11

8.6 WORK

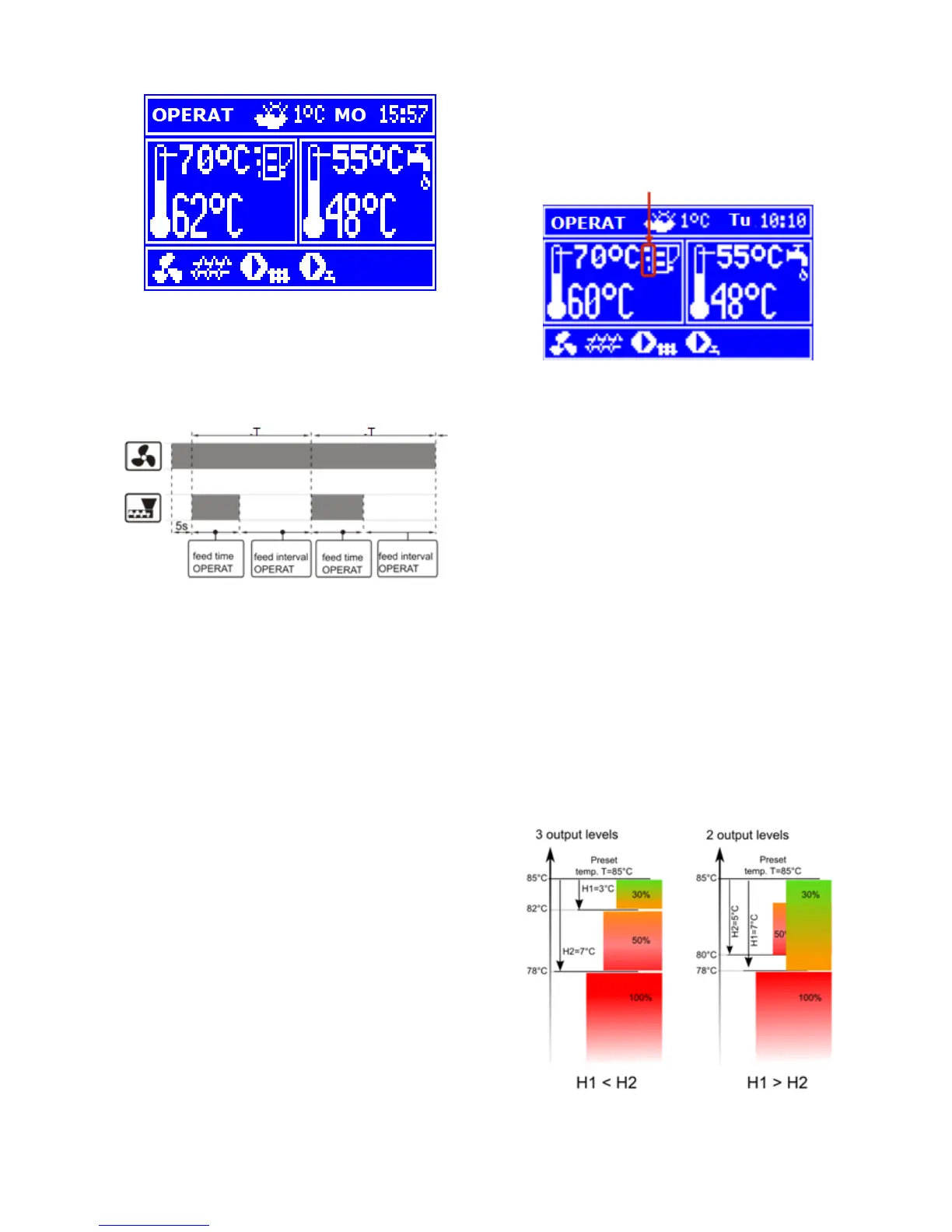

Pic. 5 Main window view while operating.

The fan operates constantly – see Pic. 6. Fuel

feeder is engaged periodically. One period

consists of feeder operating time and pause

in feeding time.

Pic. 6 . Fan and feeder operation periods.

Parameters related to Operation mode are :

feeder operating time and Air flush intensity

located in:

Menu → Boiler settings → Output

modulation

and operation time period located in

Menu → Service settings → Boiler settings.

There are two regulation modes responsible

for stabilization of boiler preset temperature:

Menu → Boiler settings → Regulation

mode

Standard mode operation

If the boiler’s temperature reach preset one

then the controller switches of to

SUPERVISION mode.

Controller is equipped with boiler’s power

modulation mechanism – which allows for

gradual power reduction when approaching

the preset temperature.

