Do you have a question about the Pfaff 330 Automatic and is the answer not in the manual?

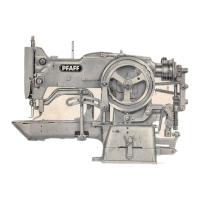

Explains the role of essential sewing machine parts.

Details needle types, sizes, and proper insertion.

Describes the function and type of the sewing hook.

Explains the take-up lever's function in thread control.

Explains the feed dog's role in moving material.

Details how to regulate upper and lower thread tension.

Explains how the zigzag stitch is created and adjusted.

Guidelines for storing machine heads and cabinets.

Procedures for checking and oiling cabinet/stand parts.

How to adjust presser foot pressure for different fabrics.

Causes and remedies for skipped stitches.

Common causes and solutions for needle thread breakage.

Details the components of the machine's sewlight.

Notes on power cords and plugs.

Explains the rheostat for speed control.

Adjustments related to the arm components of the machine.

How to adjust the feed eccentric for timing.

Correct positioning of the belt sprocket on the top shaft.

Adjustment of the large bevel gear and needle vibrating eccentric.

Setting the driving eccentric for the automatic mechanism.

Procedure to zero the needle for straight stitching.

How to center the needle in the needle hole for straight stitches.

Steps to adjust the needle for symmetrical zigzag stitching.

Detailed procedure for timing the sewing hook.

Specific instructions for timing the hook on the PFAFF 230.

Specific instructions for timing the hook on the PFAFF 332.

Adjusting the position finger bracket for correct thread loop passage.

Procedure for setting the correct height of the needle bar.

Sideways and lengthwise adjustment of the feed dog.

Using gauges to set presser bar and feed dog height.

Adjustment of the drop feed mechanism.

Setting the correct height of the needle threader cam.

How to adjust the bobbin winder for even winding.

Procedures for replacing and timing the thread check spring.

Details on the new type of upper thread tension mechanism.

Explains the overall function of the automatic mechanism.

Troubleshooting stitch width changes.

Causes and remedies for irregular pattern movement.

Fixing asymmetric patterns from specific settings.

Troubleshooting patterns that are incomplete or irregular.

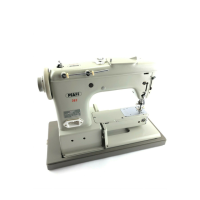

| Model | 330 Automatic |

|---|---|

| Bobbin Type | Class 15 |

| Type | Sewing Machine |

| Stitch Types | Straight, Zigzag, Buttonhole |

| Needle Position | Left, Center, Right |