5

INSTALLATION

MOUNTING YOUR WINCH

1a) The winch is to be mounted into a suitable steel mounting frame using the 4 point foot

mounting system in either a horizontal or vertical plane.

b) It's very important that the winch be mounted on a flat surface so that the three sections (motor,

cable drum and gear housing) are properly aligned.

c) Before commencing installation ensure the mounting facility being used is capable of

withstanding the winches rated capacity.

d) The fitment of winches and/or a frontal protection system may affect the triggering of SRS air

bags.Check that the mounting system has been tested and approved for winch fitment in the airbag

equipped vehicle.

2. Winch mounting frames and /or Frontal Protection Systems are suggested to suit most popular

vehicles.Winch frames are packaged with detailed fitting instructions.

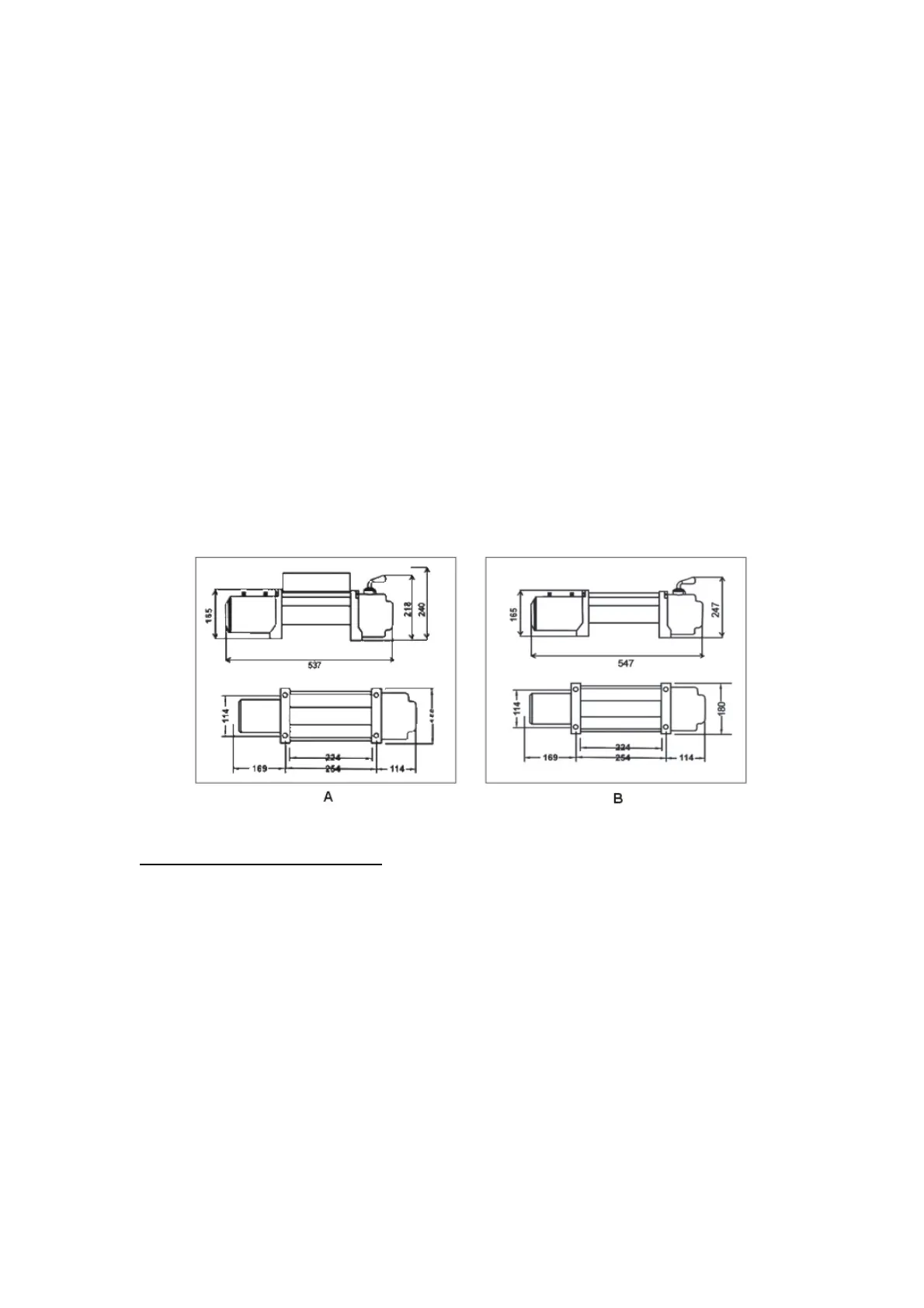

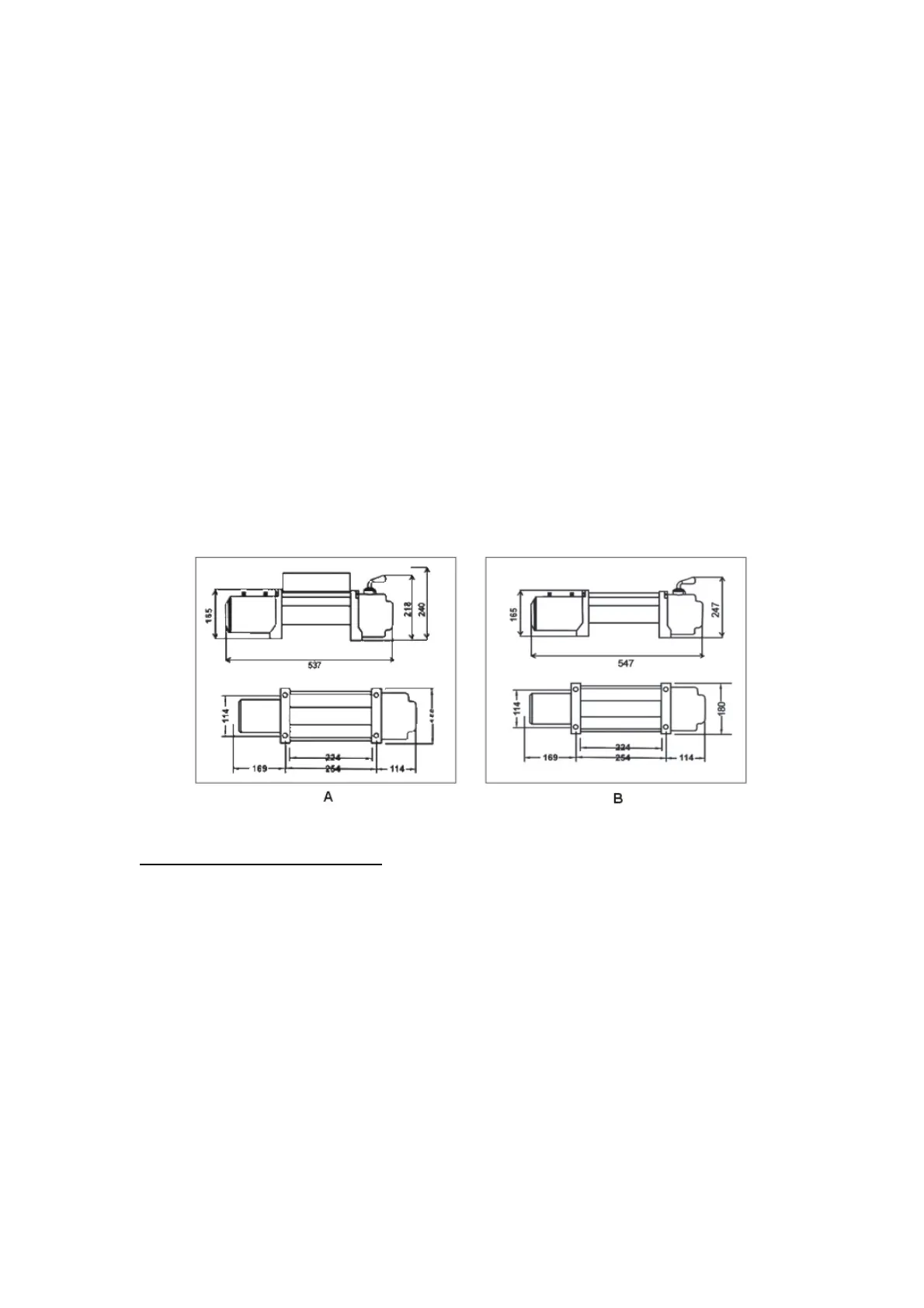

3. Should you wish to manufacture your own mounting plate the dimensions below will

assist.Asteel mount plate 6mm thick is recommended.Fasteners should be steel high tensile grade

5 or better.A poorly designed mount may void warranty.

4. The winch should be secured to the mounting with M12x35 thread precision Grade12 bolts and

spring washers provided.

5. The roller fairlead is to be mounted so as to guide the rope onto the drum evenly.

A is dimensions of 13000lbs, while B is dimensions of 16800lbs.

LUBRICATION INSTALLATION

All moving parts in the winch are permanently lubricated with high temperature lithium grease at

the time of assembly.Under normal conditions factory lubrication will surfice.Lubricate cable

periodically using light penetrating oil.Inspect for broken strands and replace if neccessary.If the

cable becomes worn or damaged it must be replaced.

Loading...

Loading...