CP600 Pivot Operators Manual

OPERATION, SAFETY & MAINTENANCE

Section 1-15

© Pierce Corporation

July 2010

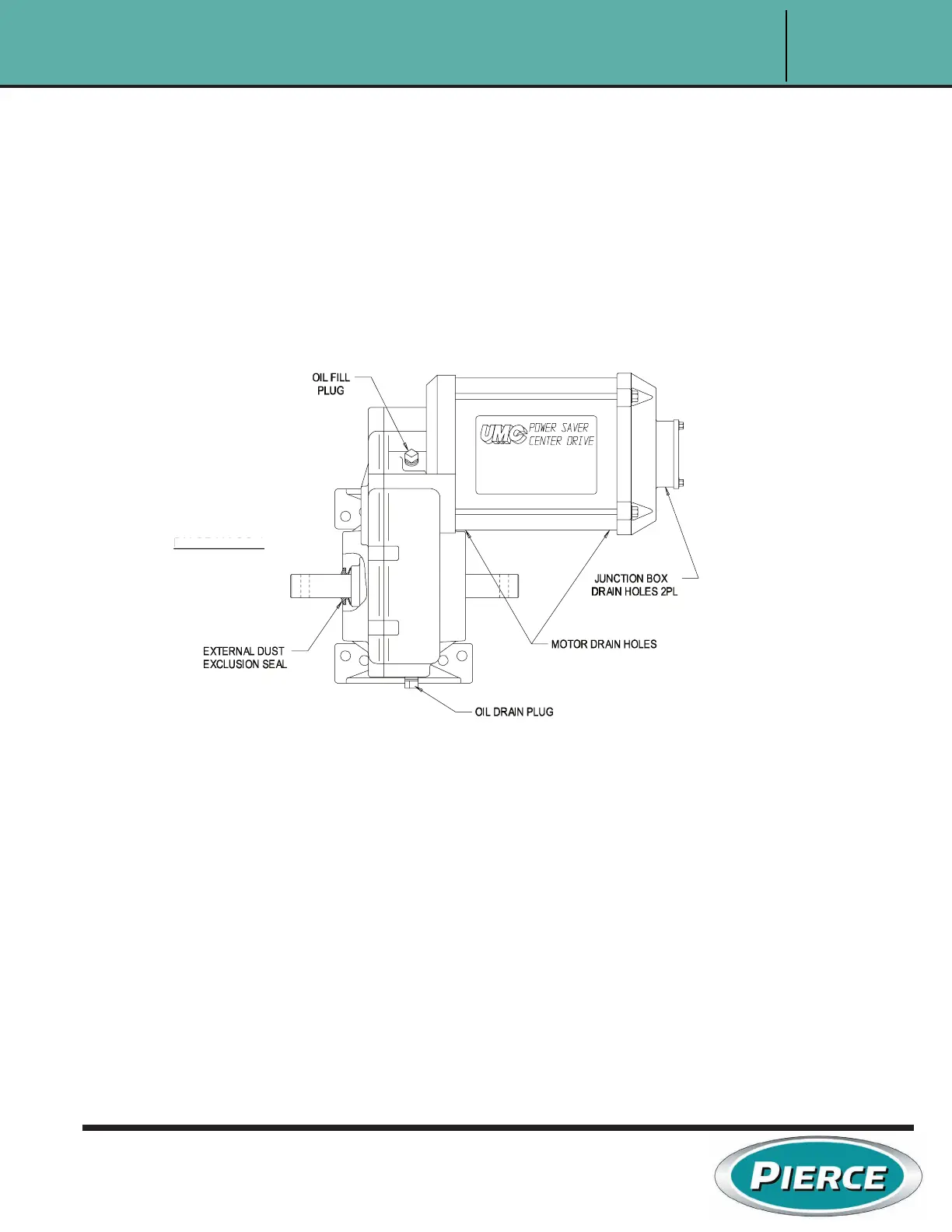

A. The Helical gear center drive must be serviced as follows after each crop cycle

(Minimum of once per year):

1. Inspect input and output seals for leakage. Should either of the seals show excessive

leakage, the seals should be replaced. All replaced seals must be installed with

generous amounts of #2 Barium/Lithium based grease or equivalent quality #2 water

resistant grease.

2. External seals should be used to keep dirt and water out of internal seal locations. If

the external seals are damaged or worn, replace with new seals.

3. The two (2) drain holes located under the motor can must be kept clear to allow

for drainage of accumulated moisture inside the motor if required. Do not pierce

or remove plug.

4. The two (2) drain holes located under the end bell must be kept clear to allow

drainage of accumulated moisture inside of the junction box.

5. Remove drain plug located at bottom of gearbox and completely drain gearbox.

If oil was contaminated or emulsifi ed, fl ush gearbox with a cup of specifi ed oil and

let drain completely.

6. Replace drain plug and refi ll to 1-1/2” (45 mm) from top of gear case as shown in

the drawing. Refer to gearbox oil specifi cations. After one or two hours the oil

should be re-checked. Air may be trapped in the gearbox during initial fi lling. Top

off with oil as needed.

Power Drivetrain Maintenance

Figure 1-13.

File: ams_srvc_0199.doc

Copyright 08/2004

II - SPUR GEAR CENTER DRIVE MAINTENANCE PROCEDURES

WARNING

� To reduce the potential of a severe electrical shock and to prevent bodily injury from sudden

startup of the motor, always disconnect all electrical power sources before initiating any

maintenance or repairs.

