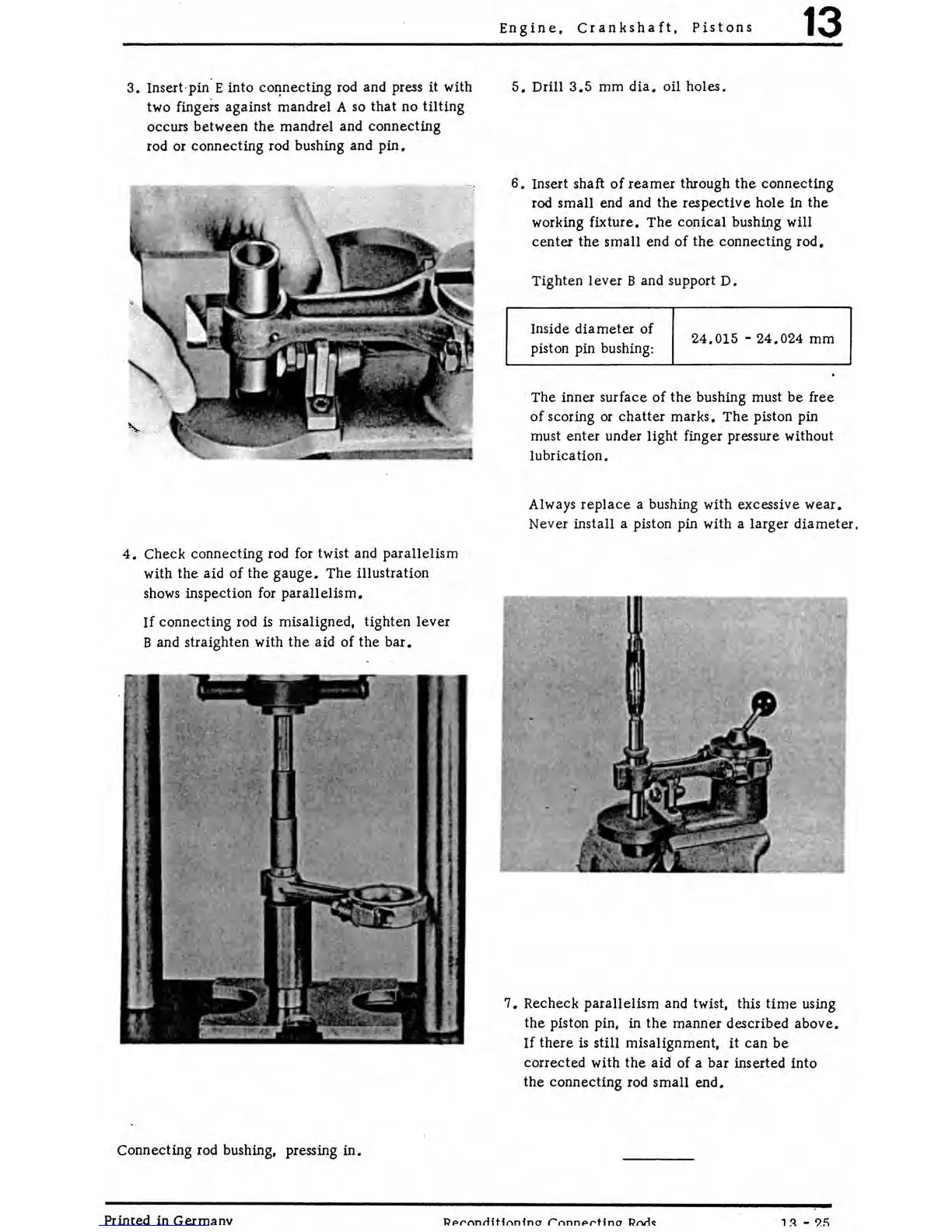

3.

Insert· pin· E into

co~necting

rod and press it with

two

fingers against mandrel A

so

that no

tilting

occurs between the mandrel and connecting

rod or connecting rod bushing and

pin.

