Refit the road wheel

beÍore

lowering

the car to the

ground,

adlust the

brakes as detailed

in

Section

10:2.

Reassembling lefthand

front brake :

1

Remove

the

wire from around the brake cylinder and

piston.

2 Position the brake shoes against the

brake

plate

and

secure

with

the

lateral

springs. The offset end

oÍ

the

brake shoes should be located in

the

same manner as

Íor the righthand

brake, r.e.

Towards the front

for the upper brake shoe.

Towards the rear for the lower brake

shoe.

3

Install both inner

springs, using the brake tool, in the

Íollowing manner:

Position

the springs

between

the brake

shoes and

the brake

plate

and engage

the small

hook

oÍ each

spring

in

the corresponding holes in the brake shoes.

Engage the tool, hook

'a',

in

the spring hook and

rotate tool

around the Íixed

point.

At the same time

pull

on

the tool

until

it is

possible

to engage the

spring

hook.

Remove the tool.

4

Install the outer springs. The larger hooks

oÍ the

inner

springs may be closed slightly after f itting if

necessary.

5

ReÍit

the brake

drum to the hub and adtust the

brakes.

Brake

shoe springs:

All the brake shoe inner return springs

are

identical

and

incorporate

26 turns.

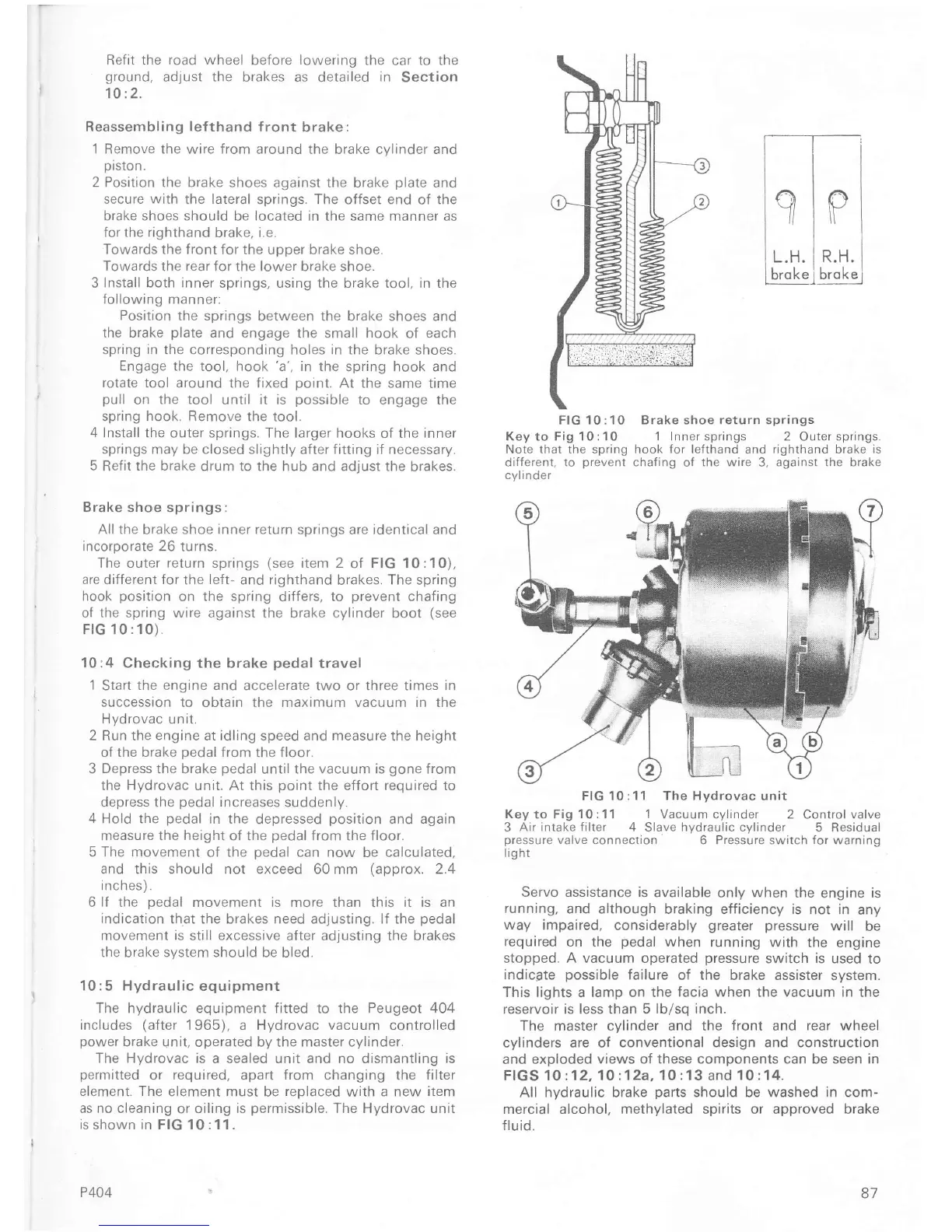

The outer

return

springs

(see

item 2

oÍ

FIG

10:10),

are different for the left' and righthand

brakes.

The

spring

hook

position

on

the spring

difÍers, to

prevent

chafing

of

the

spring

wire against the brake cylinder

boot

(see

FIG 10 : 10).

10:4

Checking the brake

pedal

travel

1

Start

the engine and accelerate

two or

three

times

rn

succession to obtain the maximum vacuum in the

Hydrovac

unit.

2 Run the engine at idling

speed

and measure

the height

of the brake

pedal

from

the

Íloor.

3 Depress the brake

pedal

until the

vacuum is

gone

from

the

Hydrovac

unit. At this

point

the effort

required

to

depress

the

pedal

increases

suddenly.

4

Hold the

pedal

in the

depressed

position

and again

measuíe

the height

of the

pedal

from the floor.

5

The movement of the

pedal

can

now be

calculated,

and this should not exceed 60 mm

(approx.

2.4

i n ches) .

6 lf

the

pedal

movement is more than thls it is an

indication

that the brakes need adjusting. lf the

pedal

movement

is

still

excessive

aÍter adjusting the brakes

the

brake

system

should be bled.

