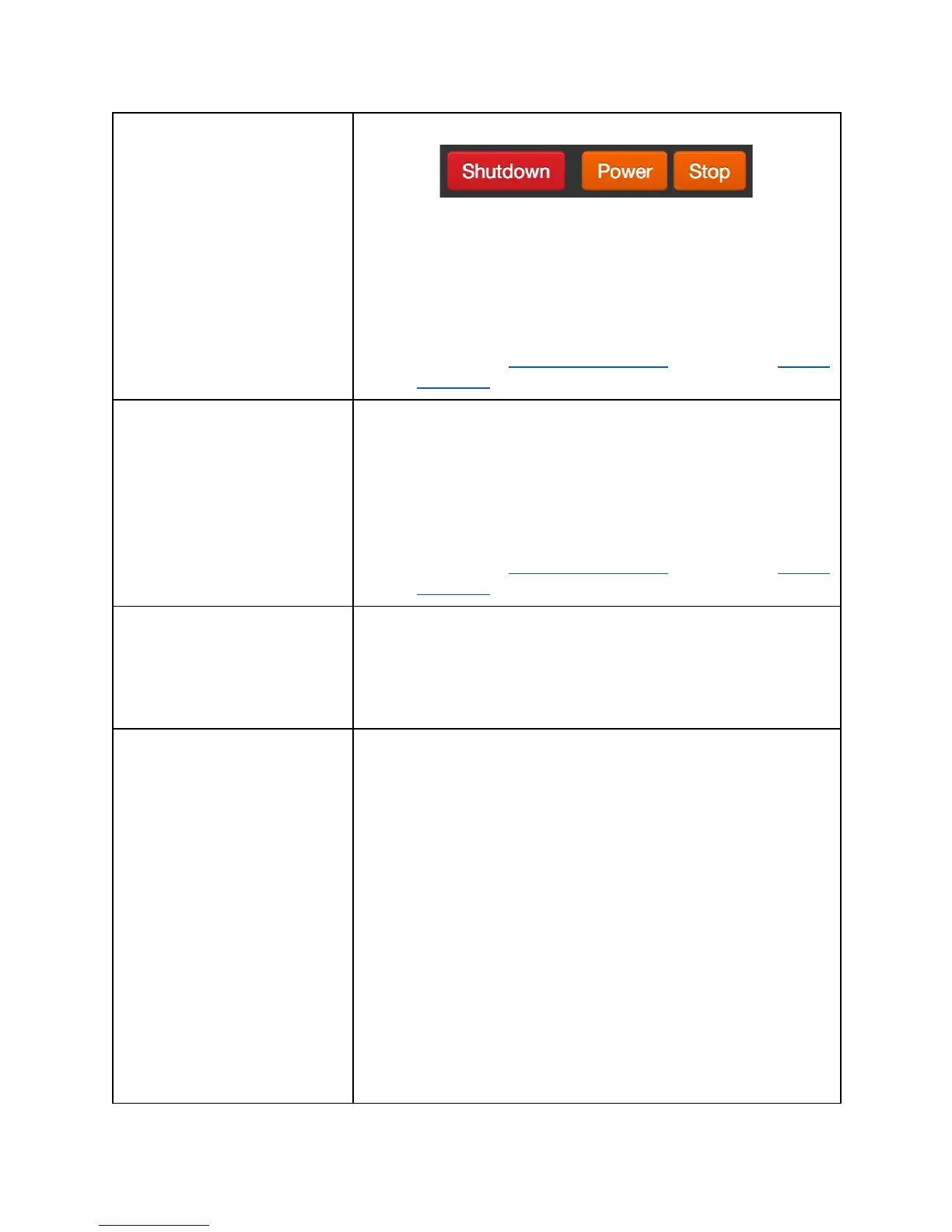

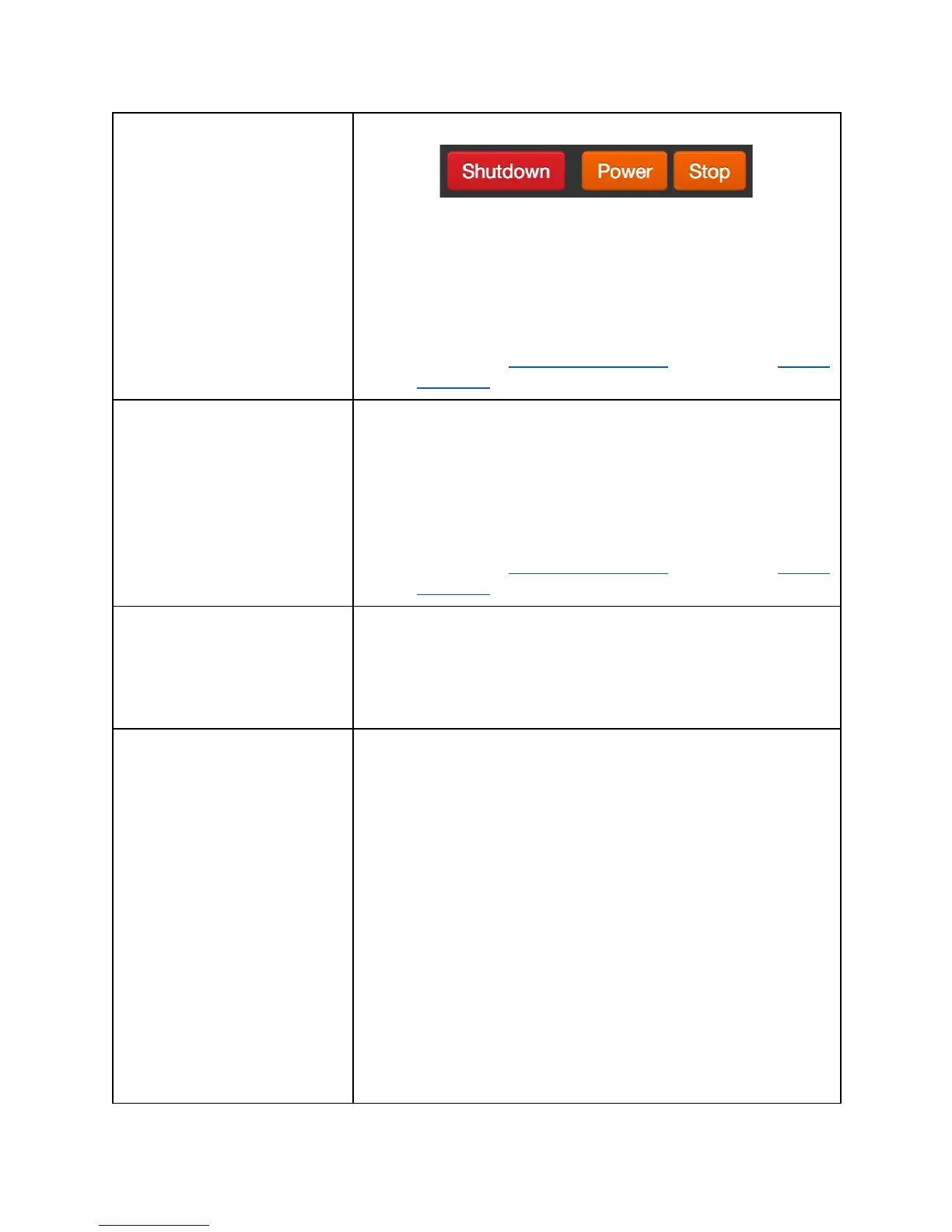

Push the E-stop button to enable the motors.

3. Check that the computer is still connected to the

Pocket NC with the USB cord.

4. Try rebooting the machine: power off the machine,

unplug all the cords, wait about a minute for the

capacitors to drain then plug it back in and restart.

5. Contact the Pocket NC help desk or post of the Pocket

NC forum for help.

One of the axes on my

Pocket NC is not working

1. Try rebooting the machine: power off the machine,

unplug all the cords, wait about a minute for the

capacitors to drain then plug it back in and restart.

2. Check the electrical connections for that axis. Look for

damage and debris.

3. Contact the Pocket NC help desk or post of the Pocket

NC forum for help.

The Pocket NC motors are

noisy when the machine is

running

Particularly at low feed rates, the stepper motors can produce

quite a bit of noise. This is due to the electrical interference in

the driver circuit.

Increasing the feed rate usually decreases the sound.

The Pocket NC is not cutting

in the location that I

expected.

1. Make sure that the origin for your toolpaths is the B

table offset/machine origin point of the Pocket NC.

This is a point in space about 0.839 inches above the

center of the B table.

2. Check if the coordinate system of your machining

setup in CAM is set up so that the positive Z axis

points at the spindle of the Pocket NC, the positive X

axis points at the A table, and the positive Y axis

points straight up from the B table.

3. Check if the toolpath origin is also the B table

offset/machine origin point and that the toolpath

coordinate system is appropriate. Remember that the

Z axis is always the Pocket NC spindle.

4. Make sure that your stock is located in the same place

Loading...

Loading...