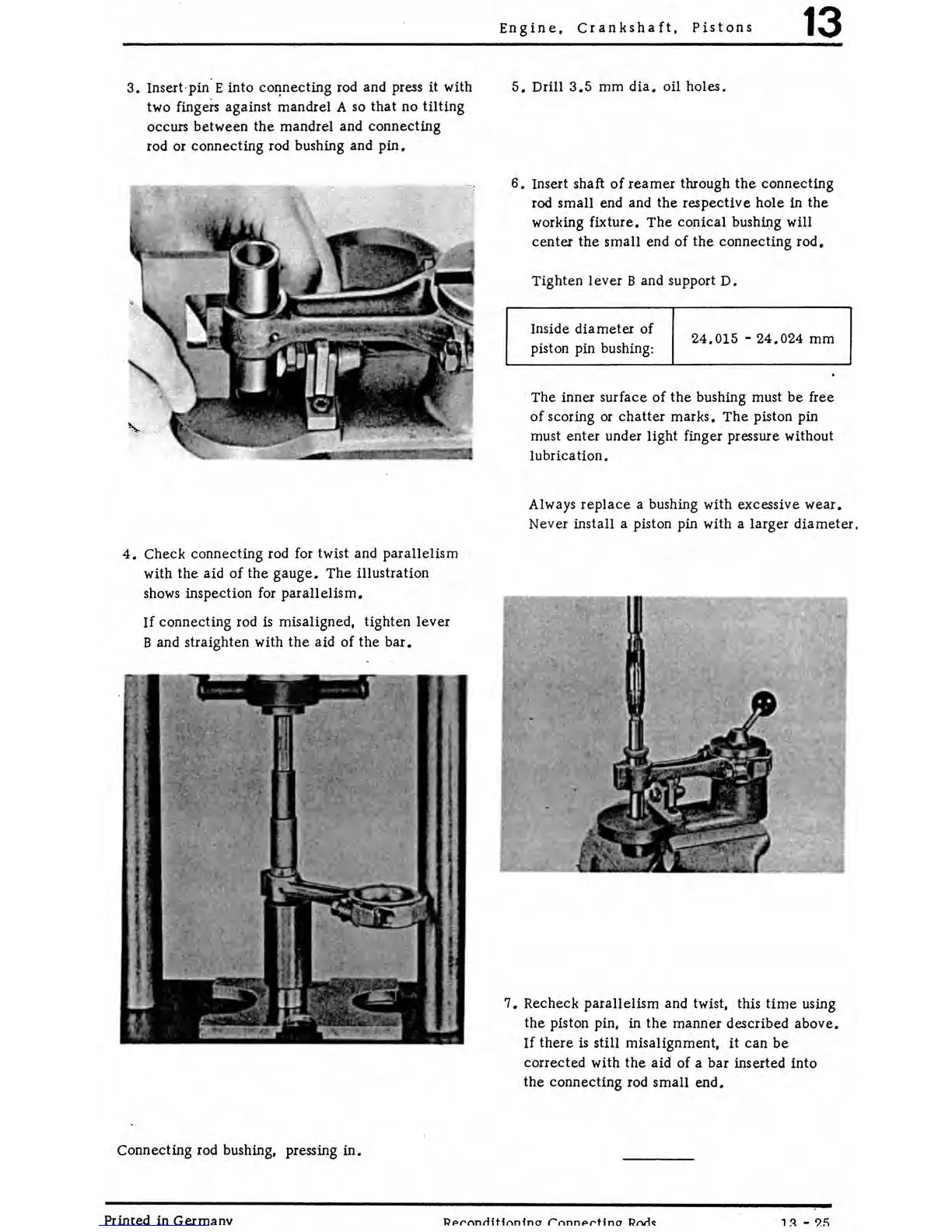

4.

Check connecting rod for twist and parallelism

with the aid

of

the

gauge.

The

illustration

shows inspection

for

parallelism.

If

connecting rod

is

misaligned, tighten

lever

B and straighten with

the

aid of the

bar.

Connecting rod bushing, pressing

in.

Engine,

Crankshaft,

Pistons

13

5.

Drill

3.5

mm

dia.

oil holes.

6.

Insert shaft

of

reamer

through

the

connecting

rod small end and the respective hole in the

working fixture.

The

conical

bushing will

center the

small

end of

the

connecting

rod.

Tighten lever

Band

support

D.

Inside

diameter

of

piston pin bushing:

24.015

-

24.024

mm

The inner surface

of

the

bushing must be free

of

scoring

or

chatter

marks.

The

piston pin

must enter under light finger pressure without

lubrication.

Always

replace

a bushing with excessive

wear.

Never install a piston pin with a larger

diameter.

7.

Recheck parallelism and twist, this

time

using

the piston pin, in the manner described above.

If

there

is

still misalignment,

it

can

be

corrected with

the

aid of a bar inserted into

the connecting rod small

end.

Printed in Germanv

RPf'l"lnrlitfrmfncr

rnnnPf'tfncr

Rnrlo

Loading...

Loading...