GB/IE

10

Comparison of plug and socket (see fig. C):

j

First measure the dimensions of the plug.

j

You may wish to make a note of the measurement.

j

Then measure the socket.

Deviation from a reference value (see fig. D):

j

Measure a reference object (in this case A).

j

Leave the measuring jaws

2

/

11

in this position

and press the key to obtain the zero setting (ZERO)

9

.

j

Then measure the second object.

The LCD display

5

now shows the deviation of the measure-

ment of the second object to that of the reference object (A).

Measuring the thickness of the floor of an object

(see fig. E):

j

First measure the depth of the object.

j

Leave the depth blade

6

in this position and press the key

to obtain the zero position (ZERO)

9

.

j

Now measure the entire object.

The LCD display

5

now shows the thickness of the floor of

the object.

Measuring the distance between two identical

holes (see fig. F):

j

First measure one of the two, equally sized holes.

j

Leave the measuring jaws

2

/

11

in this position and press

the key to obtain the zero position (ZERO)

9

.

j

Now measure the total dimension.

The LCD display

5

now shows the average distance.

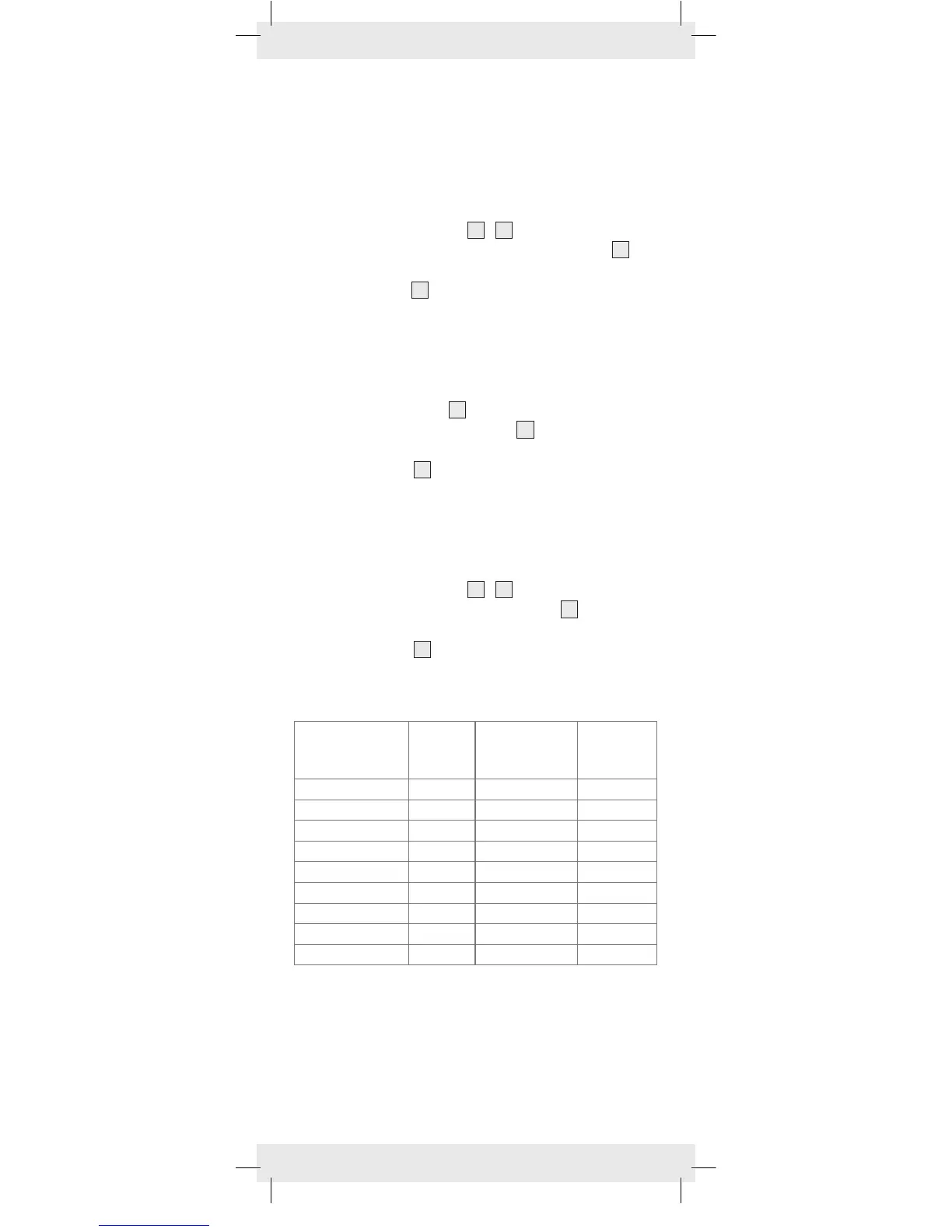

Characteristics of metric ISO screw threads:

Nominal diameter:

[mm]

Increase:

[mm

-1

]

Core diameter:

[mm]

Drill

diameter:

[mm]

3 0.5 2.46 2.5

4 0.7 3.24 3.3

5 0.8 4.13 4.2

6 1 4.92 5

8 1.25 6.65 6.8

10 1.5 8.38 8.5

12 1.75 10.11 10.2

16 2 13.84 14

20 2.5 17.29 17.5

Q

Troubleshooting

The device contains sensitive electronic components. That is why

it experiences interference when in close proximity to radio trans-

mission devices. If any indication errors appear in the display,

remove such devices out of the proximity of the calliper.

Loading...

Loading...