7.

Changing the needle

Raise the needlo

bar

to its highest point, loosen the needle set scrnw half n turn, and

pu

ll the damaged n

eed

le

ou

t

of

the needle cl

am

p.

Insert

a

new

naodlo into the clamp. making sure thai

i1s

short groove faces toward the

sowing hook. Push the needle

up

as

tat

as

it

will

go and tighten the r.ecdle set screw

securelY.

Never use rusty n

oo

dles.

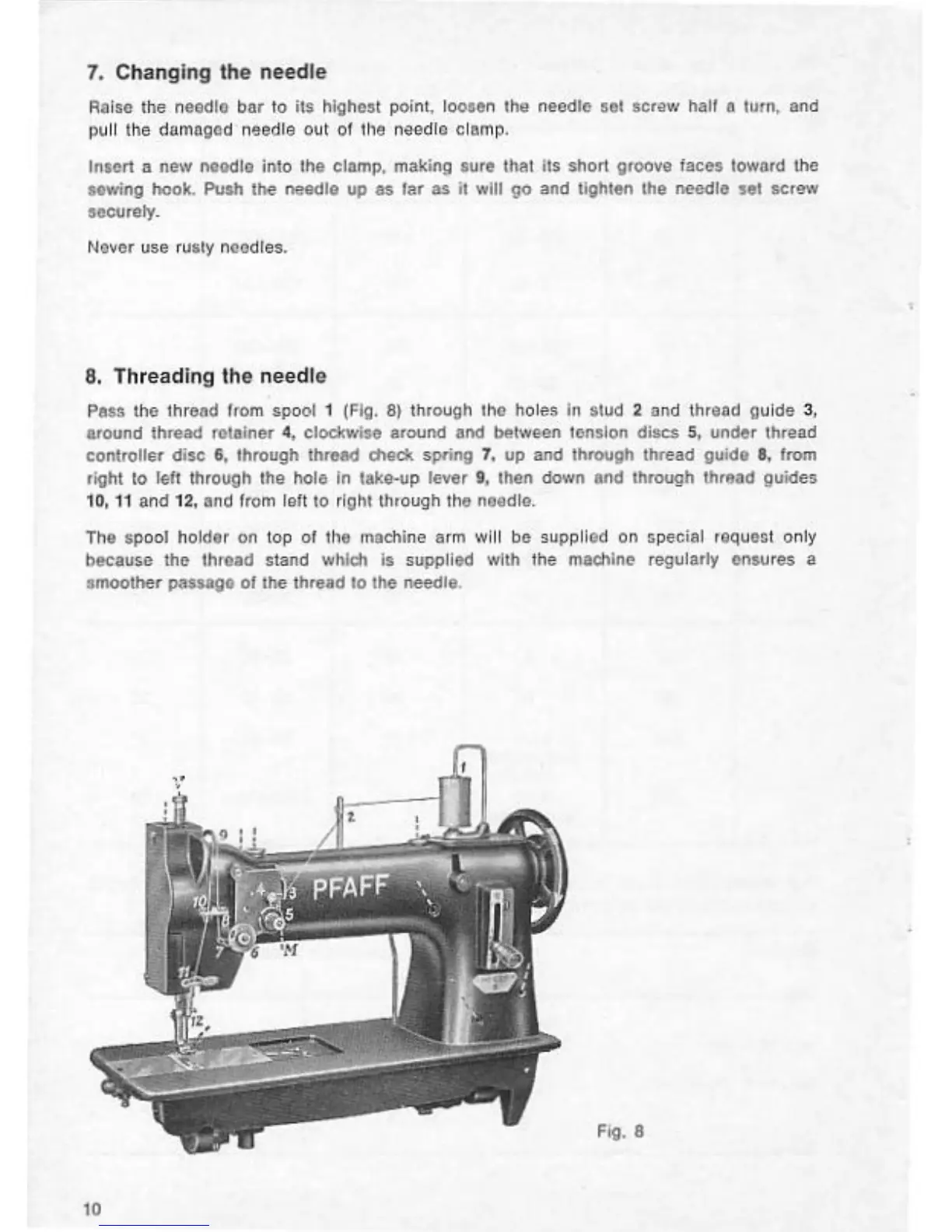

8.

Threading the needle

Pes•

the thro

nd

from spoof 1 fFtg.

81

through tho hol

es

in stud 2 and thread guide 3,

around thread rotainer 4, clockwise around and between tonslon discs

5,

under thread

controller

disc

&.

through thread

dleck

spring

7.

up

and through thread guide 8, from

right to

left through the hole In take-up lever

9,

then down and through thread guides

10,

11

and 12. ond from left to right through the needle.

The

sp

ool holder on top

of

the 1nachine arm

will

be suppli

ed

on opecial r

eque:J

t oniy

because

the thread stand which

is

supplied with

1he

machine regularly On$ures a

smoother passago

of

1he

thread to the needle.

F1g.

8

10

Loading...

Loading...