Installation 5

• Adjust switch according to switch

manufacturer’s instructions.

• Reconnect power supply to pump and

pump up pressure in system.

• Disconnect power supply to pump again

and re-check switch setting.

• Repeat until pressure switch starts pump

within ±1 PSI of proper setting.

• If cut-in setting is too low, system will

rattle or develop water hammer when

pump starts.

• Cut-out setting is not as critical as cut-

in setting. Make sure that pump will

stop running in a rea son able time. If it

does not, cut-out setting may need to be

adjusted down slightly. Be sure that after

readjustment, system does not rattle or

hammer on startup.

7. Re-check tank air pre-charge to be sure it is 2

PSI below pump pressure switch cut-in setting

(see Page 3).

TESTING FOR WATER CELL

LEAKAGE

1. Disconnect power to pump.

2. Drain all water from tank water cell by

opening faucet closest to tank.

3. Remove valve cap from valve and release all

pressure possible by depressing valve core.

When air stops coming from valve, remove

valve core to release remaining pressure.

4. Disconnect piping from elbow on tank flange.

5. Carefully turn tank upside down or lay it on

its side.

Retained water in tank may cause

sudden weight shift when lowering. Support

tank so that it cannot fall when being lowered or

inverted.

6. If water cell leaks, water will run out of valve.

If so, replace water cell.

WATER CELL REPLACEMENT

To be sure cover flange cannot

blow off of tank, release all air from system before

re moving nuts from cover flange.

1. Disconnect power to pump.

2. Follow steps 2 through 5 under “Testing For

Water Cell Leakage”, above.

3. Remove nuts from tank cover flange. Tap

cover flange to break seal and remove.

4. Water cell will not come out in one piece.

Hold water cell with pliers and cut wherever

convenient with single edge razor blade or

sharp knife. Continue holding and cutting

until water cell is removed.

5. Clean and dry inside of tank.

6. Before water cell can be inserted into tank, it

must be tightly rolled up as follows:

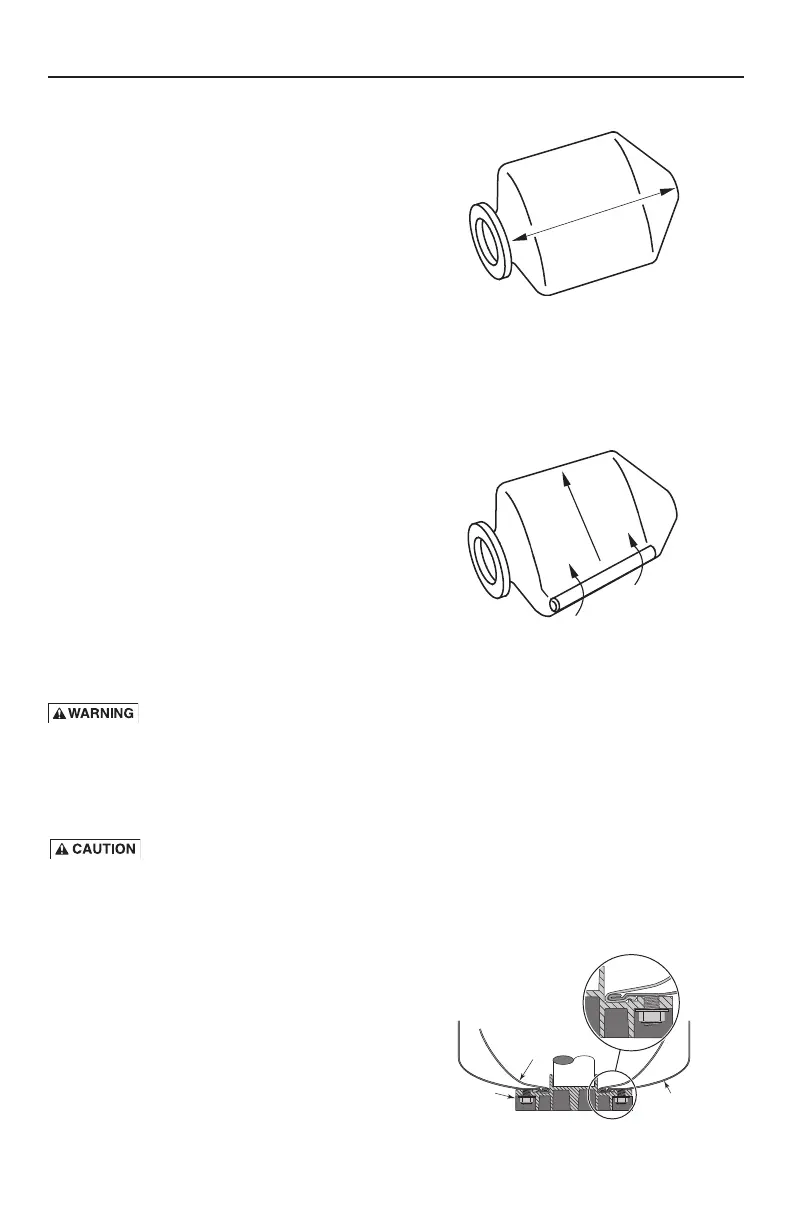

• Place water cell on clean surface with

opening to one end and flatten to force air

out. Pull ends out flat (see Figure 3).

