silicon carbide, but is tougher and more suited for woods and soft

(nonferrous) metals. Silicon carbide is extremely hard and is best suited for

surfacing stone, marble and glass.

Abrasives are classed as open-coated (grit spaced) or closed-coated

(Grit non-spaced). Closed coatings provide hard, fast cutting action for

hardwoods and dense metals while the open coatings are more suited to

soft materials and painted surfaces.

To obtain the best finish, start with a “COARSE” grade of abrasive and

change to “MEDIUM” and “FINE” grades as work progresses.

A wide range of available PORTER-CABLE Sanding Belts is listed in the

back of the manual. Keep a full assortment on hand so that the correct

belt will always be available.

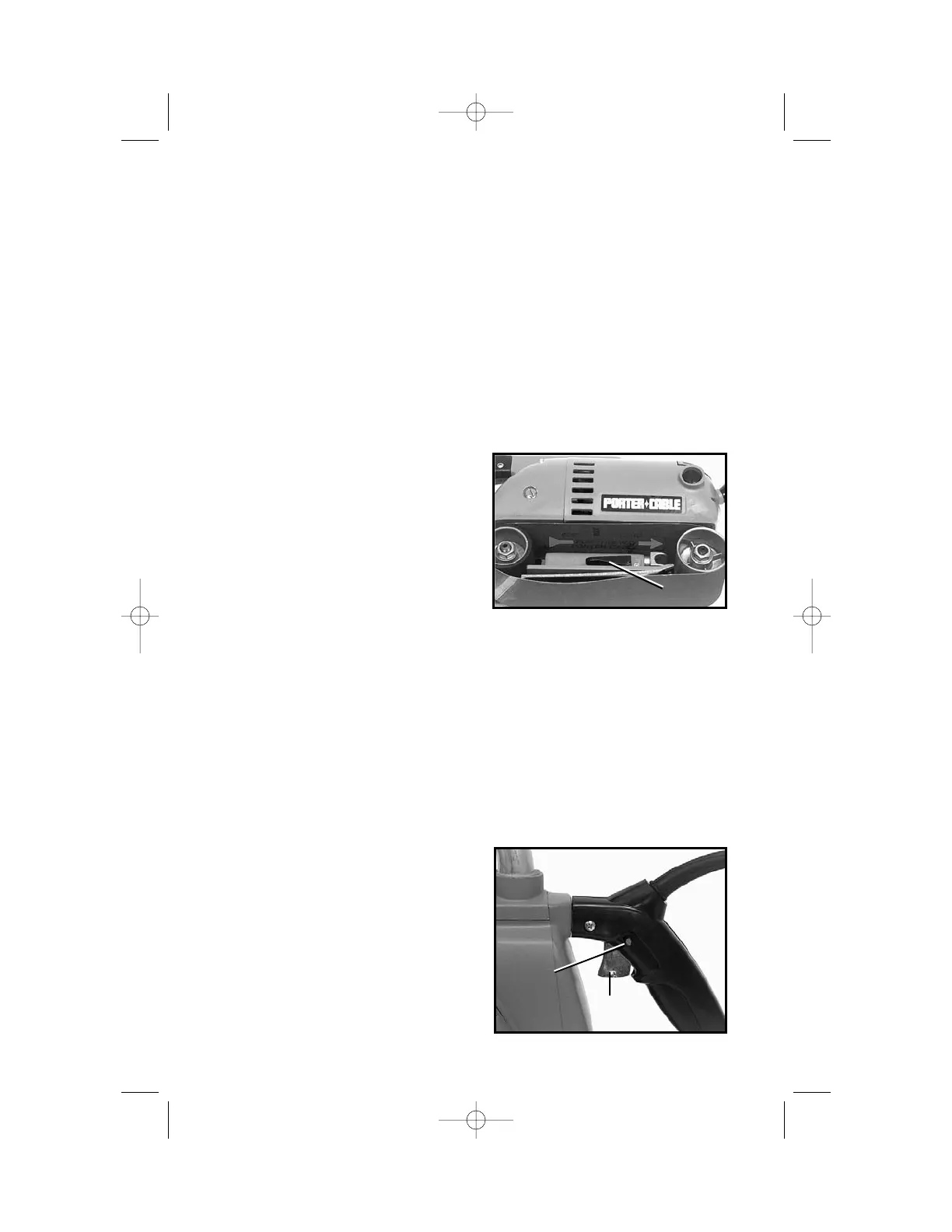

INSTALLING AND REMOVING THE ABRASIVE BELT

CAUTION: Disconnect tool from

power source.

1. Lay sander on its left side and

turn the tension relief lever (A) Fig. 1,

locking it under the catch on the

plate.