A. THE SPUR GEAR CENTER DRIVE MUST BE SERVICED AS FOLLOWS AFTER EACH CROP

CYCLE, A MINIMUM OF ONCE A YEAR.

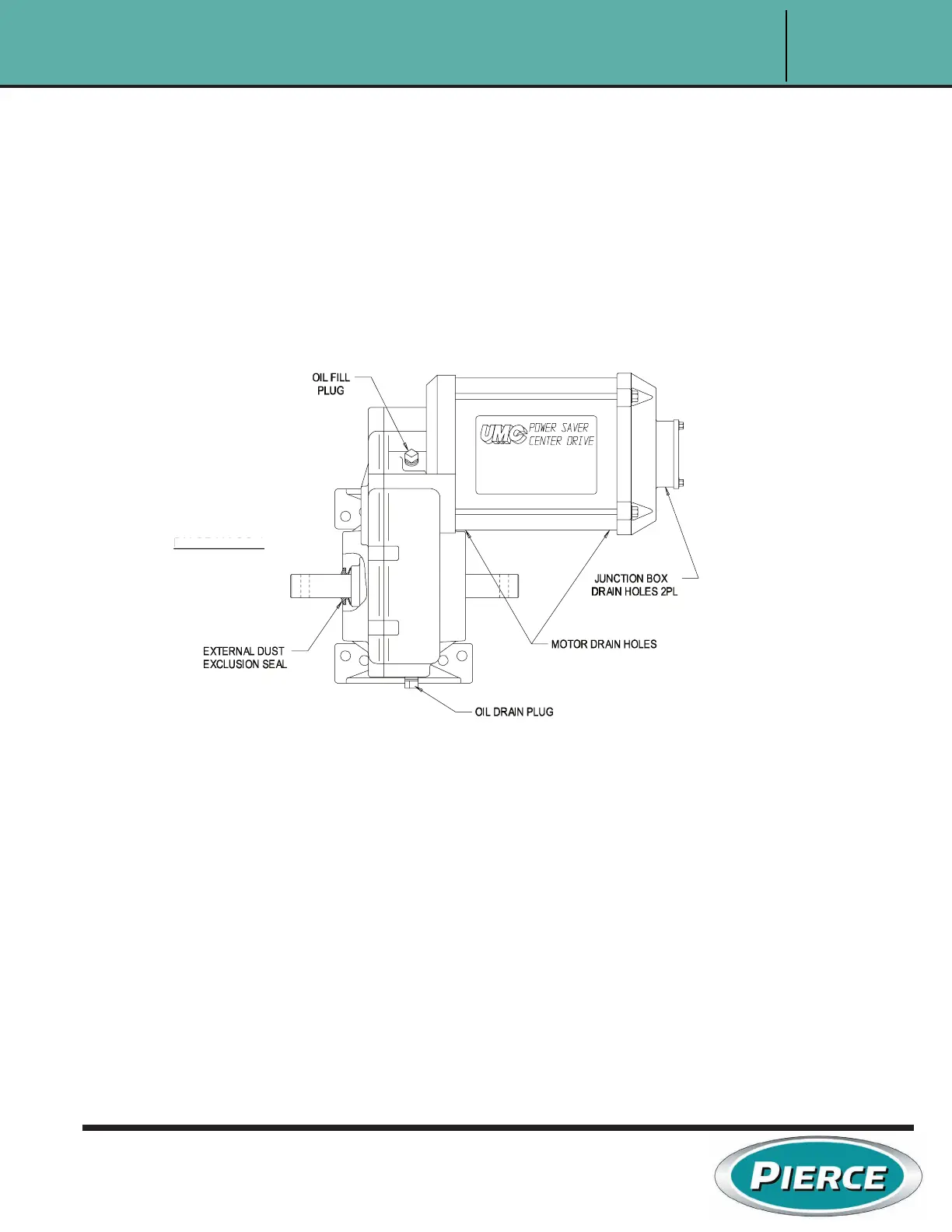

1. Inspect output oil seals for leakage. Should either of the seals show excessive leakage, the seals

should be replaced. All replaced seals must be installed with generous amounts of #2

Barium/Lithium base grease (or equivalent type #2 water resistant grease) on the seal lips.

2. External dust exclusion seals should be used to keep dirt and water out of internal seal locations.

If the external seals are damaged or worn, replace with new seals.

3. The two (2) drain holes located under the motor-can must be kept clear to allow for drainage of

accumulated moisture inside the motor. If any oil is found weeping out of the water drain holes,

remove the motor stator and inspect the rotor seal for leakage. Replace the seals same as step 1

above. DO NOT OPERATE THE UNIT WITHOUT INSPECTING THE ROTOR SEAL, A

SEVERE ELECTRIC SHORT MAY OCCUR IF THE PROBLEM IS NOT CORRECTED. Diagram

SG-1.

4. The two (2) drain holes located under the endbell must be kept clear to allow for drainage of

accumulated moisture inside of the junction box. Diagram SG-1.

DIAGRAM SG-1

5. Remove the drain plug located at bottom of the gearbox and completely drain the gearbox oil. If

the oil is contaminated or emulsified, flush the gearbox with a cup of specified oil and let it drain

completely.

Loading...

Loading...