Do you have a question about the Perkins T6.3544 and is the answer not in the manual?

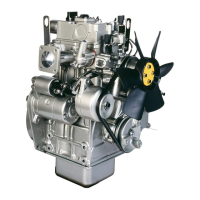

Lists and identifies various engine components shown in diagrams.

Provides performance specifications like kW, bhp, and rev/min for different engine applications.

Lists crucial torque values for fasteners during engine assembly and maintenance.

Contains detailed measurements and tolerances for engine components like cylinders and pistons.

Details piston dimensions, ring gaps, and specifications for various engine models.

Provides specifications for crankshaft journals, main bearings, and connecting rod bearings.

Contains specifications for valve guides, valve seats, and related components.

Lists static timing, engine angle, and fuel pump marking angles for different injection pumps.

Specifies acceptable wear limits for engine components to determine serviceability.

A diagnostic table correlating engine faults with their possible causes.

Step-by-step instructions for safely removing the cylinder head assembly.

Procedure for correctly installing the cylinder head assembly, including torque sequences.

Guidance on how to check and adjust valve tip clearances for optimal engine performance.

Instructions for removing and installing valves, including related components.

Details on cylinder head valve guides, including wear and fitting procedures.

Procedure for safely removing pistons and connecting rods from the engine.

Instructions for inspecting piston ring gaps and assembling rings to pistons.

Guidance on checking piston ring condition and ensuring correct gap clearance.

Procedures for inspecting cylinder block bores and renewing cylinder liners.

Detailed steps for replacing cylinder liners in the block.

Instructions for replacing crankshaft thrust washers.

Procedures for removing and reinstalling the crankshaft.

Details on acceptable tolerances and procedures for regrinding crankshaft journals.

Procedure for replacing the crankshaft rear oil seal.

Steps to remove the timing case, camshaft gear, and auxiliary drive gear.

Procedure for correctly reinstalling the timing case and associated gears.

Instructions for removing the camshaft and tappets.

Procedure for removing the auxiliary drive shaft and fuel pump drive shaft.

Guidance on checking the backlash between timing gears.

Explanation of timing marks and procedure for setting Top Dead Centre (TDC).

Procedure for resetting the engine's basic timing.

How to check the timing of CAV and Bosch fuel injection pumps.

Procedure for checking and verifying valve timing.

Schematic illustrating the flow of lubricating oil through the engine.

Step-by-step instructions for removing, dismantling, and reassembling the oil pump.

Procedures for removing, dismantling, and testing oil coolers.

Instructions for replacing the engine's lubricating oil filter element.

Description of coolant flow and maintenance of fan belts.

Procedures for draining the cooling system and replacing thermostats.

Step-by-step instructions for removing and reinstalling the water pump.

Procedure for fitting a new water seal to the water pump.

Explanation of the function and positioning of piston cooling jets.

Describes different air cleaner types and their cleaning procedures.

Details on fuel lift pump function, checking pressure, removal, and refitting.

Explanation of fuel injection pump operation and procedures for checking timing.

Troubleshooting guide for removing air from the fuel system.

Instructions for removing and reinstalling the engine flywheel.

Procedures for removing and reinstalling the flywheel housing.

How to measure flywheel runout and check against specifications.

Routine maintenance procedures for the turbocharger.

Guidance on diagnosing and troubleshooting common turbocharger problems.

Steps involved in reconditioning a turbocharger unit.

Procedures for dismantling specific turbocharger models and cleaning components.

General description of alternator operation and safety precautions.

Troubleshooting common electrical faults related to the alternator.

Description of starter motor operation and routine maintenance.

Methods for testing the alternator's output and performance.

Steps for testing the starter motor's functionality on the application.

Detailed instructions for dismantling the Clayton Dewandre SC6 compressor.

Steps for removing and dismantling cylinder head and piston assemblies.

Guidance on inspecting compressor parts and checking wear in the bore.

Instructions for correctly reassembling the compressor after service.

Provides technical data, dimensions, and torque specifications for compressors.

Comprehensive steps for overhauling the exhaust system components.

Instructions for replacing seals and reassembling the drive end cover.

| Engine Model | T6.3544 |

|---|---|

| Engine Type | Diesel |

| Number of Cylinders | 6 |

| Aspiration | Turbocharged |

| Fuel System | Direct Injection |

| Cooling System | Liquid Cooled |

| Displacement | 5.8 L (354 cu in) |

| Bore | 98.4 mm (3.875 inches) |

| Stroke | 127 mm (5.0 in) |

| Power Output | 120-170 hp (depending on configuration) |

| Torque Output | 434-542 Nm (320-400 lb-ft) depending on configuration |

| Weight | 600 kg |