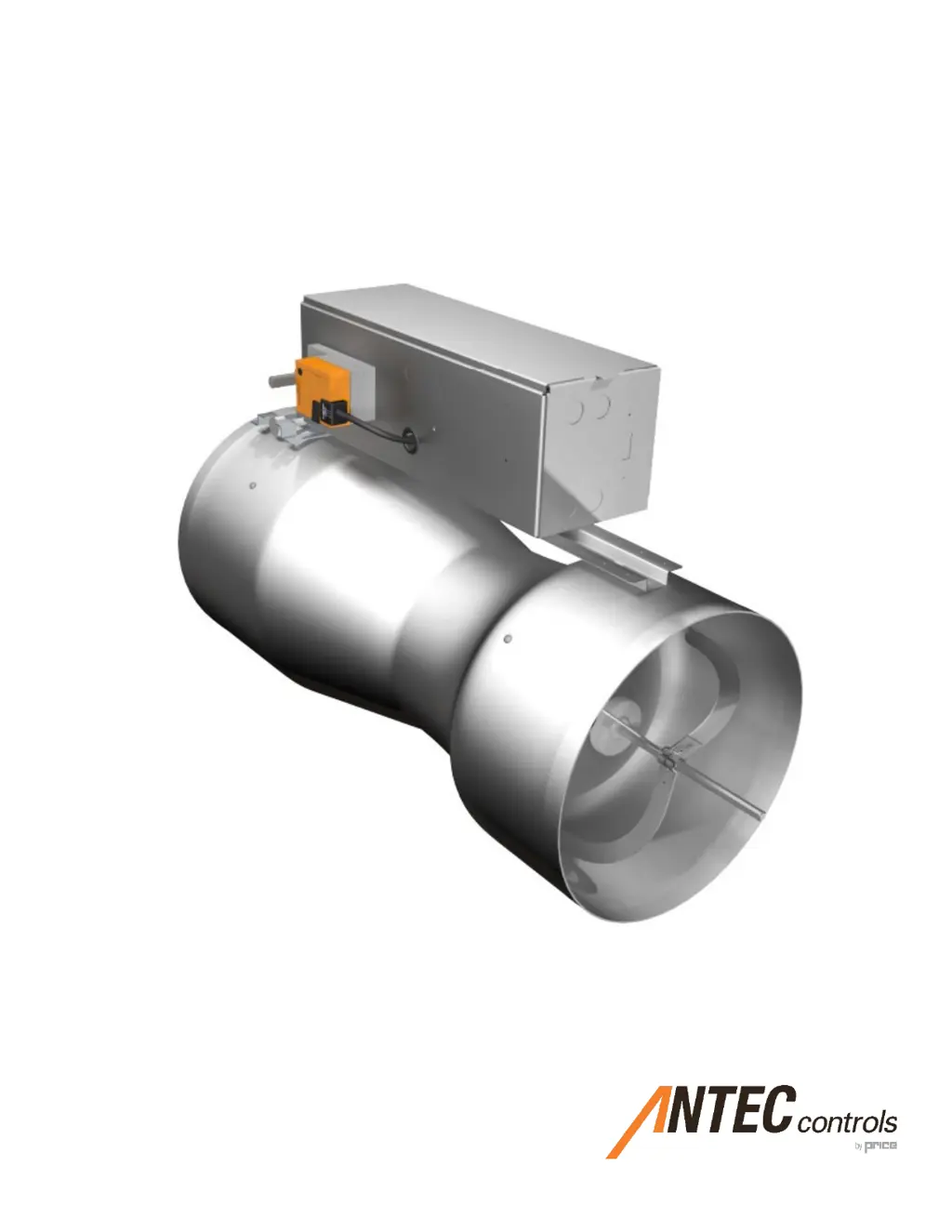

What to do if the Price Control Unit actuator does not operate for Variable Volume Valves?

- RRachel GreenJul 25, 2025

If the actuator isn't working, check these items: * Confirm that power is being delivered to the unit. * Verify the control signal. * Ensure the disconnect switch (if equipped) is not open. * Check if the fuse (if equipped) is blown. * Make sure there are no obstructions in the ductwork.