GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

21

9.2.2 Standard screw jack with trapezoidal thread screw

Safety test:

The wear of the nut thread in the worm wheel / in the travelling nut needs

to be checked regularly, at least once per year.

Replacement is urgently required once the wear limit has been reached.

X = maximum wear (see Table 9.2.1)

9.2.3 Standard screw jack with ball thread screw

Safety test:

Pay attention to the running noises of the Ku screws during operation. An increase in noise indicates

wear of the Ku nuts. The nuts and screws need to be replaced promptly.

The Ku screws/nuts should generally be exchanged at the end of its service life.

9.2.4 Safety screw jacks

For utilisation in systems in acc. with EN 280, EN1570-1, EN1593; DIN 56950-1

In accordance with BetrSichV, lifting equipment must undergo an examination by an authorised person in

intervals (at least 1x per year) specified by the operator (TRBS 1203-1).

8

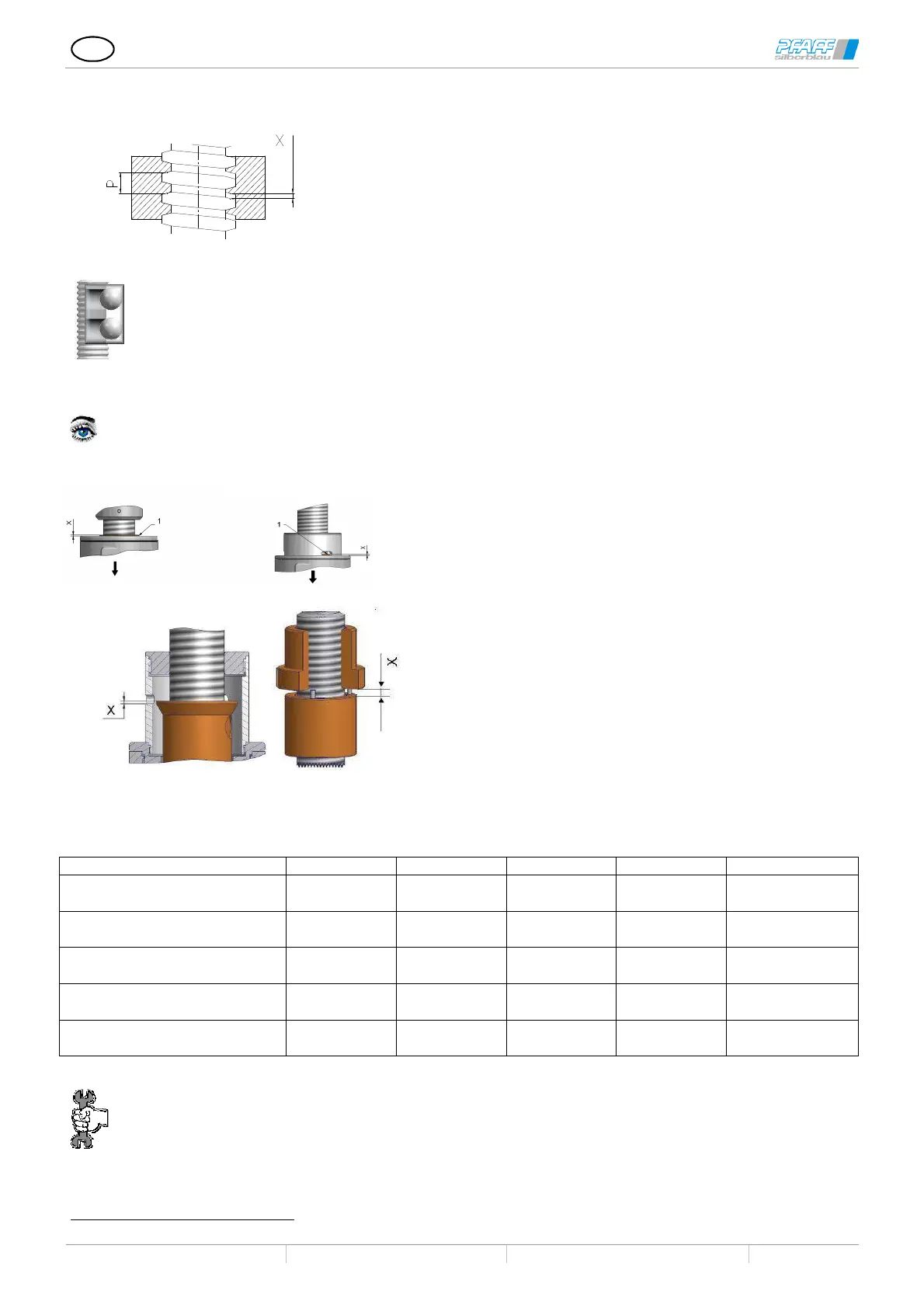

9.2.5 Screw jacks with safety nut

1 = Wear indication ring

Safety test:

Check the wear in the screw jacks (dimension x) of the

translation thread in the worm wheel / travelling nut.

Prompt replacement of the carry nut and safety nuts is

required should the safety nut (wear indication ring) align

with the upper and lower edge of the housing or the wear

limit has been reached (dimension X).

Wear limit = X - max. wear

(see Table 9.2.1)

9.2.6 Wear measurement log

We recommend recording the new condition and the results from measuring the wear (dimension

X).

Screw jack 1 Screw jack 2 Screw jack. 3 Screw jack 4 Date/Signature

New condition

Dimension X

Wear measurement

on _____________

Wear measurement

on _____________

Wear measurement

on _____________

Wear measurement

on _____________

9.2.7 Spindle lubrication

Clean the screw with grease evenly with a brush.

We recommend an automatic lubricant dispenser in places of difficult accessibility, a longer power time or in

dirty environments.

Automatic lubricant dispensers are also available with ATEX conformity.

8 We recommend having this check performed by the service department of CMCO.

Loading...

Loading...