence.

Be sure motor screws are tight.

2. Insert the impeller into the housing until it bottoms out. Do not

hammer the impeller and sleeve down on the shaft. Line up the

keyway and insert key by lightly tapping it with a hammer. Screw

the impeller nut clockwise holding impeller. Be sure impeller nut

O-ring is properly in place. After handtight, turn with wrench 180

degrees,10-15 inch lbs. DO NOT OVERTIGHTEN.

3. Replace the fan cover and drip shield. Insert the fan cover

screws and tighten. Be sure fan is not rubbing against fan cover.

4. Place the pump upright resting on the motor. Look down into the

housing and, while rotating the impeller, check to see that the

impeller is centered. The impeller must not be touching the side

of the housing.

5. Wet head and head O-rings. Be sure head O-rings are properly

in place. Insert 2 inch threaded pipe into the head and replace

in housing. The threaded pipe should be tapped with a mallet,

pushing the head into the housing until the snap ring groove is

exposed. Remove pipe and replace snap ring. Line up through

holes in snap ring

with the threaded

holes in the

head by rotating

the snap ring

counterclockwise.

Insert and tighten

the four (4) snap

ring screws.

DISASSEMBLY

1. Remove the four (4) snap ring screws, being careful not to lose

the O-rings. Remove the snap ring using a screw driver or a

pair of pliers.

2. Insert the appropriate threaded pipe through the center hole

at the end of the housing to remove the head. Pull with a rock

ing motion to remove. Head O-ring can easily be replaced.

3. Take the plug out from the back of the fan cover or drip shield.

Remove impeller nut assembly using a 7/16” wrench. Insert a

screw driver in the slot of the motor shaft and unscrew the

impeller counterclockwise using ngers or the handle end of a

pair of pliers.

4. Remove the four (4) motor bolts located beneath the motor

bracket. Motor and housing are now separated. Do not try to

remove the shaft as this is an integral piece with the motor ro

tor. Slinger and lip seal can be replaced.

ASSEMBLY

1. With the motor in a vertical position, shaft upwards, place

housing over the shaft, lining up motor bolt holes in the

mounting bracket with holes in the motor. Be sure the slinger

is properly in place. Conduit box should be 180˚ from the

outlet. Screw the motor bolts into the holes beneath the

mounting bracket in a diagonal sequence. Be sure motor

screws are tight.

2. Insert the impeller into the housing. With one hand holding

a screwdriver in the slot of the motor shaft and the other hand

on the impeller, turn the impeller clockwise with ngers or the

hankle end of a pair of pliers until the impeller bottoms out.

3. Attach impeller nut assembly to shaft with impeller nut O-ring

using a 7/16” wrench.

4. Place the pump upright resting on the motor. Look down

into the housing and while rotating the impeller, check to

see that the impeller is centered.

The impeller must not be touching the side of the housing.

5. Replace plug in the back of the fan cover or drip shield. Wet

head and head O-ring. Be sure head O-ring is properly in

place. Insert the appropriate threaded pipe into head and

replace in housing. The threaded pipe should be tapped with

a mallet, pushing the head into the housing until the snap

ring grove is exposed. Remove pipe and replace snap

ring. Line up through holes in the snap ring with the threaded

holes in the head by rotating the snap rings counter cloclwise.

Insert and tighten the four (4) snap ring screws.

