during recording. The dye based RW recordable

layer provides a reflectivity of 40% light return

and 70% light return. 40 percent reflectivity rep-

resents Pits and the 70% represent the Lands.

Record Process

The record process shares most of its mechani-

cal operation with that of the play process. The

main difference is how the Servo is locked to the

disc. The Servo follows the Pre-groove for Radial

Tracking and disc speed. The speed of the disc

is locked to a wobble signal that is part of the

spiral grove stamped into the disc.

The intensity of the laser beam is modulated

from playback intensity to write intensity. As the

disc reads the Pre-groove, the laser arrives at a

position where a Pit is to be formed. The laser

power increases from 4mW to 11mW. This raises

the temperature of the disc to 250 degrees

Celsius. The recordable layer melts, reducing its

volume. The polycarbonate flows into the space

vacated by the dye. The modulation from read

laser power to write laser power forms a pit and

land pattern effectively the same as a prerecord-

ed disc.

Re-recordable Technology

Disc Mechanical Layout

Disc usage mechanically is identical to the

recordable media. The only difference is the

chemical make up of the recordable layer. The

recordable layer is made up of an alloy of silver,

indium, antimony and tellurium.

Re-Recording Process

The Re-Record process shares much of its oper-

ation with that of a CDR. The blank disc’s

Information Area is in a polycrystalline state.

During recording, the laser power is modulated

from 8mW to 14mW. 8mW is the playback laser

power and 14mW is the record laser power. The

polycrystalline state of the recordable surface

changes, or melts at 500-700 degrees C into an

amorphous state. The melted, amorphous areas

reflect light less than the crystalline areas, creat-

ing a pattern similar to the stamped CD. A major

difference of CDRWs from CDRs is the ability to

erase.

The Erase Process

To Erase a CDRW disc, the recordable layer

must be returned to its polycrystalline state. This

is done by heating up the temperature of the

recorded surface to 200 degrees C. This is less

than the melting point. This is done at X2 record-

ing speed. The slower speed allows time for the

alloy to return to its proper state. This takes

approximately 37 min. Some software erases the

just the TOC on the disc and allows the disc to

be rewritten. This method is not as reliable

Over Writing Process

Overwriting combines the processes of erasing

and writing. When the disc and Light Pen are in

position to start writing the new data, the laser

power starts modulating in the same manner as

it does for normal recording with one difference.

During the time there is to be a land, the laser

power goes to the erase level rather than the

playback level.

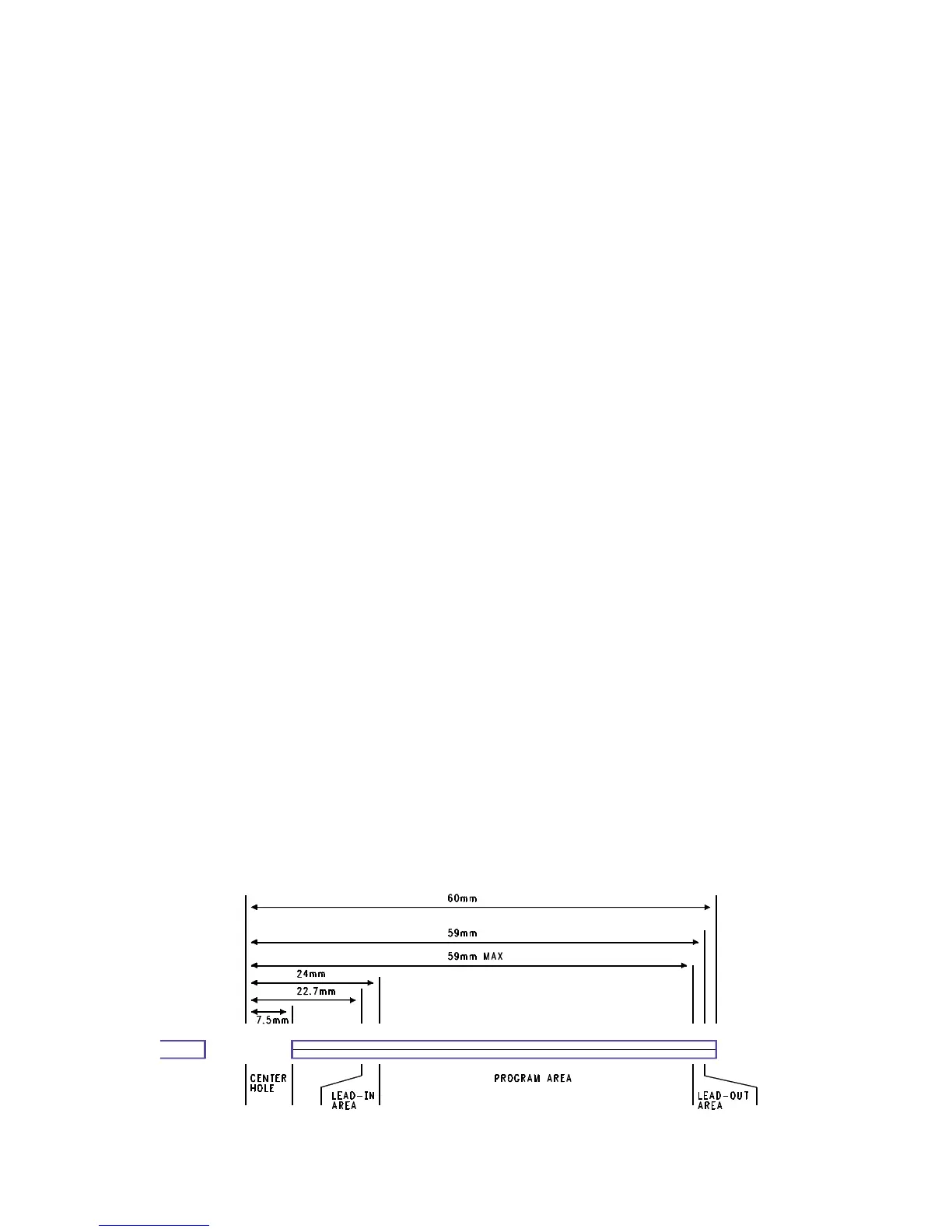

Figure 8 – Mechanical Layout of a DVD

5

Loading...

Loading...