79

Eagle_en_Ver.1.0_2020

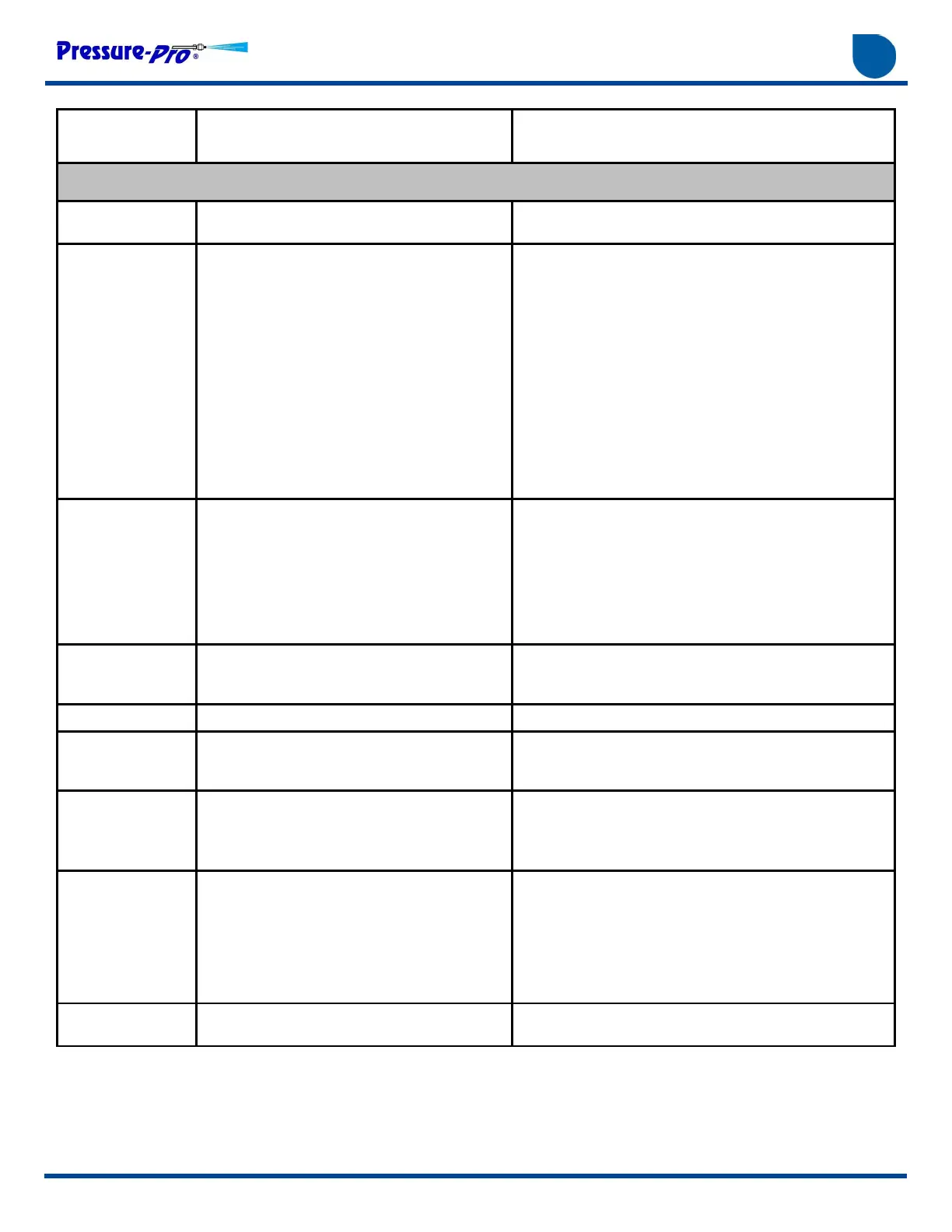

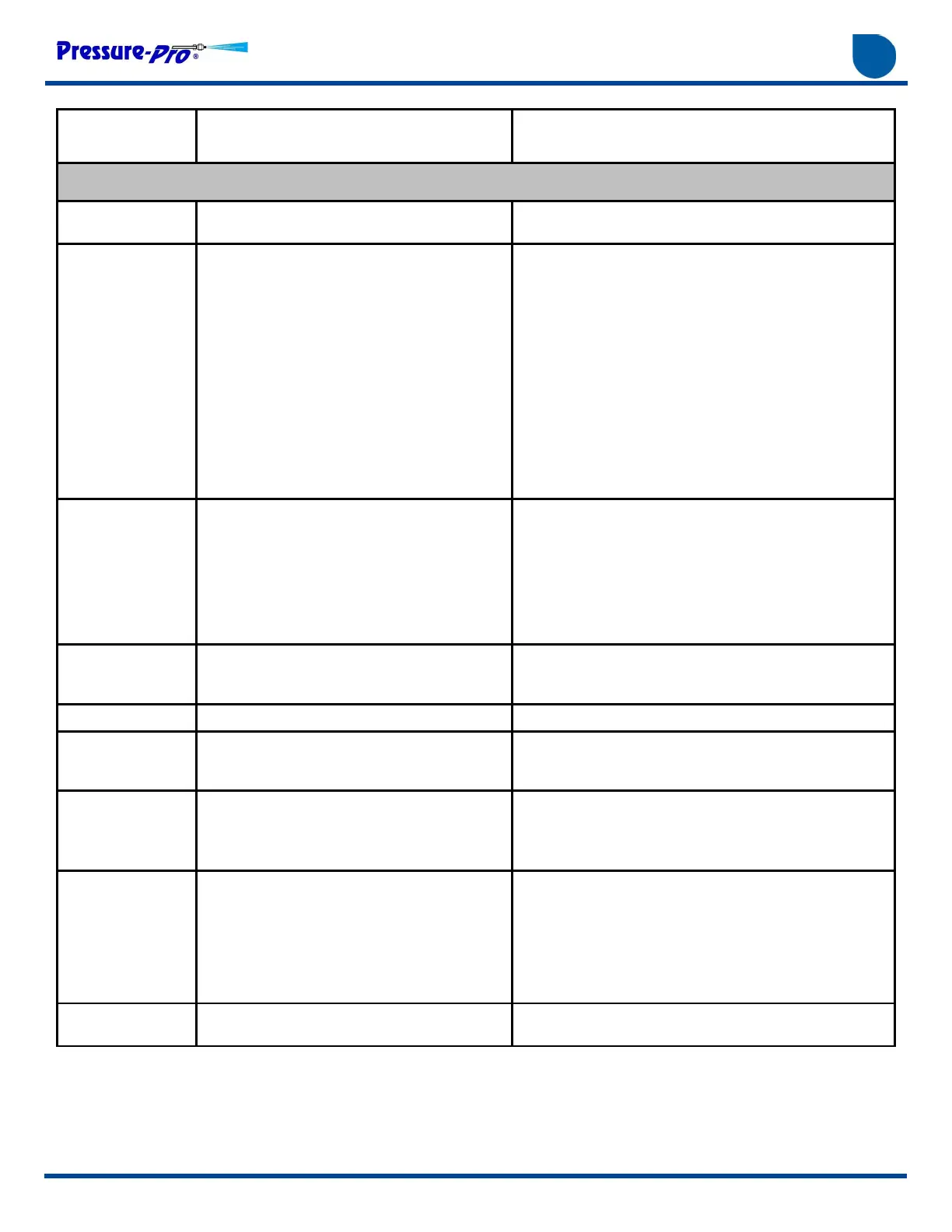

Troubleshooting

K

PROBLEM

PROBABLE CAUSE

(The most recurring probable cause is listed first)

REMEDY

(Repairs should only be made by a qualified technician)

Pumping System

Trigger gun leaks or

will not shut off

-Debris in gun valve assembly. -Clean valve assembly or replace gun.

Pump runs but has

low spray pressure

-Water turned off.

-Nozzle is not installed, is plugged, or sized

incorrectly

-Inlet chemical injection valve is open without the end

of the pickup tube inserted into detergent.

-Priming of pump after run dry.

-Dual wand valve is open.

-Leaky discharge hose or quick coupler. Water

sprays out around nozzle.

-Inlet strainer clogged.

-Belt slippage.

-Unloader valve worn or improperly adjusted.

-Air leak in inlet plumbing.

-EZ start valve is leaking.

-Turn water on.

-Install nozzle, clean or replace with proper size

-Close soap valve or submerge detergent pickup tube into solu-

tion.

-Crack open fitting on high-pressure outlet of pump.

-Close dual wand valve and install high-pressure nozzle.

-Replace hose, quick coupler, or o-ring in the quick coupler.

-Clean and check more frequently.

-Tighten or replace with correct belt

-Install pressure gauge on pump head to adjust pressure.

-Check valve seat on unloader.

-Reseal fittings and inspect inlet hoses for air leaks.

Pump runs but there

is erratic, fluctuating

pressure

-Inadequate incoming water supply.

-Stuck inlet or discharge valves.

-Restricted inlet or air entering the inlet plumbing on

pump.

-Leaking High Pressure seals

-Leaking Low Pressure seals

-Remove hose to check for internal leaks. Increase water supply

