4

5

OPERATION

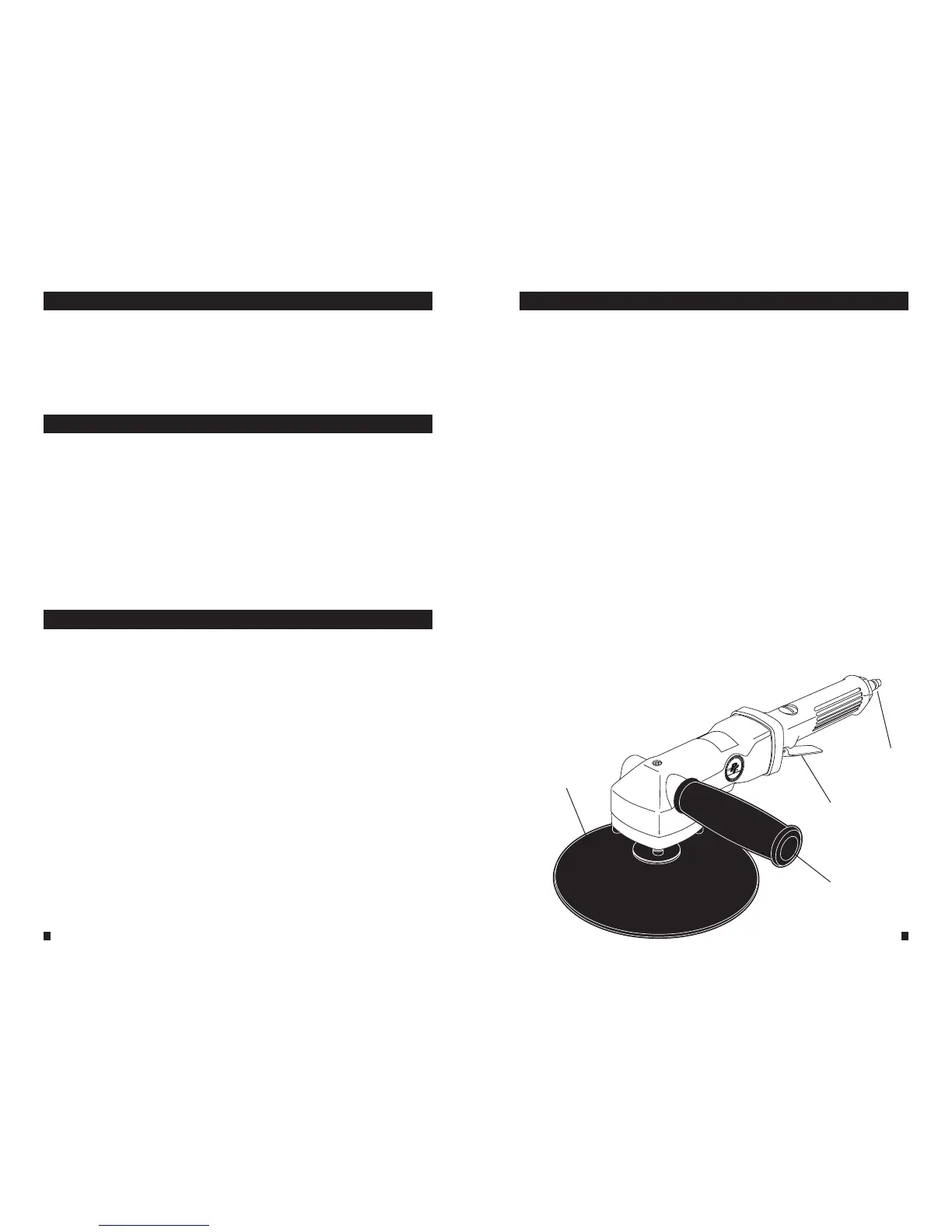

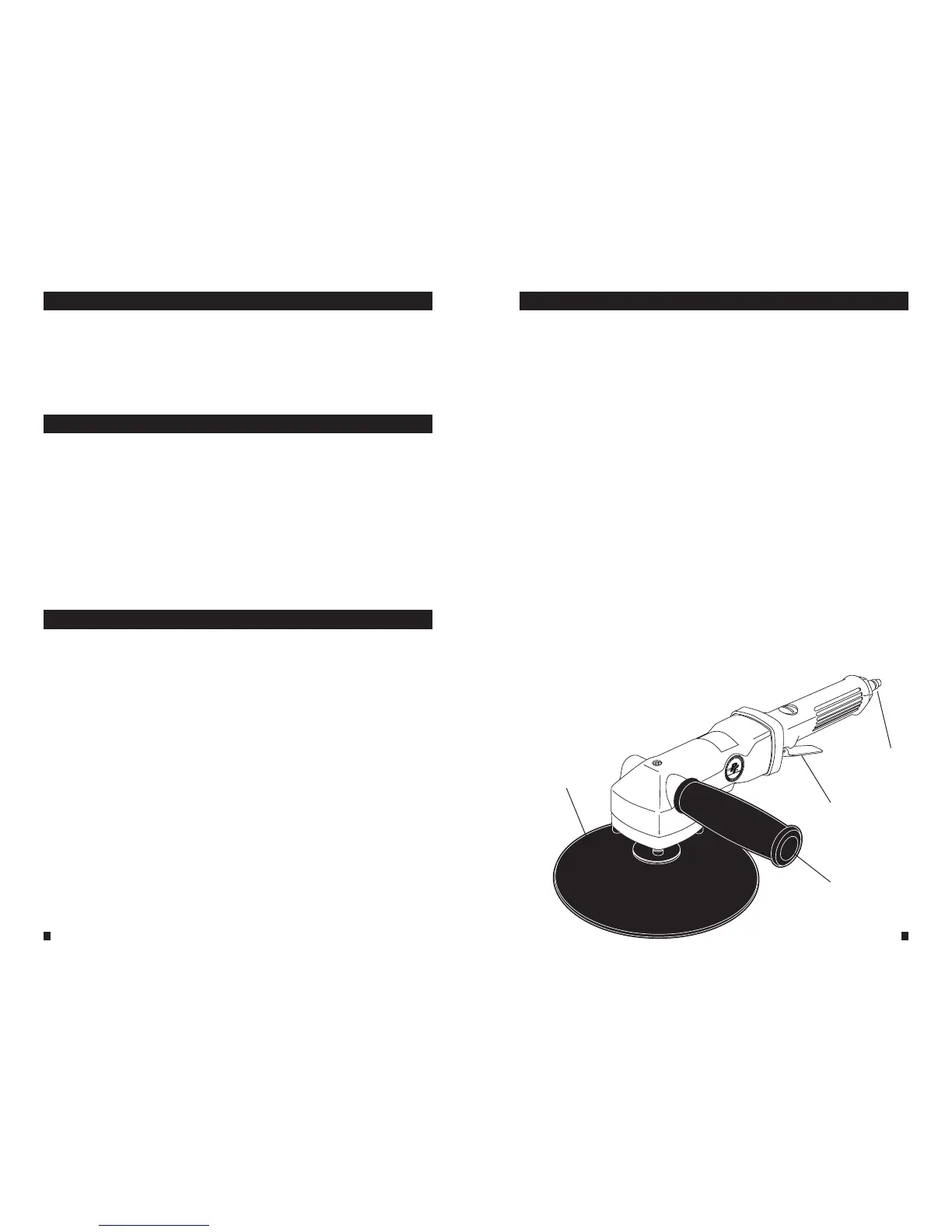

Pad

Handle

Air Inlet

Trigger

ASSEMBLY

1. Thread the Side Handle (30) into the side of the Gear Housing (27) until tight.

2. Thread raised side of Pad onto Lock Nut (45).

3. Place the grinding wheel or backing pad onto Lock Nut (45).

4. Thread Sealing Ring (5) onto Lock Nut (45) making sure at edge faces out.

5. Place Wrench (44) on Arbor (34) and the Lock Nut Wrench (43) on the Lock Nut

(45) and tighten.

SETUP

1. Designate a clean and well-lit work area. Work area must not allow access by children

or pets to prevent distraction and injury.

2. Route the air hose along a safe path to reach the work area without creating a tripping

hazard or exposing the air hose to possible damage. Make sure air hose is long

enough to reach work area with enough slack to allow free movement while working.

3. Secure loose work pieces using a vise or clamps to prevent movement while working.

4. Make sure there are no hazardous objects (such as utility lines or foreign objects)

nearby that will present a hazard while working.

5. If an automatic oiler is not used, put a few drops of Pneumatic Tool Oil into tool at air

inlet connection before use. Add a few more drops after each hour of continual use.

6. Set the compressor to 90 PSI.

OPERATION

Sanding Instructions:

1. Position the sanding disc (sold separately) in the center of the Pad, making

sure there is equal overhang on the disc.

2. Grip tool with both hands and place onto the area to sand.

3. Squeeze the Trigger (14). You can vary the speed of the tool to suit your

needs by varying the amount of pressure applied.

4. Move tool in a uniform pattern, either up or down or side to side to ensure

even sanding.

5. Periodically check tool for any potential disc wear. Replace used disc when

necessary.

Grinding Instructions:

1. Attach grinding wheel as indicated in Assembly.