2. Remove the old belt.

3. Install new belt so that arrow,

printed on inside of belt, is at the top

and pointing toward the front of the sander.

NOTE: Some sanding belts are bi-directional. These bi-directional belts

will not have arrows printed on them. They may be installed to run in

either direction.

4. Position the belt so that the outer edge is flush with the outer ends of

the pulleys.

5. Release tension lever to restore belt tension.

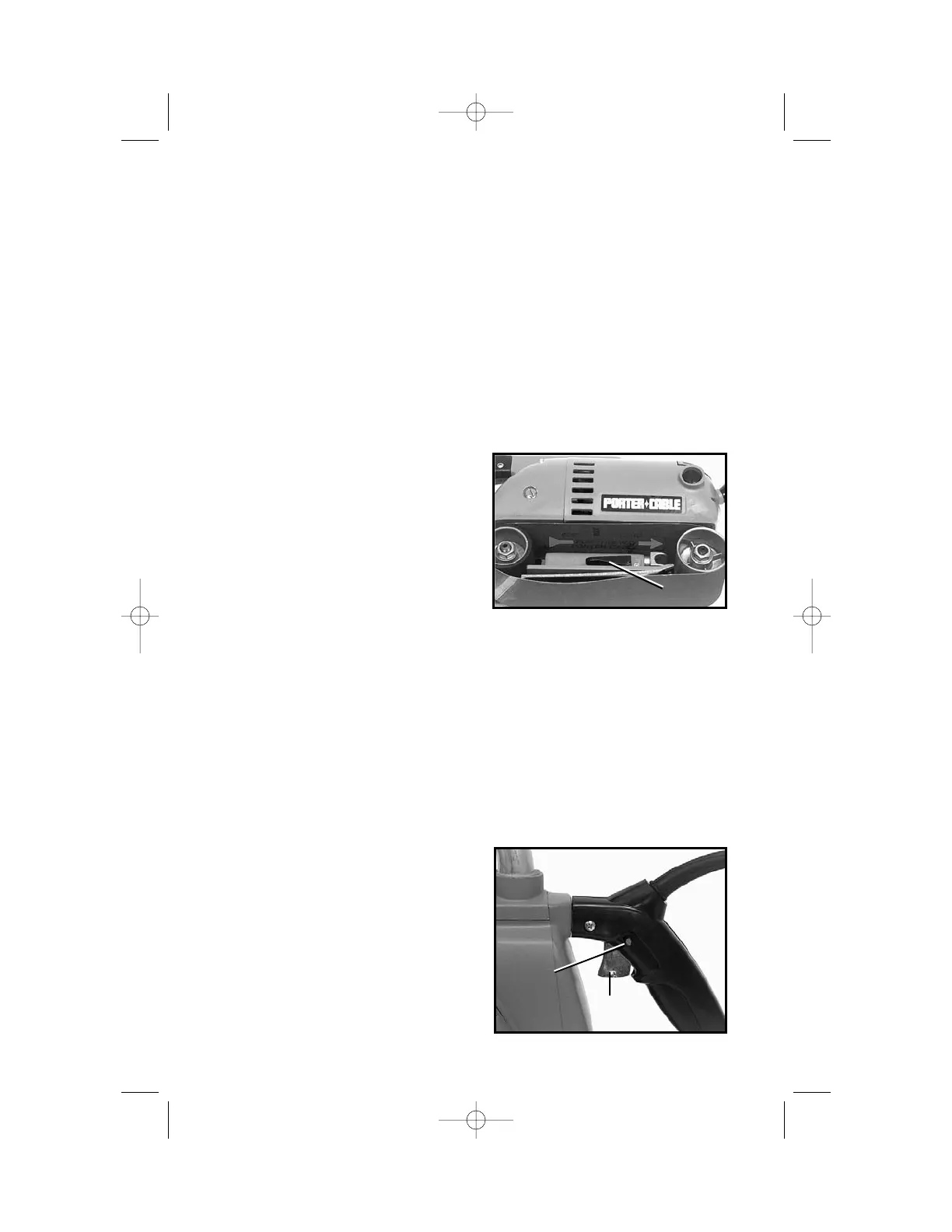

TO START AND STOP BELT SANDERS

CAUTION: Make sure switch is off

and power circuit voltage is the

same as the voltage shown on the

specification plate on the sander.

connect machine to power circuit.

1. Squeeze trigger switch (A) Fig. 2, to

start motor. Release trigger to stop

motor.

2. A lock button (B) Fig. 2 is

provided to keep motor running

continually without pressing the

trigger.

7

Fig. 1

A

Fig. 2

B

A

Loading...

Loading...