CP600 Pivot Operators Manual

OPERATION, SAFETY & MAINTENANCE

Section 1-18

© Pierce Corporation

July 2010

Power Drivetrain Maintenance

B. Worm gear center drive gearbox lubricants:

A GL-5 SAE 140 or MIL C-2105 gear lube must be in worm gear center drive gear-

boxes. Some common brands meeting this specifi cation are listed in section B of Final

Drive Gearbox. Oil capacity is 3 ½ U.S. pints (1.6 Liters) approximately.

C. In-season worm gear center drive maintenance:

1. Proper oil level (mid bull gear) should be maintained at all times.

2. Contaminated or emulsifi ed oil should be replaced with fresh oil.

3. Input and output shaft seals should be inspected for excessive leaks and should

be replaced if necessary.

A. Driveline Coupler Maintenance

1. Drive line couplers should be inspected periodically for loose bolts and worn rub

ber inserts. Worn inserts should be replaced.

Power Drivetrain Maintenance

File: ams_srvc_0199.doc

Copyright 08/2004

III - WORM GEAR CENTER DRIVE MAINTENANCE PROCEDURES

A. THE WORM GEAR CENTER DRIVE MUST BE SERVICED AS FOLLOWS AFTER EACH

CROP CYCLE. MINIMUM ONCE A YEAR.

1. Inspect input and output shaft seals for leakage. Should either the input or output shaft seals show

excessive leakage, the seals should be replaced. All replaced seals must be installed with

generous amounts of #2 Barium/Lithium base grease (or equivalent quality #2 water resistant

grease) on the seal lips.

2. External seal protectors should be used to keep dirt and water out of internal seal locations. If the

external seals are damaged or worn, replace with new seals.

