SPARES

In order to ensure that the Model P404 thermostatic mixing valve continues to provide satisfactory

service, only GENUINE Pegler spare parts must be used.

Spare part order code Description

A 854453 Protective cap complete with screw

B 854447 Hexagon key

C 854454 Service kit

D 854449 (15mm), 854450 (22mm) Tailpiece Strainer kit

E 854451 (15mm), 854452 (22mm) Angle valve strainer kit

F 854456 (15mm), 854457 (22mm) Sealing washer

G 854455 (15mm), 817012 (22mm) Wafer Strainer

• Carefully remove the element and valve assembly and put to one side.

•

Remove the main spring and flow guide and carefully put to one side.

•

Inspect the components for contamination or damage.

•

Clean or replace as necessary

•

Remove the two o rings

•

Clean the valve body and headwork using a propriety de-scaler

•

Thoroughly rinse the body and headwork in clean water.

•

Carefully fit new o rings from the service kit taking care to ensure they are not

damaged and are correctly located.

•

Lubricate the o rings with the lubricant provided.

•

Re-fit the flow guide and spring lubricating the flow guide around the greatest

diameter with the lubricant provided

•

Lubricate the shuttle valve with the lubricant provided

•

Re-fit the shuttle valve and element assembly.

•

Re-fit the headwork ensuring correct tightening

•

Re-fit the valve assembly

•

If after cleaning the valve, and replacing the o ring seals, the valve does not function

correctly, it may be necessary to replace the thermal element.

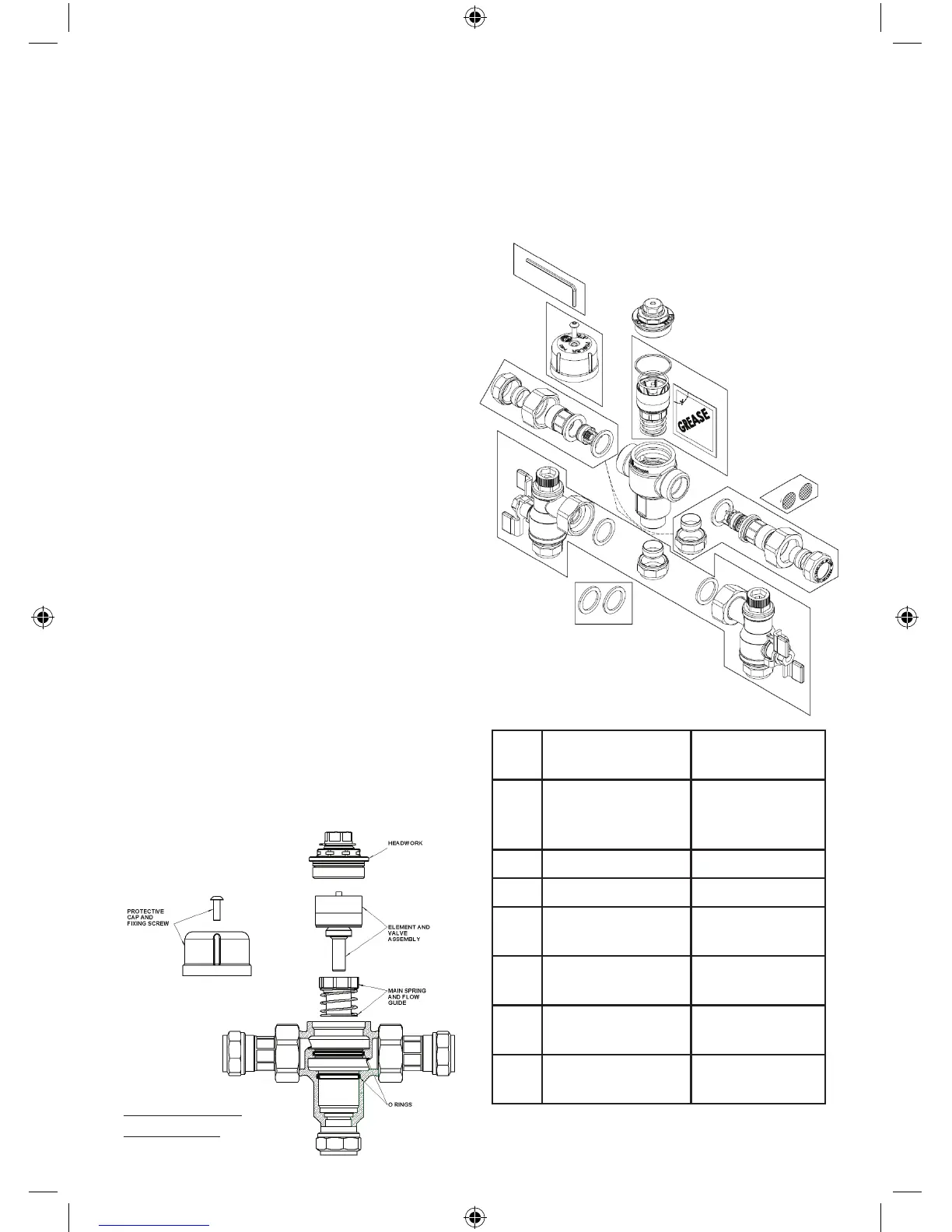

Exploded view of TMV assembly

Exploded view of

TMV assembly

SPARES

In order to ensure that the Prestex Model P404

thermostatic mixing valve continues to provide

satisfactoryservice,onlyGENUINEPeglerspare

parts must be used.

