Page 21For technical questions, please call 1-888-866-5797.ITEM 58169

SAFETYSETUPOPERATIONMAINTENANCE

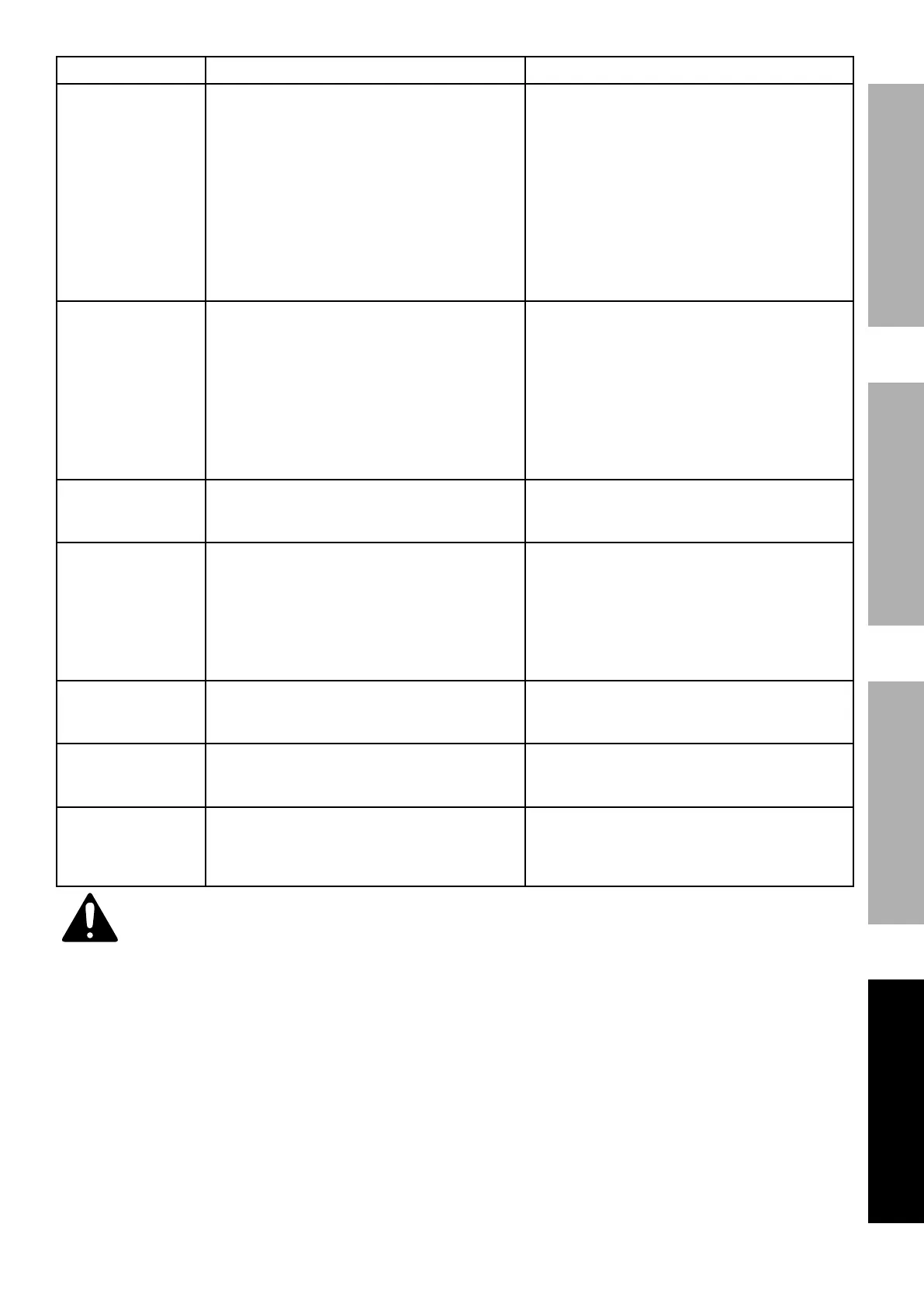

Problem Possible Causes Probable Solutions

Engine misfires

1. Spark plug cap loose.

2. Incorrect spark plug gap or

damaged spark plug.

3. Defective spark plug cap.

4. Old or low quality gasoline/oil mixture.

5. Incorrect compression.

1. Check cap and wire connections.

2. Re-gap or replace spark plug.

3. Replace spark plug cap.

4. Use fresh 87+ octane stabilizer-treated

unleaded gasoline/2-cycle oil mixture only.

Do not use gasoline with more than

10% ethanol (E15, E20, E85, etc.).

5. Diagnose and repair compression.

(Use Engine will not start:

COMPRESSION RELATED section.)

Engine stops

suddenly

1. Fuel tank empty or full of impure or low

quality gasoline/oil mixture.

2. Defective breather valve creating vacuum,

preventing proper fuel flow.

3. Faulty magneto.

4. Disconnected or improperly

connected spark plug cap.

1. Fill tank with fresh 87+ octane stabilizer-

treated unleaded gasoline/2-cycle oil mixture.

Do not use gasoline with more than

10% ethanol (E15, E20, E85, etc.).

2. Test/replace breather valve.

3. Have qualified technician service magneto.

4. Secure spark plug cap.

Engine stops when

under heavy load

1. Dirty air filter.

2. Engine running cold.

1. Clean element.

2. Allow engine to warm up prior

to operating equipment.

Engine knocks

1. Old or low quality gasoline/oil mixture.

2. Engine overloaded.

3. Incorrect spark timing, deposit buildup,

worn engine, or other mechanical problems.

1. Refuel with fresh 87+ octane stabilizer-

treated unleaded gasoline/2-cycle oil mixture

.

Do not use gasoline with more than

10% ethanol (E15, E20, E85, etc.).

2. Do not exceed equipment’s load rating.

3. Have qualified technician diagnose

and service engine.

Engine labors

or stalls when

cultivating

1. Engine speed too low.

2. Cultivating at too great a depth.

1. Adjust throttle to increase Engine speed.

2. Adjust Axle/Drag Bar Assembly in working

position as needed for shallower cultivating.

Excessive

shaking/Cultivator

difficult to control

1. Ground too hard and/or dried out.

2. Axle/Drag Bar Assembly not

correctly set for soil conditions.

1. Wet the ground prior to cultivating.

2. Adjust Axle/Drag Bar Assembly in working

position as needed to achieve correct setting.

After sudden

impact, Engine

runs but Tines

do not rotate

Shaft key or other shear pin

broken by impact to disconnect

Engine and limit damage.

Have qualified technician check and replace

broken shaft key or other shear pins.

Follow all safety precautions whenever diagnosing or servicing the equipment or engine.

Loading...

Loading...