2. Grip tool with both hands and place onto the area to sand.

3. Squeeze the Trigger (14). You can vary the speed of the tool to suit your

needs by varying the amount of pressure applied.

4. Move tool in a uniform pattern, either up or down or side to side to ensure

even grinding.

5. Periodically check the tool for any potential wear. Replace used grinding

wheel when necessary.

Polishing/Bufng Instructions:

1. Attach a polishing bonnet (sold separately) and apply a small amount of

the appropriate polishing compound onto the bonnet in a circular (or swirl)

fashion.

3. Grip toool with both hands and place tool onto the area you wish to polish.

4. Squeeze trigger (14) halfway down. Move the tool in a random pattern.

CAUTION! Do not polish in one position for more than a few seconds.

5. Once you've covered the desired area, stop and replace bonnet with a new

bonnet for bufng operation.

6. Avoid polishing body part edges. Use hand force to prevent possible damage

to auto body nish.

7. Buff polished area the same way, applying light pressure and moving in a

random pattern until the compound has been removed.

8. Use a clean, lint-free cloth to remove any compound from crevices that could

not be reached with Tool.

9. If the tool requires more force to accomplish the task, verify that the tool re-

ceives sufcient, unobstructed airow (CFM) and increase the pressure (PSI)

output of the regulator up to the maximum air pressure rating of this tool.

CAUTION! To prevent tool and accessory failure, resulting in injury: Do not

exceed tools maximum air pressure rating.

10. If tool still does not have sufcient force at maximum pressure and sufcient

airow, a larger tool may be required.

11. To prevent accidents, turn off the tool, detach the air supply, safely discharge

air pressure, and release the trigger. Clean external surfaces of the tool with

clean, dry cloth, and apply a thin coat of tool oil.

Then store the tool indoors out of children's reach.

Loading...

Loading...