Spare part order

code

Description

1 854453 Protective cap

complete with

screw

2 854447 Hexagon key

3 854454 Service kit

4 854449 (15mm)

854450 (22mm)

Tailpiece

Strainer kit

5 854451 (15mm)

854452 (22mm)

Angle valve

strainer kit

6 854456 (15mm),

854457 (22mm)

Sealing washer

7 854455 (15mm),

817012 (22mm)

Wafer Strainer

1

2

3

4

5

6

4

7

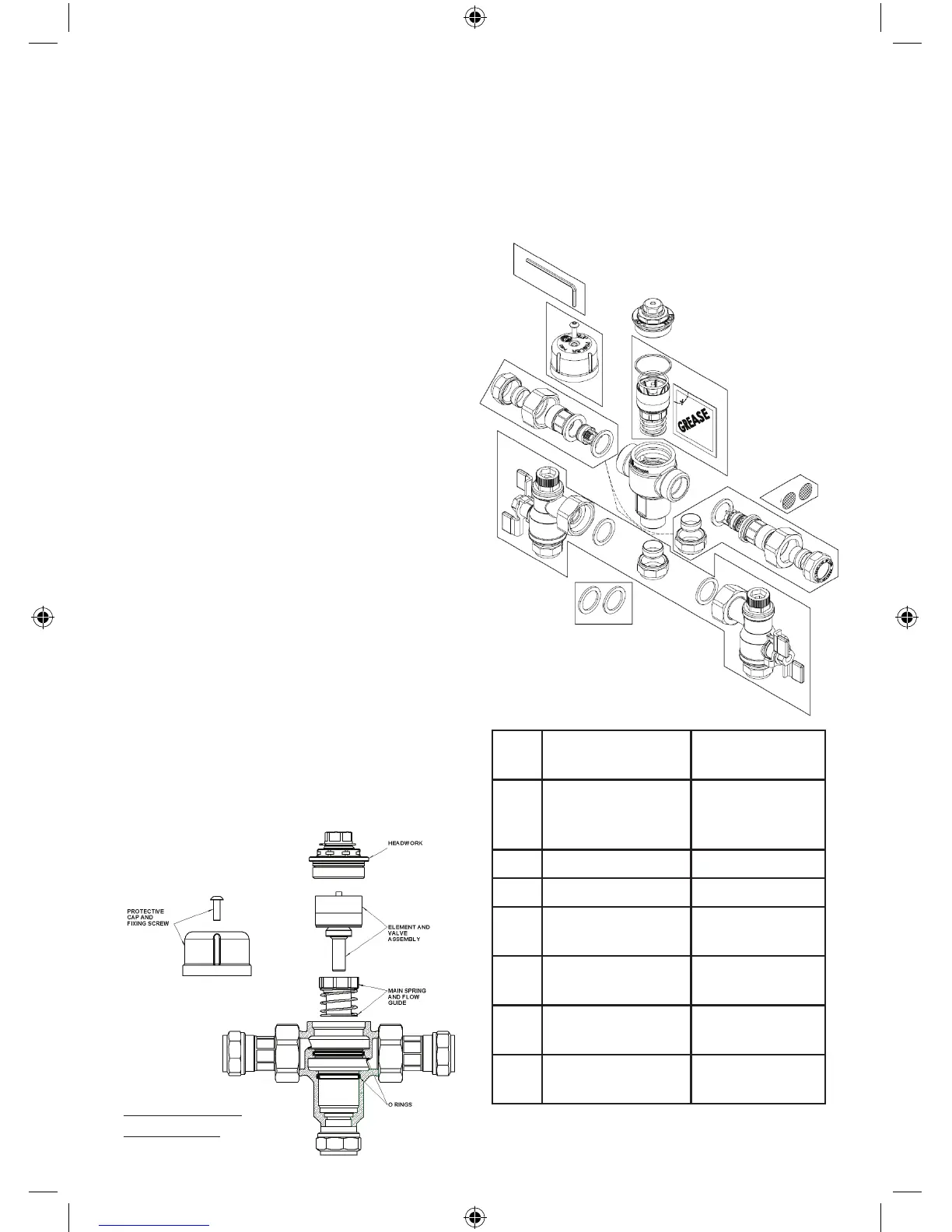

TO SERVICE THE VALVE:

• Isolatethehotandcoldsupply.

• Removethevalvetoacleanworkingarea.

• Removetheprotectivecap.

• Unscrewtheheadworkofthevalve.

• Carefullyremovetheelementandvalve

assembly and put to one side.

• Removethemainspringandowguideand

carefully put to one side.

• Inspectthecomponentsforcontamination

or damage.

• Cleanorreplaceasnecessary

• Removethetwoorings

• Cleanthevalvebodyandheadworkusinga

propriety de-scaler

• Thoroughlyrinsethebodyandheadworkin

clean water.

• Carefullytneworingsfromtheservicekit

taking care to ensure they are not damaged

and are correctly located.

• Lubricatetheoringswiththelubricant

provided.

• Re-ttheowguideandspringlubricating

the flow guide around the greatest diameter

with the lubricant provided

• Lubricatetheshuttlevalvewiththe

lubricant provided

• Re-ttheshuttlevalveandelement

assembly.

• Re-ttheheadworkensuringcorrect

tightening

• Re-ttheassembledvalveandperformthe

comissioning sequence.

• Ifaftercleaningthevalve,andreplacingthe

o ring seals, the valve does not function

correctly, it may be necessary to replace the

thermal element.

TMV3 Model P404.indd 7 13/2/09 15:02:47

Loading...

Loading...