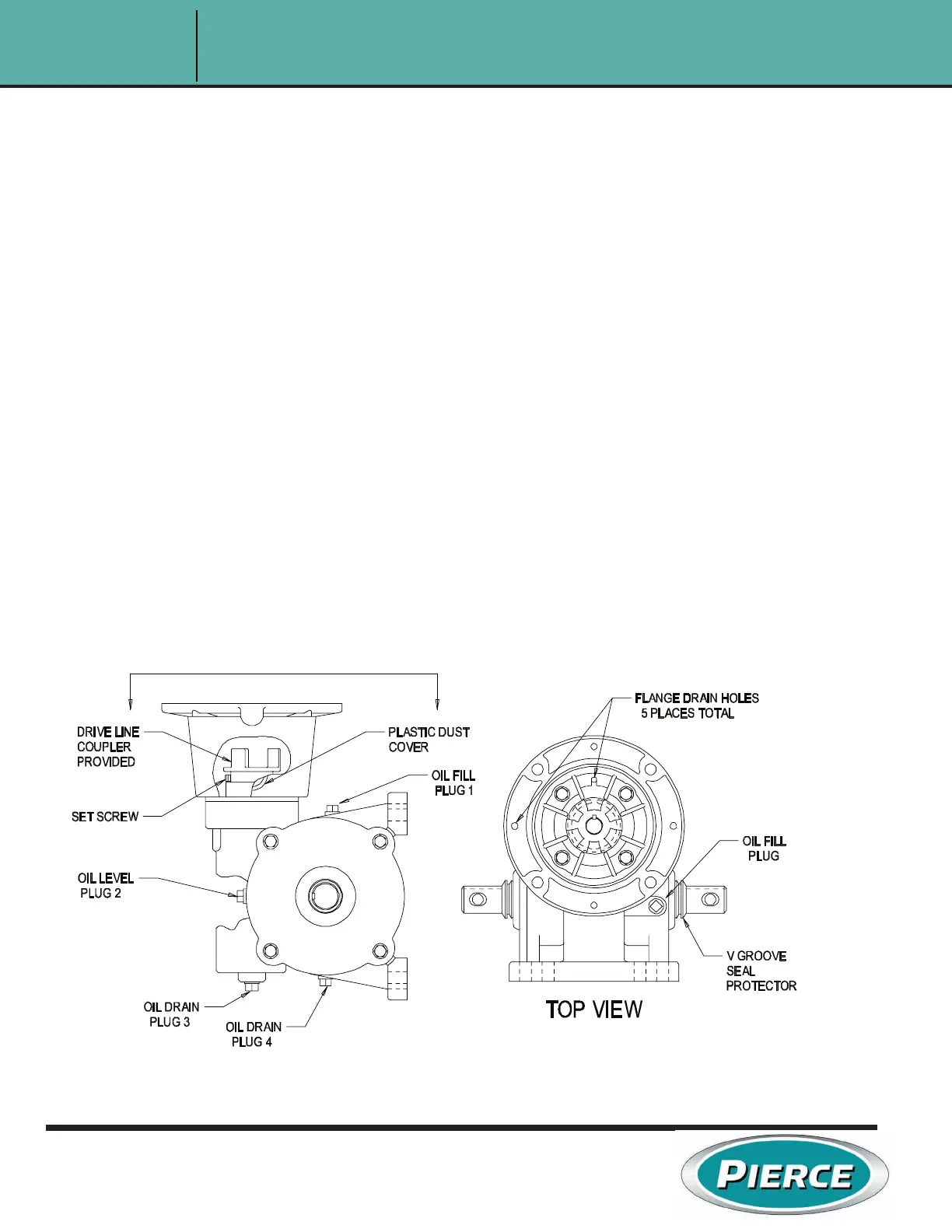

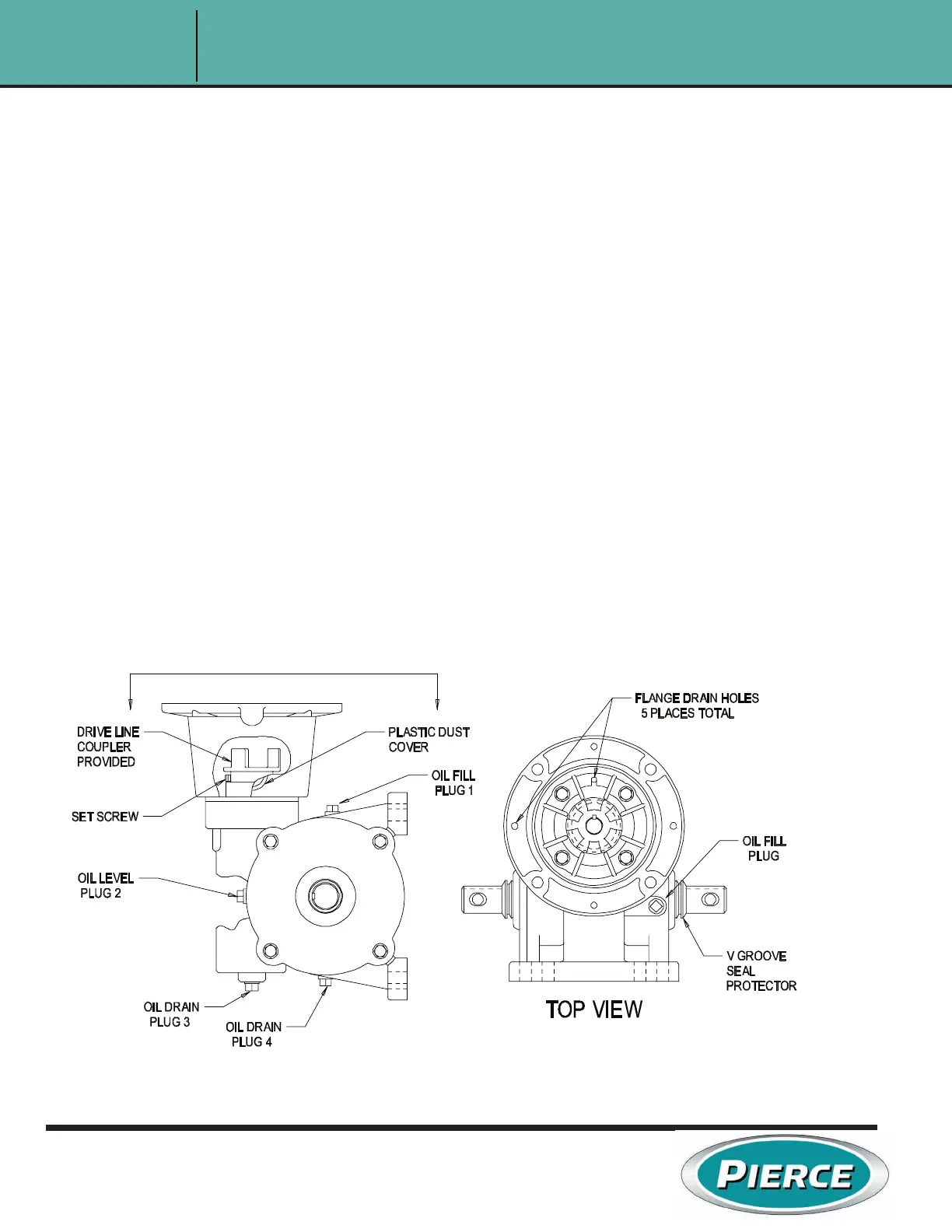

3. The flange drain holes (5 places) located under the motor mount flange must be clear. Clear the

hole with a 12-gauge wire, nail or punch by rotating in the hole to loosen and remove dirt. See

Diagram WG-1.

DIAGRAM WG-1

4. All 5/16-18 cover bolts and internal flange bolts should be torqued to 13-15 ft-lbs.

5. Remove the drain plugs located at bottom of worm (#3) and on the bottom of housing (#4) and

drain the gearbox oil. If the oil is contaminated or emulsified, flush gearbox with a cup of specified

oil and let it drain completely. See Diagram WG-1.

6. Replace the drain plugs and refill the gearbox with oil (at 70

�F ambient temperature) through the

oil fill hole (#1) to the proper operating level (mid worm gear at plug #2) as shown in Diagram

WG-1. Refer to the oil specification.

Figure 1-16.

Loading...

Loading...