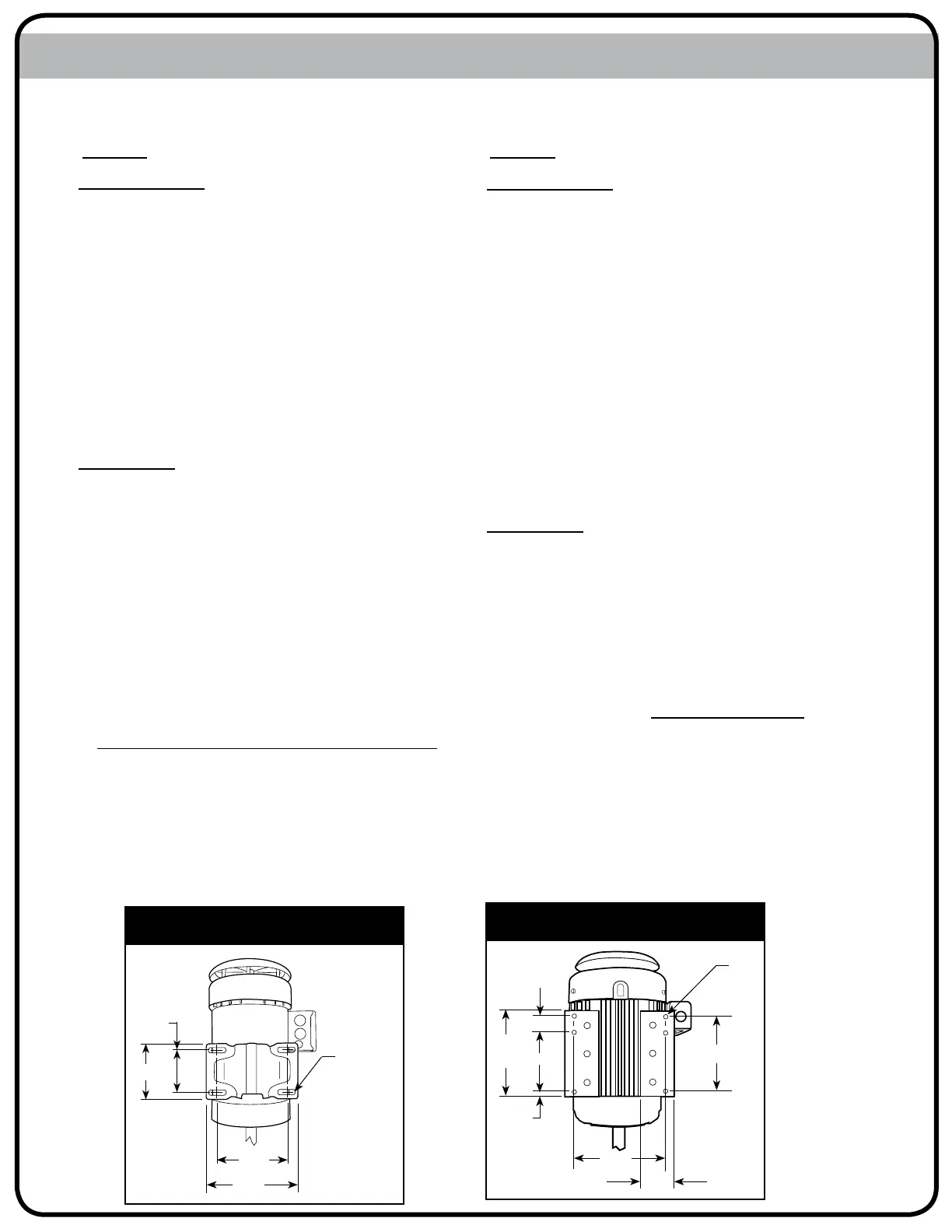

7-

1

/

2

”

7-

3

/

8

”

(ref)

3”

4-

1

/

2

”

5-

1

/

2

”

1”

3

/

8

”ø

15

/

16

”

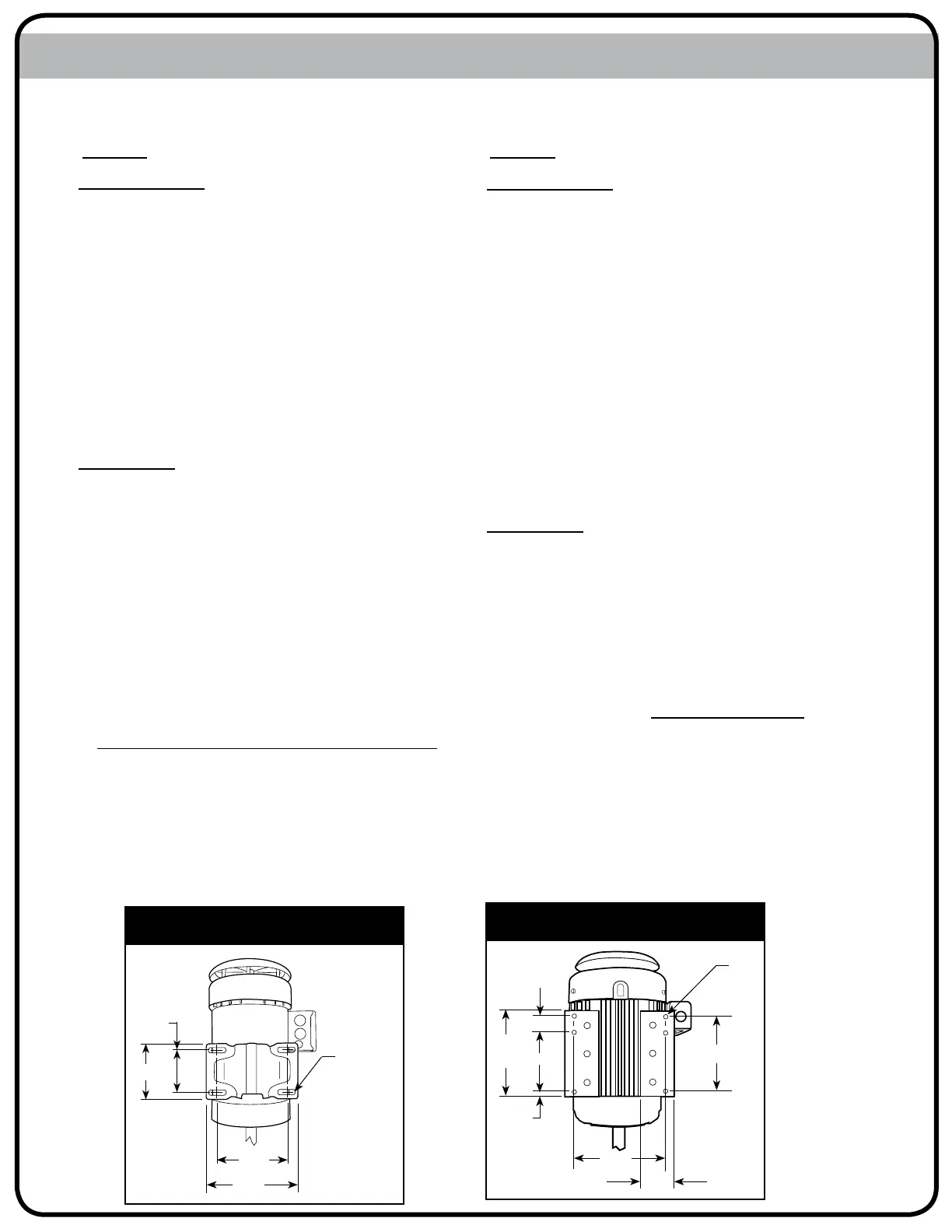

Mounting Diagram P3 - P7 1/2

Mounting Diagram P1/2 - P2

6.50”

4 SLOTS

.34 WIDE

4.88”

4.32”

3”

MODEL: P3, P5, P7-1/2

Loading...

Loading...