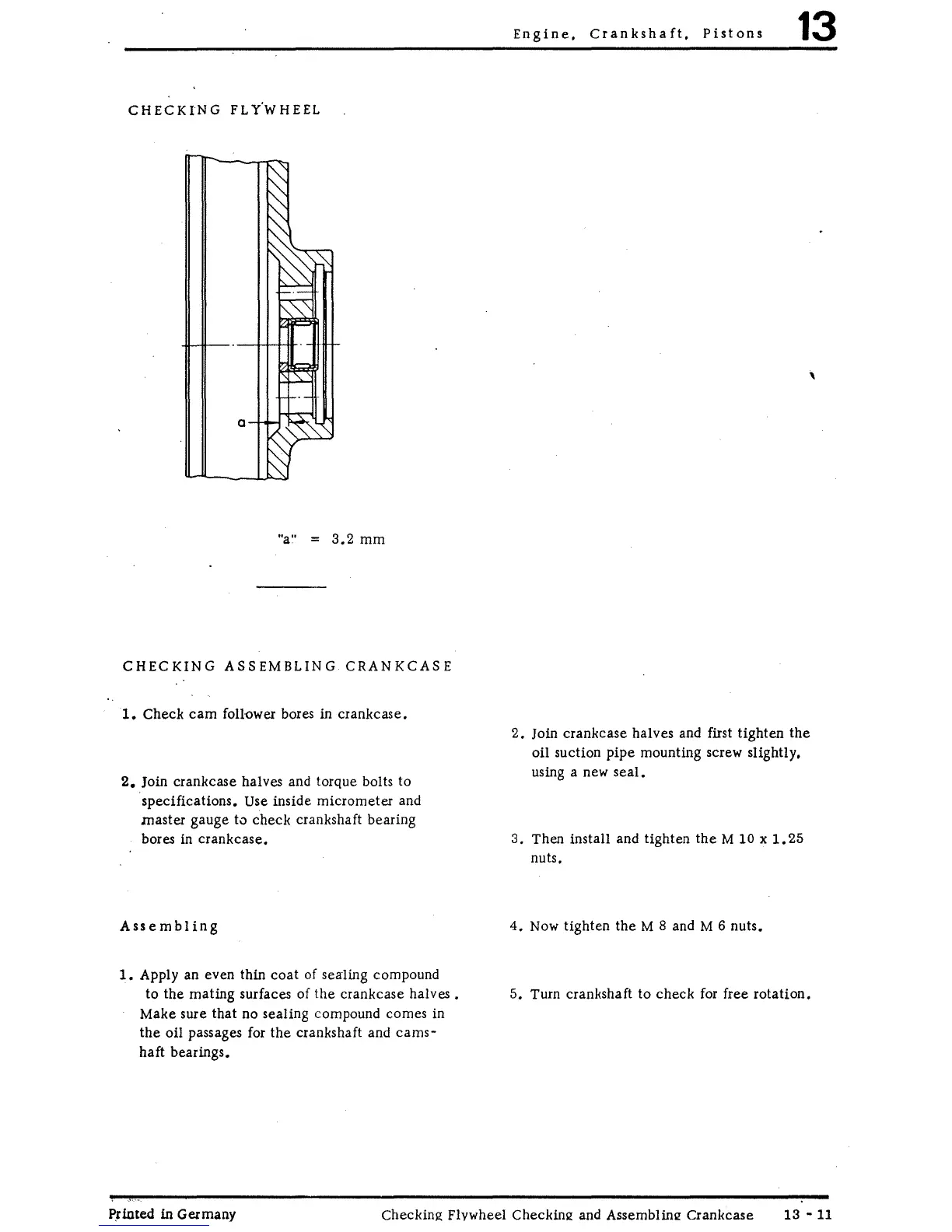

CHECKING

FL Y'WHEEL

"a~·

=

3.2

mm

CHECKING

ASSEMBLING

CRANKCASE

1.

Check

cam

foll{)wer bores in crankcase.

2.

Join crankcase halves and torque bolts to

·specifications.

Use inside micrometer and

master

gauge to check crankshaft bearing

bores in crankcase.

Assembling

1.

Apply an even thin

coat

of sealing compound

to

the mating surfaces of the crankcase halves •

Make sure that no sealing compound comes in

the

oil passages for the crankshaft and

cams-

haft bearings.

Engine,

Crankshaft,

Pistons

13

'

2.

Join crankcase halves and first tighten

the

oil suction pipe mounting screw slightly,

using a new

seal.

3.

Then install and tighten

the

M 10 x

1.

25

nuts.

4.

Now

tighten the M 8 and M 6 nuts.

5.

Turn crankshaft

to

check

for

free

rotation.

P_rinted

in Germany

Checking Flywheel Checking and

Assemblinl! Crankcase

13-

11

Loading...

Loading...