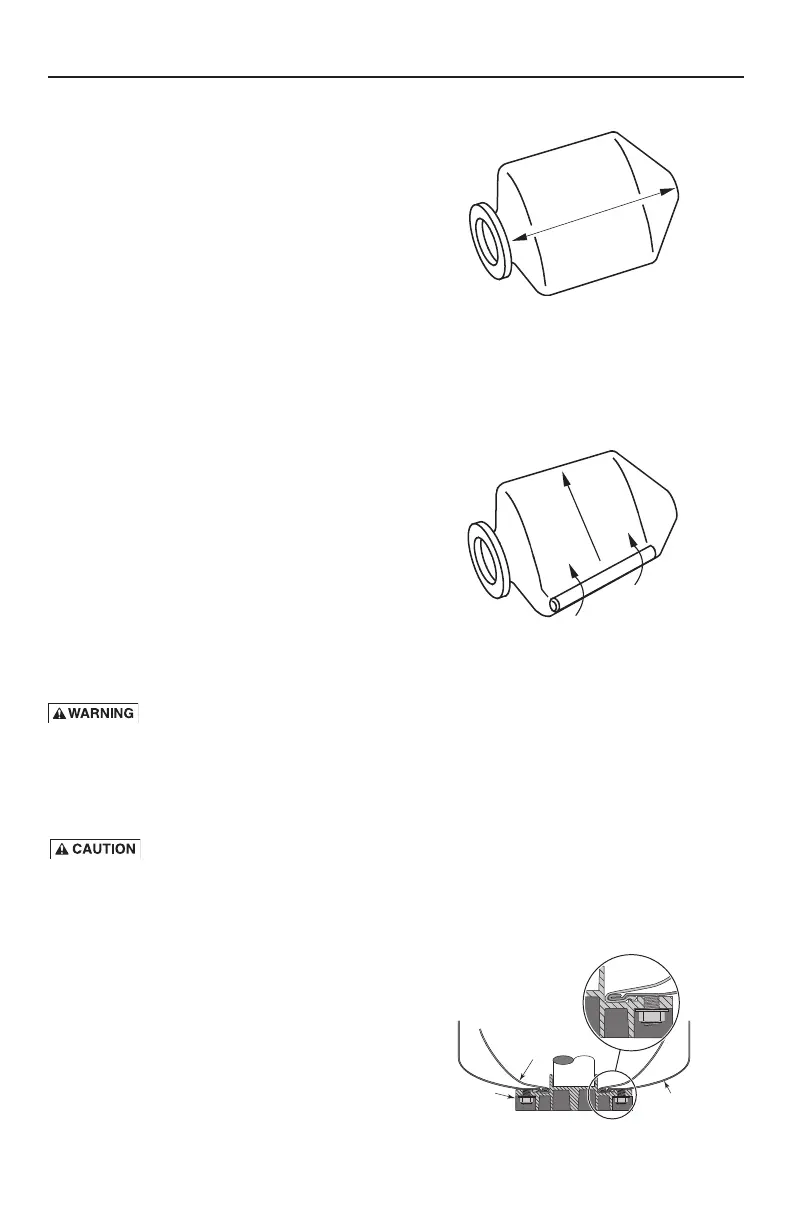

• To get tightest possible wrap, start on one

side at top and TIGHTLY roll water cell

diagonally to other side (see Figure 4). To

force out as much air as possible, be sure

to roll toward water cell neck opening.

7. To help insert water cell, sprinkle outside

of it with talcum powder. With tank on its

side, push tightly rolled water cell into tank,

hooking water cell neck ring over edge of

tank head.

8. Insert arm in water cell and push sidewalls

outward. It is not necessary to remove all

wrinkles from water cell.

NOTICE: Don’t push water cell into tank further

than its own length. In a large tank, water cell can

slip out of reach if pushed too far.

9. Clean tank head sealing surface and lip ring

groove of cover flange.

10. Pull lip ring of water cell through tank

opening and seat it against tank head.

11. Clean sealing surface and groove of cover

flange; place on tank (see Figure 5).

Figure 5 – Proper installation and

seating

Water

Cell

Tank

Wall

Cover

Flange

Figure 3 – Force all air out of water cell

Pull ends out flat

Figure 4 – Roll diagonally toward neck

Roll Diagonally

Loading...

Loading...