15192 Triton Lane

Huntington Beach, CA 92649

Tel: 206-888-6251

www.ppedm.com

e

●

drill

TM

QUICK START & MAINTENANCE GUIDE

This document is the property of PPedm, Inc. and contains proprietary and/or patented information and may not be reproduced in part or in whole without the express written permission of

the company. Perfect Point logo, Perfect Point

TM

and e●drill

TM

are trademarks of PPedm, Inc.. US and worldwide patents pending.

MAINTENANCE REQUIREMENTS:

Periodic maintenance is required to keep this system operating properly, most critical of which is gun maintenance, described below. System

maintenance is controlled by internal firmware cut cycle counters that shut down the system for maintenance once a maintenance cycle is reached.

Once the predetermined cut cycles are reached operator intervention is required to perform maintenance and reset the counters.

BG/CG GUNS ONLY: Properly setting and maintaining the Ground Pin is critical to proper e•drill

operation. Failure to properly set and maintain the Ground Pin will cause poor e•drill performance

and cutting results, and will potentially damage the system.

BG/CG GUNS ONLY: DAILY the condition of the end of the Ground Pin and its protrusion should be checked with

the Ground Pin Setting Tool (P/N EDT0102) provided with the system. The ground pin is extremely fragile and an

electrode should be attached at all times to protect the ground pin. The ground pin should not be bent and should be

central inside the electrode, and it should still have its protective plastic sleeve intact. Adjust as necessary and dress

with the abrasive pad located on the setting tool if the tip is fouled. Consult the User’s Guide for further details.

ALL GUNS: Check Cable, Strain Relief and Case for damage. Check for water leaks out of Case. Check

Electrode is tight. When cutting steel fasteners: At the end of a work session the tip of the gun should be

dried, and if it has been used on a highly corrosive fastener material such as alloy steel, then the inside of

the tip area should be lightly sprayed with a lubricant such as WD40.

BG/CG GUNS ONLY: If the ground pin is maintained as above, and fastener heads are cleaned before attempting to

cut, ground pin replacement is only necessary after several thousand cut operations.

Refer to the User Guide - Ground Pin Replacement section for detailed instruction on replacing the Ground Pin.

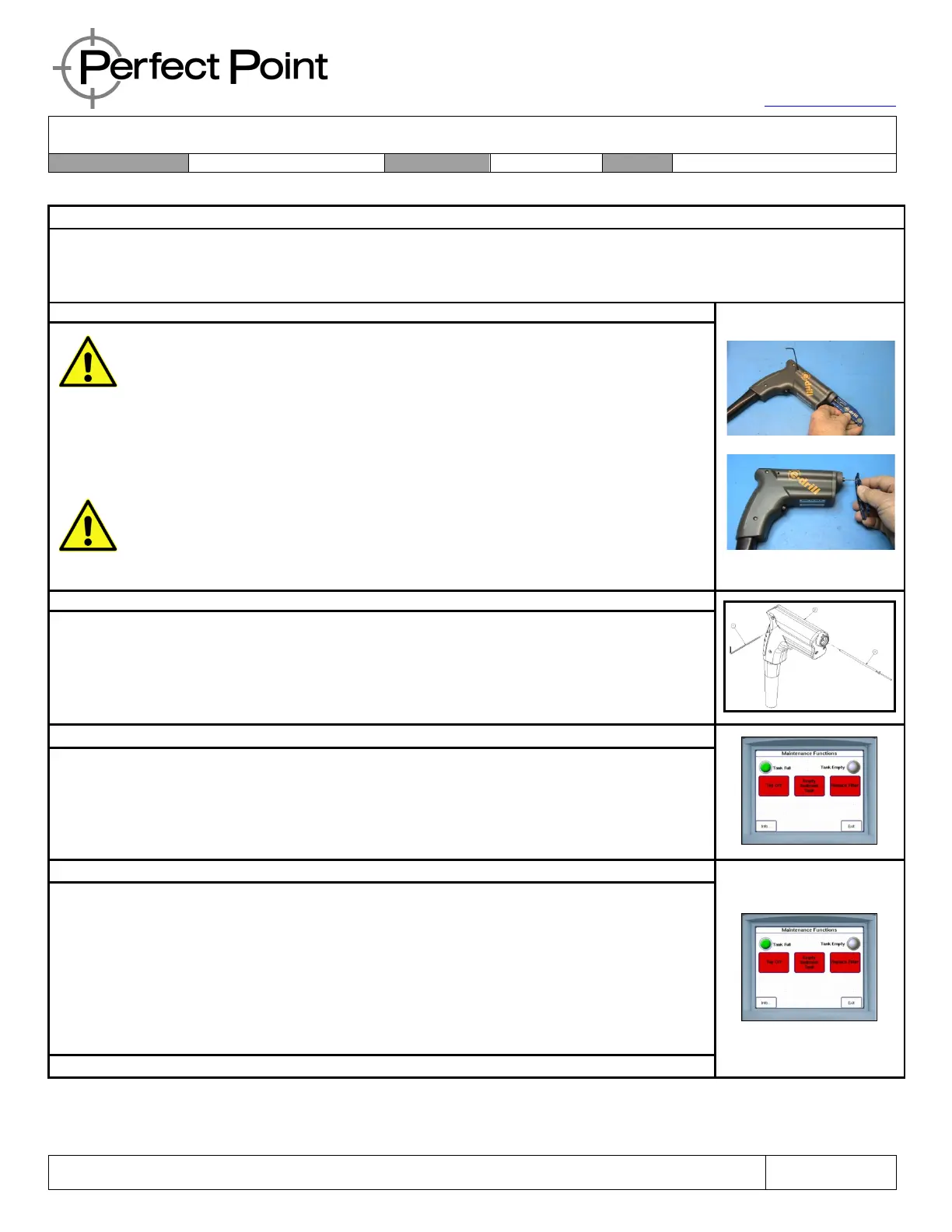

System Maintenance Screen:

System maintenance functions are accessed through the System Maintenance Screen. Touching an LED button will

turn the button green (on) and activating the function. Retouching the button will turn the function off and the button

back to red (off). The Tank Full and Tank Empty LED’s display system water level status in the Sediment Tank and

turn on and off automatically as the system is serviced.

DI water system maintenance:

The DI water system requires periodic filling or “Top Off” to replace small amounts of DI water used in the cutting

cycle. The system will indicate when that is necessary. To “Top Off”, Immerse the tip of the e

•

drill

TM

(do not submerge

the entire drill, only the Adapter Tip should be submerged).Touch the Top Off function. At the completion of the Top

Off cycle the Tank Full LED button will illuminate green when the system is full and the pump will turn off

automatically.

The system will also indicate when the sediment tank should be emptied or the filter replaced. Consult the Users

Guide for the relevant procedures.

For additional support assistance call the Customer Service Line at: (714) 891-6533.

Loading...

Loading...