5

INSTALLATION (CONTINUED)

ELECTRICAL CONNECTIONS

WARNING: All electrical connections must be performed by a

qualified electrician. Make sure tool is off and disconnected from

power source while motor is mounted, connected, reconnected or

anytime wiring is inspected.

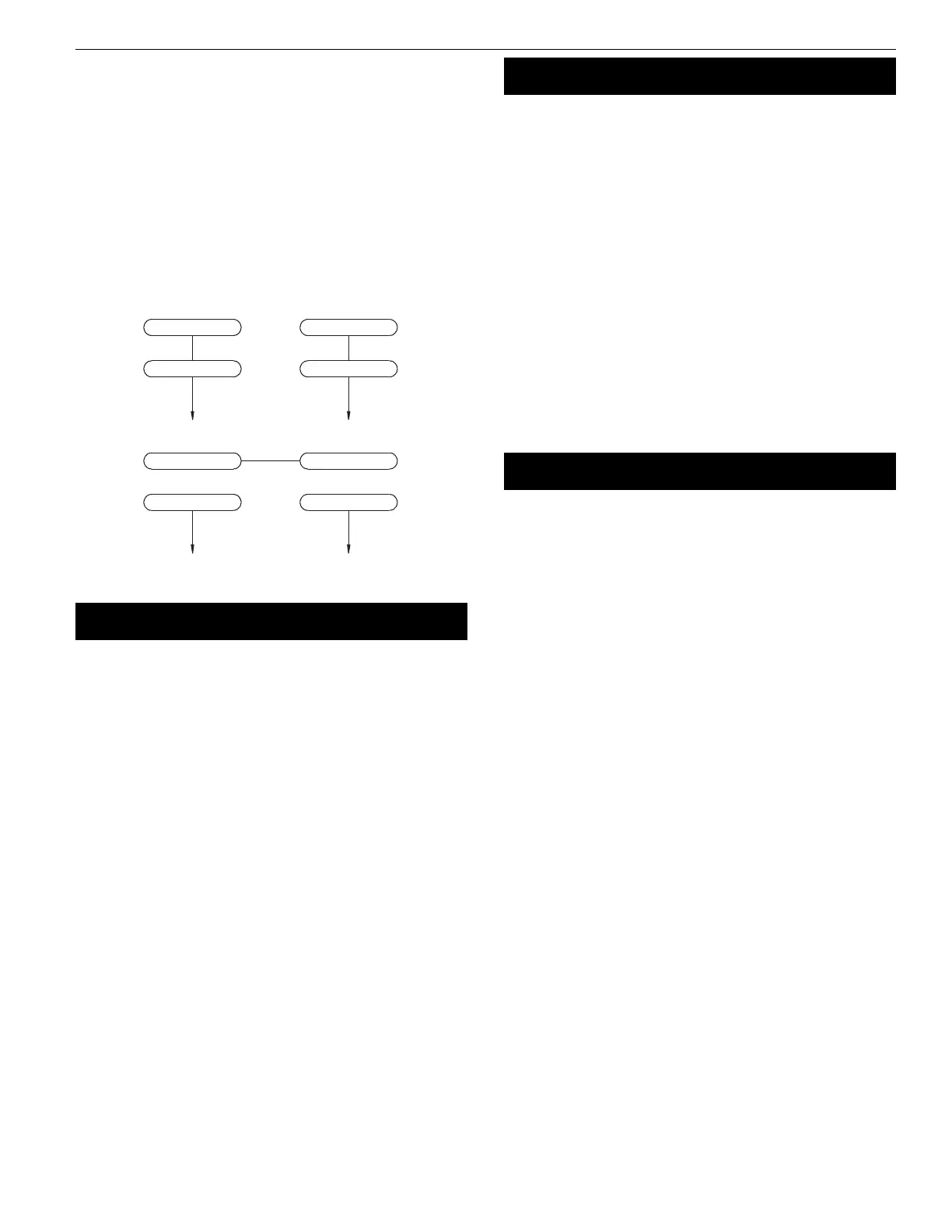

• Motor and wires are installed as shown in wiring diagram (See

Figure 4, page 5). Motor is assembled with approved, 3-conduc-

tor cord to be used at 120/240 volts. Motor is prewired at the

factory for 120 volts.

• To use the grinder with a 240V power supply, have a qualified

electrician rewire motor and attach a 240 volt, I5A three-prong

plug onto grinder line cord.

OPERATION

WARNING: Always wear safety glasses complying with United

States ANSI Z87.1 (shown on package) before commencing power

tool operation.

• Keep a steady, moderate pressure on the work and keep it

moving at an even pace for smooth grinding.

• Pressing too hard overheats the motor and prematurely wears

down the grinding wheels.

• Note the original bevel angle on the item to be sharpened and

try to maintain that angle. Sharpening a cutting edge requires

removing burrs from edge.

• Deburring edge is done best by using the grinder to pull burr

from edge across the bevel angle.

• The grinding wheel should rotate into object being sharpened.

• Dip work into a coolant regularly to prevent overheating.

Overheating can weaken metals.

MAINTENANCE

• As wheels wear, tool rests should be positioned closer to the

face of the wheels.

• The gap between the wheel and the tool rest should not be

greater than

1

/16”. When the wheels are worn to the extent that

the

1

/16” maximum gap cannot be maintained, the wheels

should be replaced.

• Models PR736 and PR738: Replacement wheels should have a

minimum rated speed of at least 3600 RPM.

• Model PR7310: Replacement wheels must have a minimum

rated speed of 1800 RPM.

• Maximum wheel diameter is 6” for PR736, 8” for PR738, and 10”

for PR7310.

• To loosen nuts holding the wheels, disconnect power and push

a wood wedge between the tool rest and the wheel to keep

the shaft from turning. The threads on the right side of the

grinder (facing unit) are right hand; threads on the left side are

left hand. Tighten nuts securely before operating the grinder.

• For grinding efficiency, wheels should be dressed periodically,

especially if they become clogged from grinding soft metals.

WARRANTY

PRM warrants their products to be free of defects in material or

workmanship. This warranty does not cover defects due

directly or indirectly to misuse, abuse, normal wear and tear, failure

to properly maintain the product, heated, ground or otherwise

altered, or used for a purpose other than that for which it was

intended. The warranty does not cover expendable and/or wear

parts (i.e. v-belts, coated screws, abrasives), damage to tools arising

from alteration, abuse or use other than their intended purpose,

packing and freight. The duration of this warranty is expressly lim-

ited to one year parts and labor, unless otherwise noted below

beginning from the date of delivery to the original user.

The obligation of PRM is limited solely to the repair or replace-

ment, at our option, at its factory or authorized repair agent of any

part that should prove deficient. Purchaser must lubricate and

maintain the product under normal operating conditions at all

times. Prior to operation become familiar with product and the

included materials, i.e. warnings, cautions and manuals. Failure to

follow these instructions will void the warranty.

This warranty is the purchaser’s exclusive remedy against PRM for

any deficiency in its products. Under no circumstances is PRM liable

for any direct, indirect, incidental, special or consequential damages

including lost profits in any way related to the use or inability to

use our products. This warranty gives you specific legal rights

which may vary from state to state.

Figure 4 – Wiring Diagram

3-Red 2-Gray

4-Yellow

1-Black

120V

240V

3-Red

1-Black

2-Gray

4-Yellow

PR736, PR738 and PR7310

Loading...

Loading...