13.

Engine,

Crankshaft,

Pistons

CRANKSHAFT

END

PLAY

End

play

:

New

:

Wear

limit:

Adjusting

End

Play

0,07

-

0,13

mm

0,15

mm

1.

Install flywheel with two spacers, but.

without the seals

for

crankshaft and flywheel,

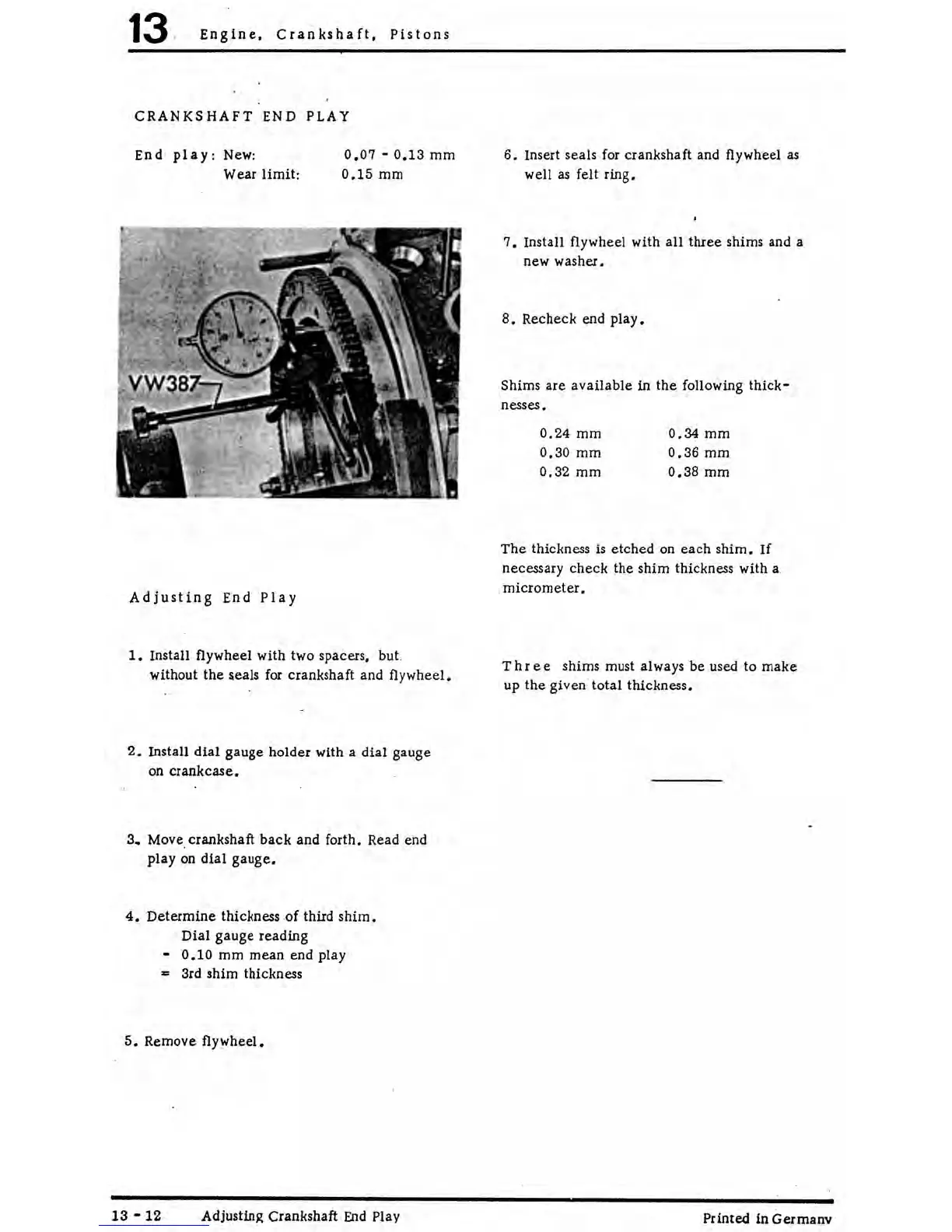

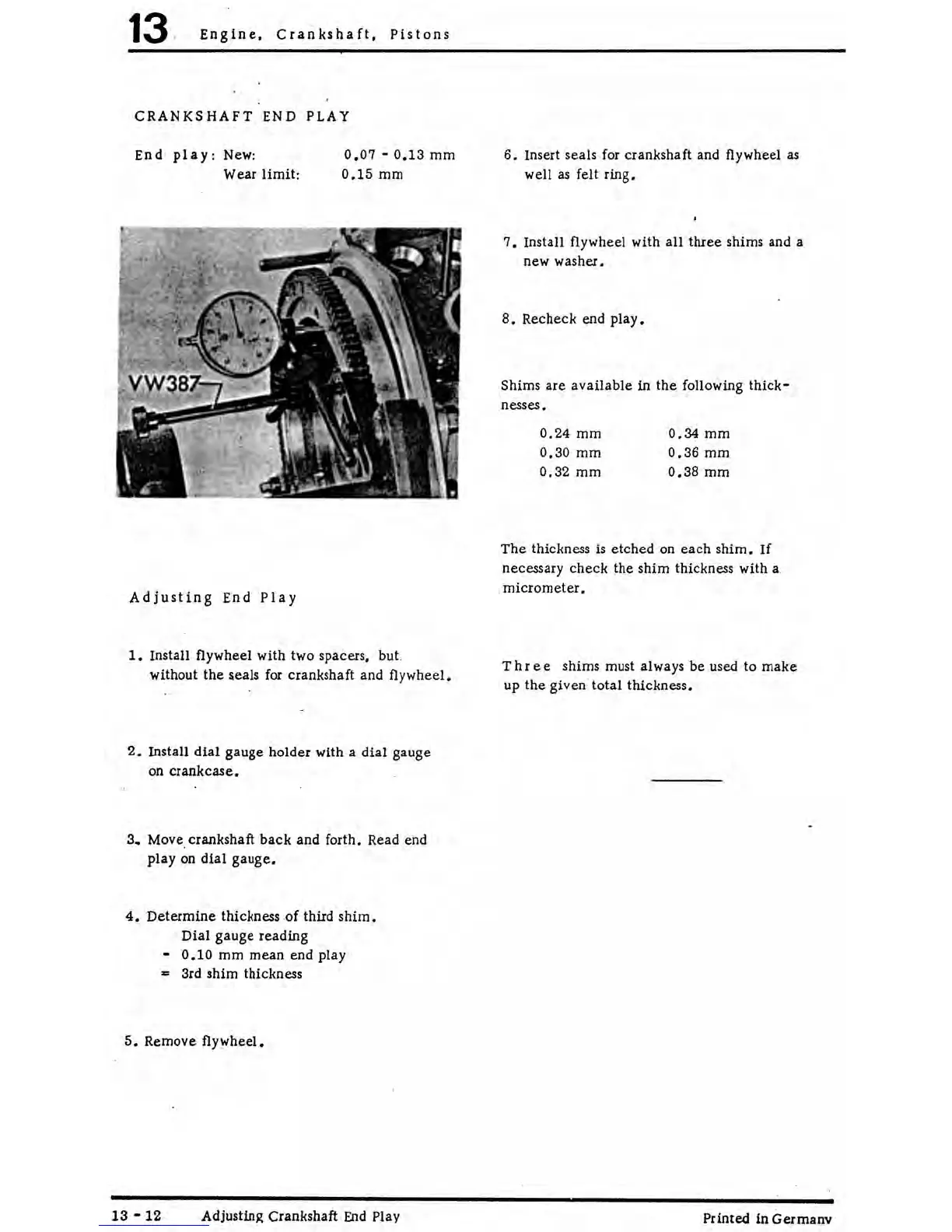

2.

Install

dial

gauge holder with a dial gauge

on crankcase.

3.,

Move. crankshaft back and forth, Read end

play

on

dial gauge.

4.

Determine thickness

of

third

shim.

· Dial gauge reading

-

0.10

mm mean end play

= 3rd shim thickness

5,

Remove flywheel.

13

-12

Adjustin9; Crankshaft

End

Play

6.

Insert seals for crankshaft and flywheel

as

well

as

felt ring.

7.

Install flywheel with

all

three shims and a

new washer.

8,

Recheck end

play.

Shims are

available

in

the

following

thick-

nesses.

0.24

mm

0,30

mm

0,32

mm

0.34

mm

0,36

mm

0.38

mm

The thickness

is

etched

on

each

shim.

If

necessary check the shim thickness with a.

micrometer.

Three

shims must always be used to

make

up the given total thickness • .

Printed

in Germanv

Loading...

Loading...