4

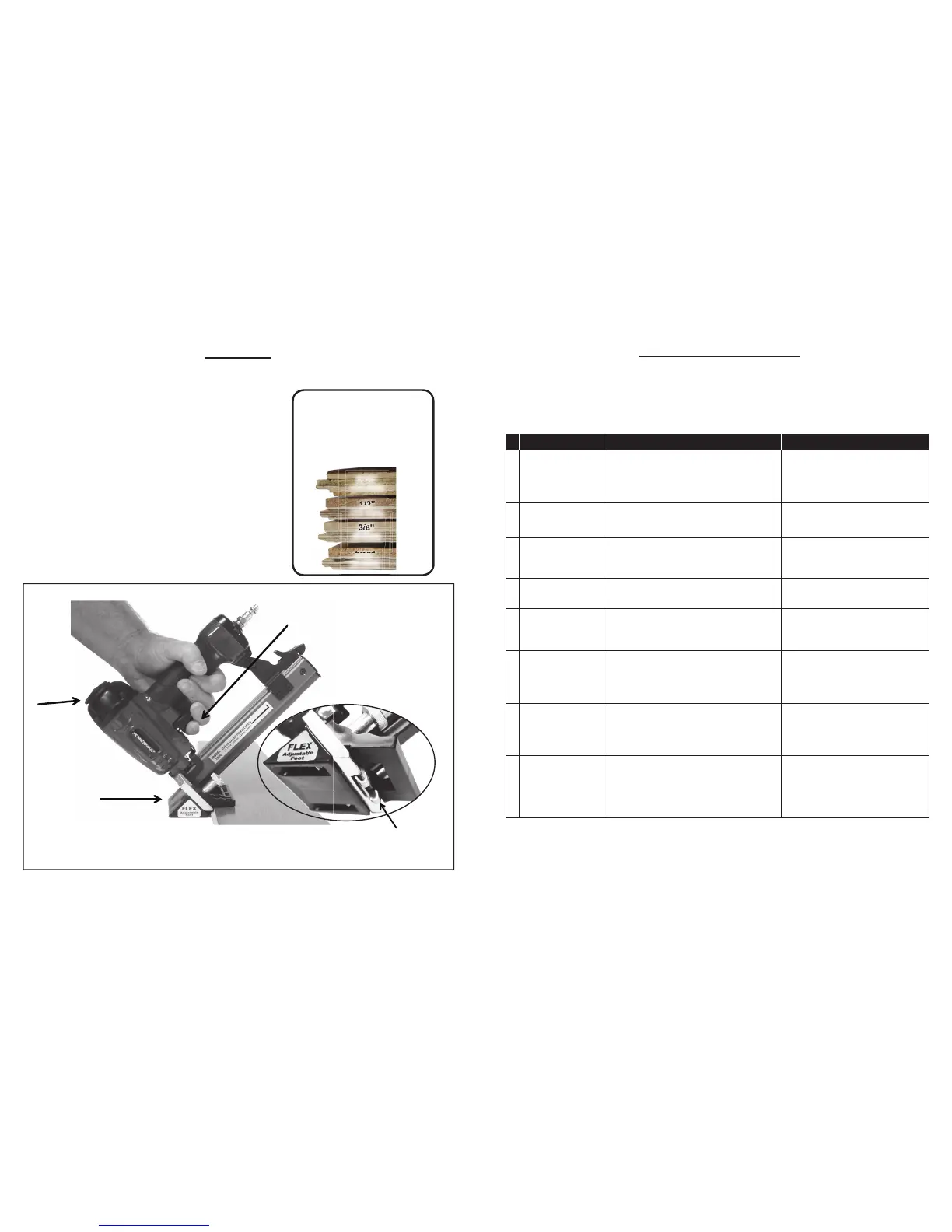

The Model 2000 nails down fl ooring from

5/16” to 9/16” using the Powernail FLEX

adjustable foot assembly that can be adjusted to

fi t different fl ooring profi les.

To use the Model 2000, simply snug up the

fl ooring, pull the trigger and let the nailer drive and

set the nail at the correct 45 degree angle.

The unique body design allows for different grip

angles and has an adjustable exhaust port to

redirect nailer exhaust.

OPERATION

The Model 2000

installs tongue and

groove fl ooring

from

5/16” to 9/16”

.

Adjustable

Exhaust

Port

Floor activated safety mechanism

prevents accidental tool activation.

Trigger-pull Operation!

Adjustable

FLEX Foot

Assembly

5/16"

(8 mm)

PROBLEM POSSIBLE CAUSE SOLUTION

1

Air leaking at

Trigger area

1. O-ring (31) in trigger valve is damaged.

2. Trigger valve head (30) is damaged.

3. Trigger valve stem (35), seal (29) or O-ring (31)

is damaged.

1. Check and replace O-ring.

2. Check and replace trigger

valve head.

3. Check and replace trigger valve stem,

seal or O-ring.

2

Air leaking between

body and drive guider

Damaged bumper (22). Check and replace bumper.

3

Air leaking between

body and cylinder cap

1. Screw loose (5).

2. Damaged gasket (8).

1. Tighten screws.

2. Check and replace gasket.

4

Blade driving

fastener

too deeply

1. Worn bumper (22).

2. Air pressure is too high

1. Replace bumper.

2. Adjust the air pressure.

5

Runs slowly or

has loss of power

1. Insuffi cient oil.

2. Insuffi cient air supply.

3. Broken spring in cylinder cap (8a).

4. Exhaust port (3) in cylinder cap is blocked

1. Lubricate as instructed

2. Check air supply.

3. Replace spring.

4. Replace damaged internal parts.

6

Tool skips a fastener

1. Worn bumper (22) or damaged spring (57).

2. Dirt in gate (50).

3. Inadequate airfl ow to tool.

4. Worn or dry O-ring (17) on piston.

5. Cylinder cap seal leaking (8).

1. Replace bumper or pusher spring.

2. Clean drive channel of front plate.

3. Check hose and compressor fi ttings.

4. Replace O-ring or lubricate.

5. Replace seal.

7

Fasteners are

jammed

(see page 8)

1. Joint guider is worn (24).

2. Fasteners are wrong size or damaged.

3. Magazine or front plate screws are loose (78).

4. Blade (27) in piston assembly is damaged.

1. Replace joint guider.

2. Use the recommended and

undamaged fasteners.

3. Tighten screws.

4. Replace piston assembly.

8

Tool will not drive

down tight

1. Worn blade in piston assembly.

2. Lack of power.

3. Slow cycling and loss of power.

1. Replace piston assembly.

2. Adjust to adequate air pressure.

3. Check cylinder cap spring for

broken coils or reduced length.

Check if exhaust port of cylinder

cap is restricted.

Here are some common issues that may occur during use.

If the nailer is not working as it should, stop using the tool immediately and resolve the

issue before continuing.

9

TROUBLE SHOOTING CHART

Loading...

Loading...