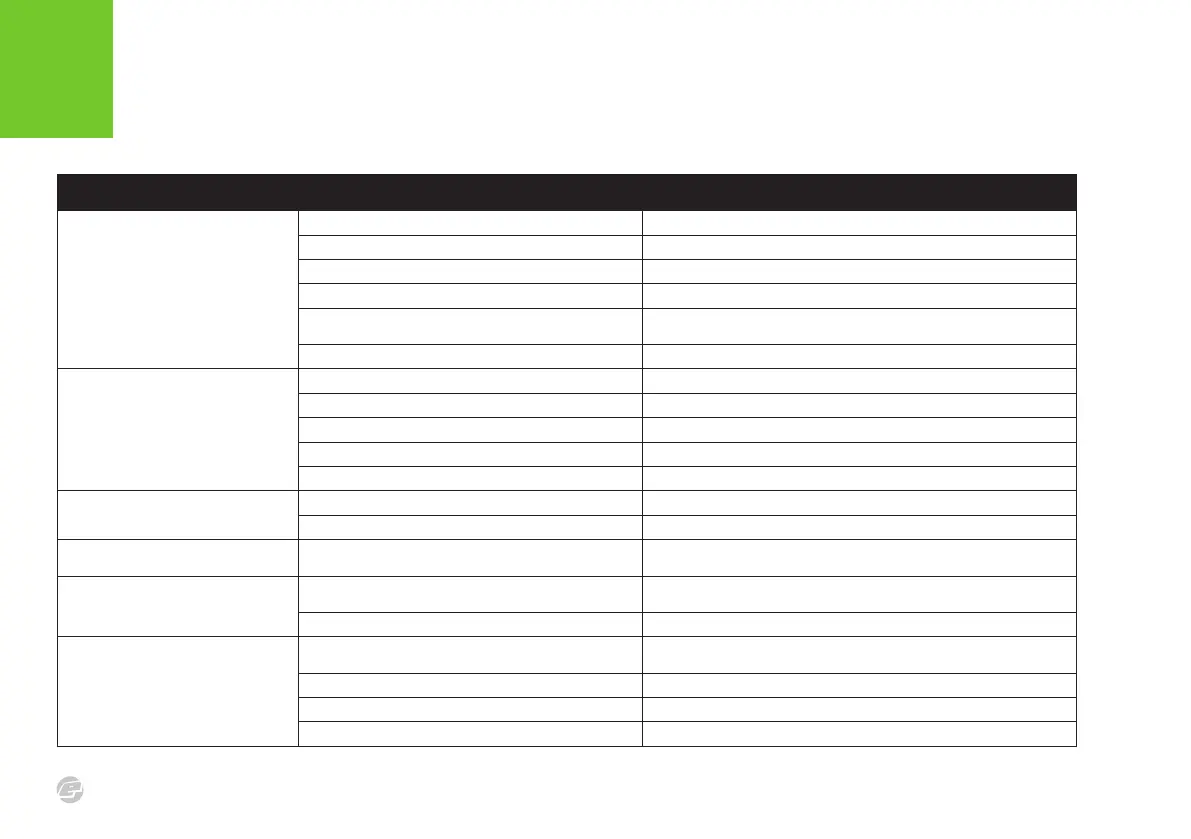

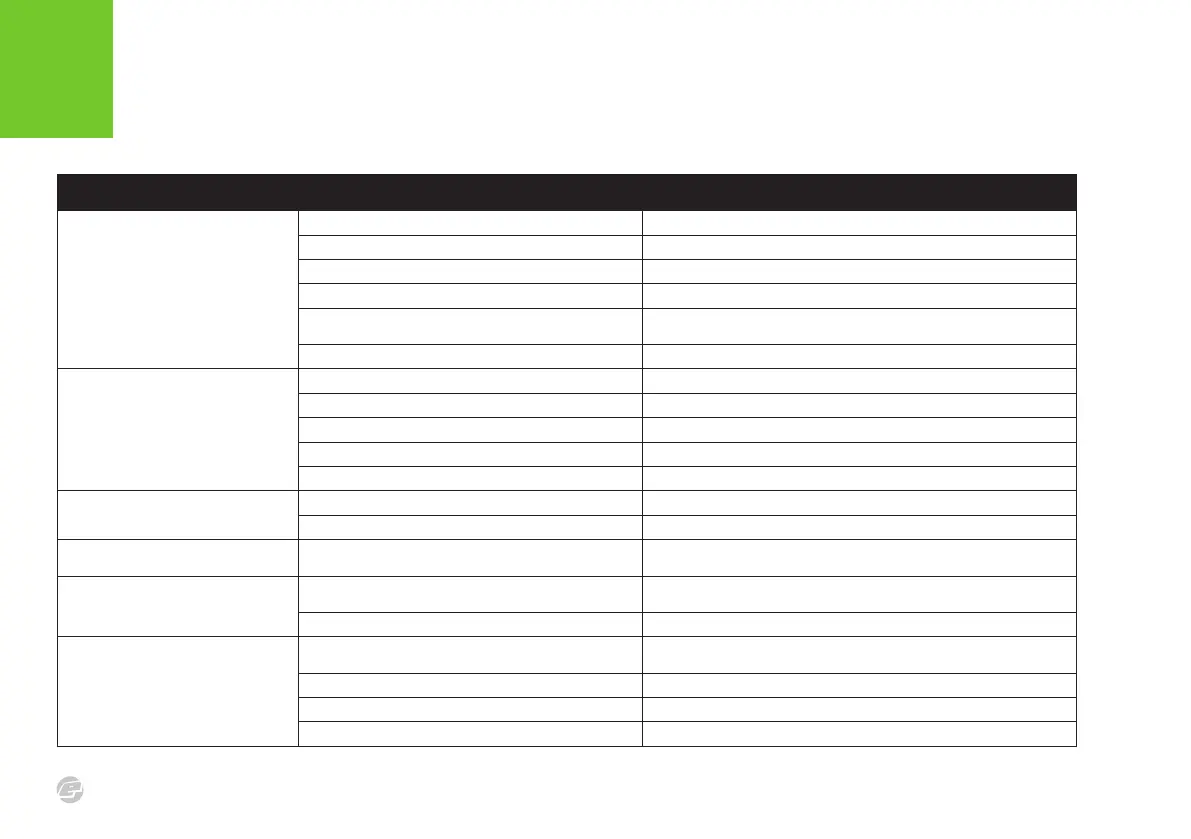

MAINTENANCE

FA ULT FI NDIN G TAB LES

C S 3

28

SYMP TOM POS SIBLE CAUS E SOLUT ION

The CS3 does not cycle fully.

The bolt assembly is dirty or incorrectly lubricated. Clean, re-lubricate and replace the o-rings on the bolt as necessary.

The DWELL parameter is set too low. Increase the DWELL parameter.

A sticky or faulty solenoid spool in the solenoid body. Check the spool, clean and replace seals as necessary.

There is a fault with the solenoid pilot. Replace the solenoid pilot.

The battery power is low or the batteries are

of a poor quality.

Replace the batteries. Use alkaline or lithium batteries.

Always use high quality batteries.

The paintballs are too tight in the barrel. Use a better paintball to barrel bore size match.

The CS3 is inconsistent.

The DWELL parameter is set too low. Increase the DWELL parameter.

Using poor quality paintballs. Use better quality paintballs.

A poor paintball to barrel bore match. Use a better paintball to barrel bore size match.

The inline regulator requires servicing. Strip and clean inline regulator. Replace o-rings and regulator seal.

Poor / inconsistent air supply to the POPS. Use a good quality preset air system.

The CS3 is inefcient.

Poor main spool performance. Clean and grease rear main spool seals. Check condition of spool spring.

A poor paintball to barrel bore match. Use a better paintball to barrel bore size match.

Rate of re is low and can’t be altered. Issues with the loader.

Try a different loader. Replace loader batteries.

Check force and sensitivity settings.

The CS3 has low velocity on the

rst shot.

The FSDO parameters are set too low to overcome

o-ring stiction.

Adjust FSD COMP and FSD DLY parameters.

The bolt assembly is dirty or incorrectly lubricated. Clean, re-lubricate and replace the o-rings on the bolt as necessary.

CS3 has velocity drop-off during

rapid re.

The batteries are poor quality or have insufcient charge.

Replace the batteries. Use alkaline or lithium batteries.

Always use high quality batteries.

Air system/regulator doesn’t ow fast enough to keep up. Use a good quality preset air system.

The bolt assembly is dirty or incorrectly lubricated. Clean, re-lubricate and replace the o-rings on the bolt as necessary.

Poorly maintained inline regulator. Strip, lubricate and rebuild the inline regulator. Replace Regulator Seal.

Loading...

Loading...