There are three power levels:

Maximal power 100%

Medium power 50%

Minimum power 30%

Current power level is displayed on the

screen as 3 segmented indicato rat the left

side of boiler’s icon.

Pic. 7. Power level indicator in main window.

Each level can be allocated with seperate fuel

feeding times and Air flush intensity which

influence on actual boiler’s power level.

Power levels parameters are available in the

menu:

Menu → Boiler settings → Output

modulation

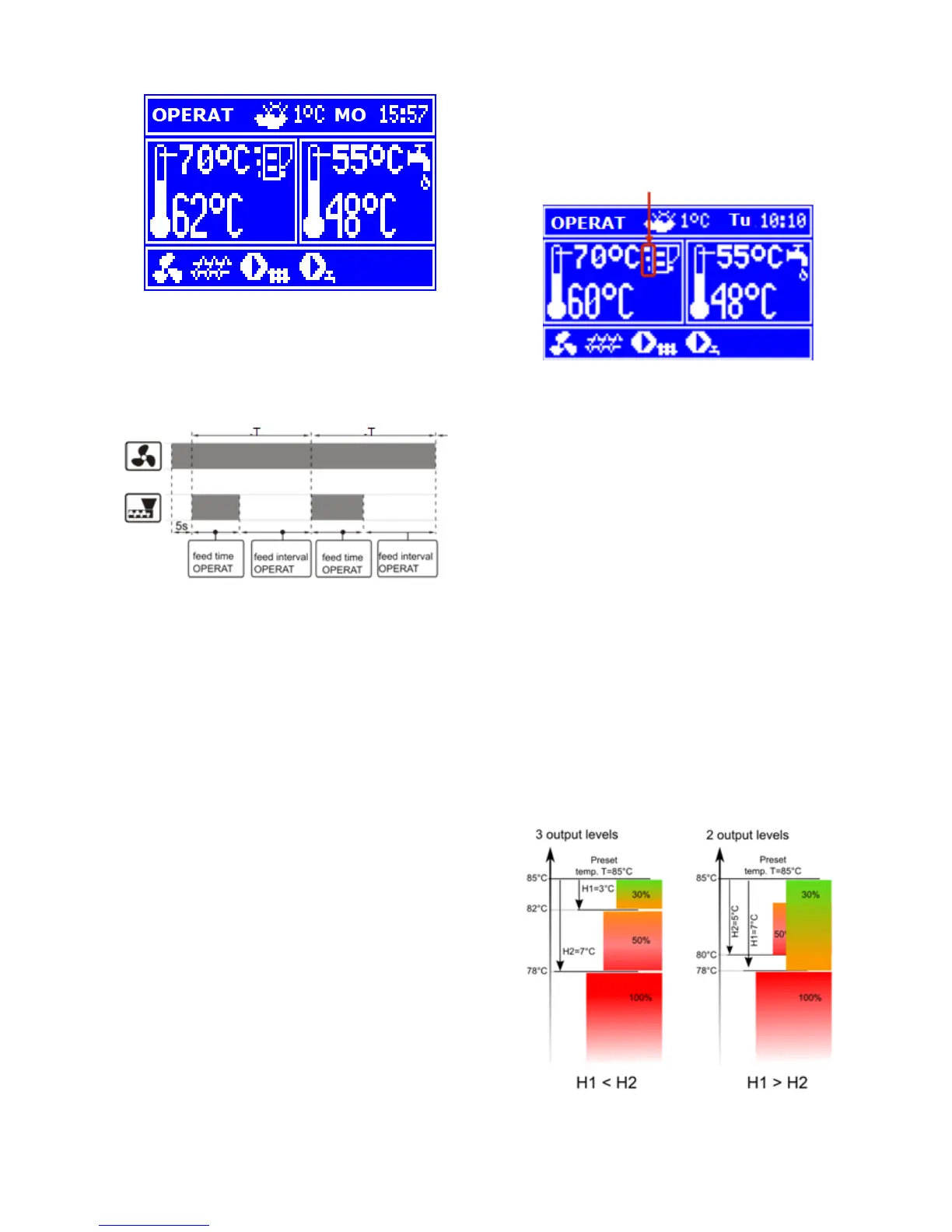

The controller regulates burner’s power with

which it operates depending on preset

temperature and defined hysteresis

Hysteresis H2 and Hysteresis H1 Pic. 8

Hystereses H1 and H2

It is possible to configure volumes H1 and H2

in such a way that modulation is done

without intermediate position. That means

switching from 100% to 30% with omission

of 50% power (right side of the picture).

Pic. 8 Hystereses H1 and H2 of power modulation

Loading...

Loading...