flow.

-Clean out or replace worn valves.

-Check fittings and hose for airtight seal, clean inlet strainer

screen.

-Replace seals.

-Pressure feed the pump & replace seals if water leaks from

pump head.

Excessive crankshaft

play or loud, knocking

noise in pump

-Broken or worn bearing or connecting rod in crank-

case

-Replace pump or bearing.

Oil leaking from pump -Loose drain plug or damaged seal -Locate point of oil leakage and replace damaged o-ring/seal.

Water is emitted from

the chemical pickup

tube

-Check-valve malfunctioning. -Repair or replace check-valve.

Inlet injection will not

siphon chemical

-Check valve in strainer clogged.

-Chemical valve not open or clogged.

-Strainer not submerged in solution.

-Detergent hose cut or kinked.

-Clean or replace valve. Rinse after each use.

-Open chemical valve or clean.

-Submerge strainer and replenish chemical.

-Inspect hose, replace as necessary.

Downstream injector

will not siphon chemi-

cal

-Brass knob on injector is closed.

-Unit not in low-pressure mode.

-Soap solution is too thick.

-Detergent hose cut or kinked.

-Strainer plugged or not submerged.

-Internal injector parts corroded or stuck.

-Outlet water temperature too high.

-Open by turning counter clockwise.

-Open dual wand or install low-pressure tip.

-Dilute or use different solution.

-Inspect hose, replace as required.

-Check screen on strainer pickup tube.

-Disassemble, clean or replace.

-Use with cold water (150° Maximum)

Pressure relief reliev-

ing water

-Unloader failure/Coil overheating/Excessive

pressure.

-Turn machine off, wait a few minutes and restart. If problem

continues, take in for repair.

Loading...

Loading...