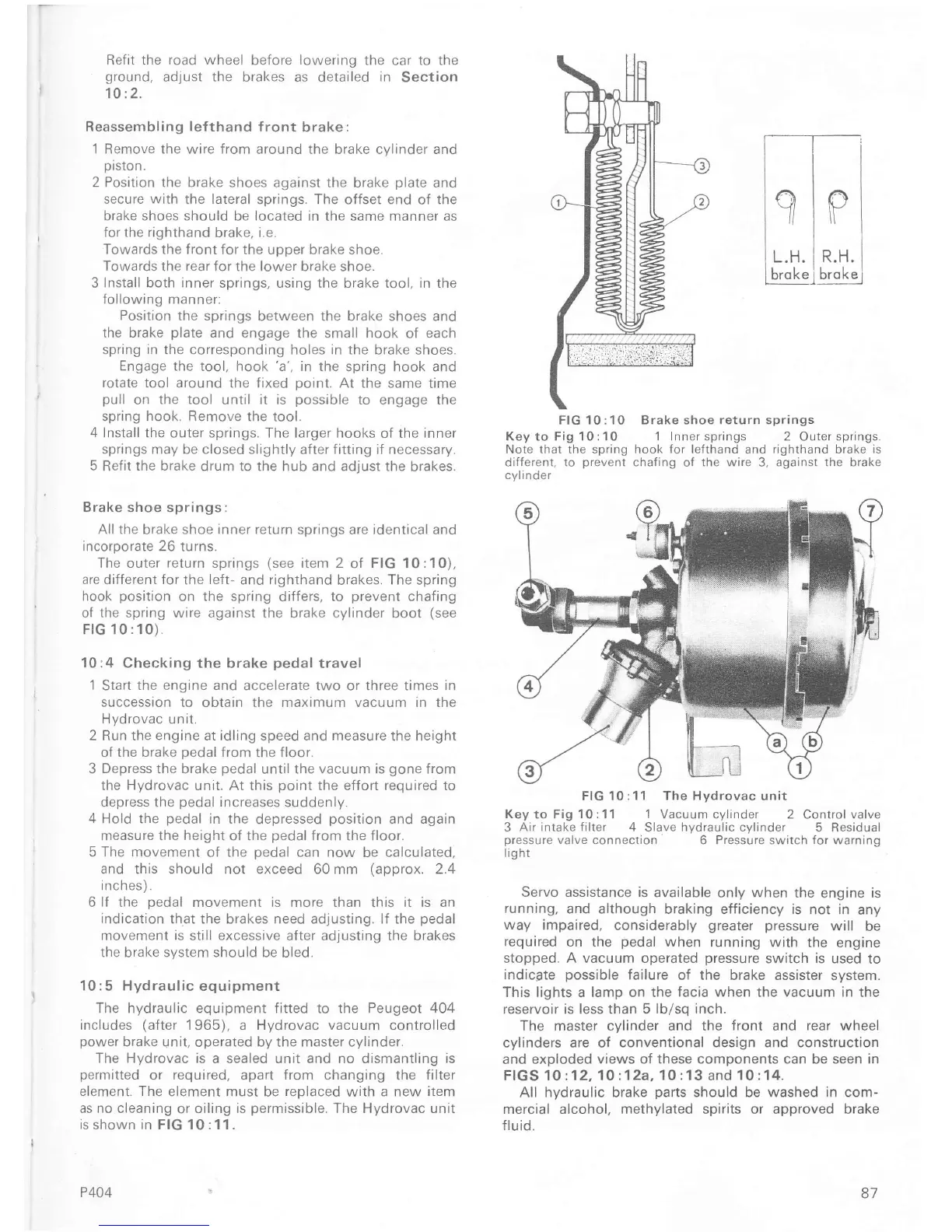

10:5 Hydraulic equipment

The hydraulic equipment fitted to the Peugeot

404

includes

(after

1965), a Hydrovac vacuum controlled

power

brake

unit,

operated by the master cylinder.

The Hydrovac is

a sealed unit and no dismantling

is

permitted

or required, apart from changing

the

filter

element. The element must

be

replaced

with a new

item

as no cleaning

or

oiling is

permissible.

The Hydrovac unit

is

shown in FIG 10 : 1 1 .

P404

FIG

10:10 Brake shoe

return

springs

Key to Fig 10:10

1 Inner

springs 2 Outer springs.

Note that the spring hook

Íor

leÍthand and righthand brake

is

diÍJeÍent, to

prevent

chaÍing

of

the wire

3,

against the brake

cyilnoer

FIG 10:11

The Hydrovac

unit

Key

to Fig

10:11 1 Vacuum

cylinder 2 Control valve

3

Air intake filter

4 Slave hvdraulic cvlinder 5

Resiouar

pressure

valve connection

6 Pressure switch

for

warning

lig ht

Servo assistance is

available

only

when

the engine is

running,

and although braking efficiency is

not in

any

way

impaired,

considerably

greater pressure

will

be

required

on the

pedal

when

running with the

engine

stopped. A

vacuum

operated

pressure

switch

is

used to

indicate

possible

failure

of the brake assister system.

This lights a lamp on the

facia

when the vacuum in the

reservoir is less than 5

lb/sq inch.

The master cvlinder and the

front

and

rear

wheel

cylinders are

of conventional design and construction

and exploded

views oÍ these components can be seen in

FfGS 10:12,

1O:12a,1O:13

and

í0:14.

All hydraulic

brake

parts

should be washed in com-

mercial alcohol, methylated spirits or appÍoved brake

f lu id.

87

Loading...

Loading...