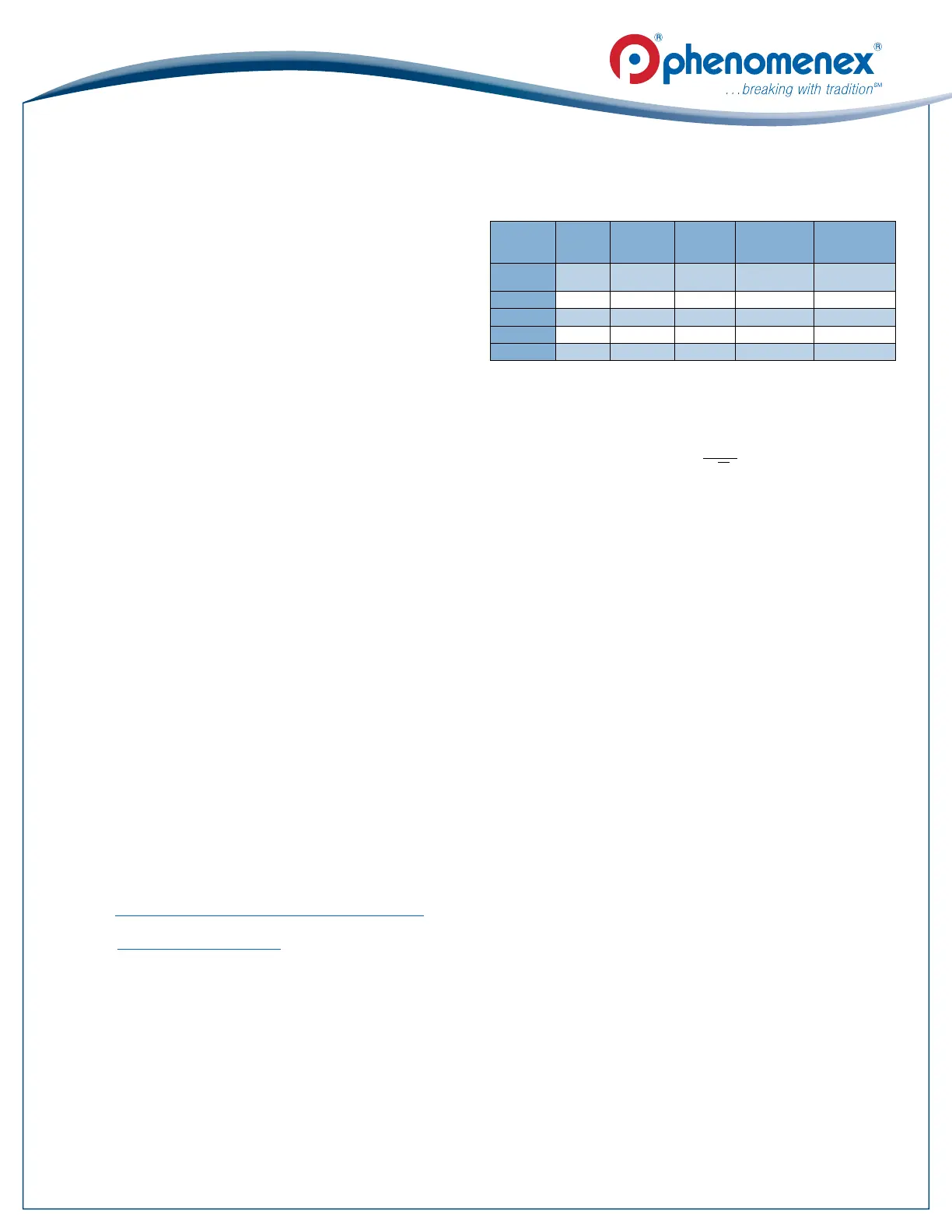

Amounts of Sample That Can Be Separated

Column Type ID (mm)

Approx.Dead

Volume (mL)*

Typical Flow

Rate (mL)

Typical and

(Max.) Injection

Masses (mg)

Typical and

(Max.) Injection

Volumes (μL)**

Capillary

(Fused Silica)

0.32 0.0075 0.001 - 0.02 0.001 (0.01) 1 (10)

Microbore 1.0 0.07 0.02 - 0.1 0.01 (0.1) 5 (25)

Analytical 4.6 1.5 0.5 - 2.0 0.1 (2.5) 10 (200)

Semi-Prep 10.0 7.3 5.0 - 20 1.0 (25) 50 (1000)

Preparative 20.0 29.2 10 - 200 5.0 (500) 200 (5000)

*The column Dead Volume (Vo) may be estimated from:

Column Dead Volume (mL) = Vo = 0.487 x d

2

x L

Where: L = column length (cm); 15 cm (150 mm) used for calculation.

d = column ID (cm, not mm)

**The maximum allowable Sample Injection Volume (Vi) can be estimated as

follows: Maximum Injection Volume

Where: Vr = the retention volume of the rst peak (mL)

N = number of theoretical plates per column

Tips for Extending Column Lifetime

• Utilize sample preparation techniques such as solid phase extraction

(Strata

®

-X SPE products) or accessories (Phenex

™

Syringe Filters) to

minimize the injection of unwanted contaminants onto your system

and column.

• Use the correct guard column or guard cartridge system (SecurityGuard

™

) to

help remove particulates before they foul your column.

• Do not overload your column. Inject suitable sample concentrations and

volumes.

• Work in the appropriate separation mode for the column. Please see

Column Characteristics chart for typical modes each stationary phase

is used for.

• Store your column in appropriate solvent(s).

• Solvent switch correctly by slowly acclimating the phase from one

miscible solvent to the other at a low ow: 0.1 mL/min for 2.1 mm ID and

0.5 mL/min for 4.6 mm ID.

Column Warranties

Phenomenex HPLC columns are warranted to meet the stated performance

and quality and to be free of defects in material and workmanship. If you are

unsatised for any reason, please give your Phenomenex Technical Representa-

tive a call. We’ll do our best to solve the problem to your satisfaction. Should it

become necessary to return the column, a Return Authorization Number must be

obtained from Phenomenex rst.

Disclaimers

New columns should be tested with the manufacturers recommended test mix,

and previously used columns should be tested with the same or a suitable test

mix for the analysis. Remember to re-equilibrate the system when changing

solvents. Never change from one solvent to another which is immiscible, without

going through an intermediate solvent which is miscible with both. This will dam-

age the column. Never change to (or from) a buffer/salt solution where the buffer/

salt is not soluble in the second solvent. Again this will damage the column.

Never attempt to remove the column end ttings. This will void the warranty.

Column Shock

Handle columns with care. Do not drop or create physical shock. Do not start

pump at high ow rates, instead ramp up gradually over a few minutes. Set your

pump pressure limit to protect the column in event of blockage. This can create

voids which will detrimentally affect the column’s performance.

Column Questions and Support

If you have any additional questions, please reach out to our amazing technical

team through:

Email: support@phxtechnical.zendesk.com

Live Chat: https://www.phenomenex.com/info/page/2015phenomchat

For more information on Gemini UHPLC, HPLC, and Preparative columns,

please visit www.phenomenex.com/Gemini

Trademarks

Phenomenex, Gemini, and Strata are registered trademarks, Phenex and SecurityGuard are

trademarks of Phenomenex.

Gemini is patented by Phenomenex. U.S. Patent Nos. 7,563,367 and 8,658,038 and foreign

counterparts.

SecurityGuard is patented by Phenomenex. U.S. Patent No. 6,162,362

CAUTION: this patent only applies to the analytical-sized guard cartridge holder, and does not apply to SemiPrep,

PREP or ULTRA holders, or to any cartridges.

Strata-X is patented by Phenomenex. U.S. Patent Nos. 7,119,145

© 2017 Phenomenex, Inc. All rights reserved.

Typical Loading Capacities

FL49380117_W

Vr

2√N

=Vi =

Loading...

Loading...