9

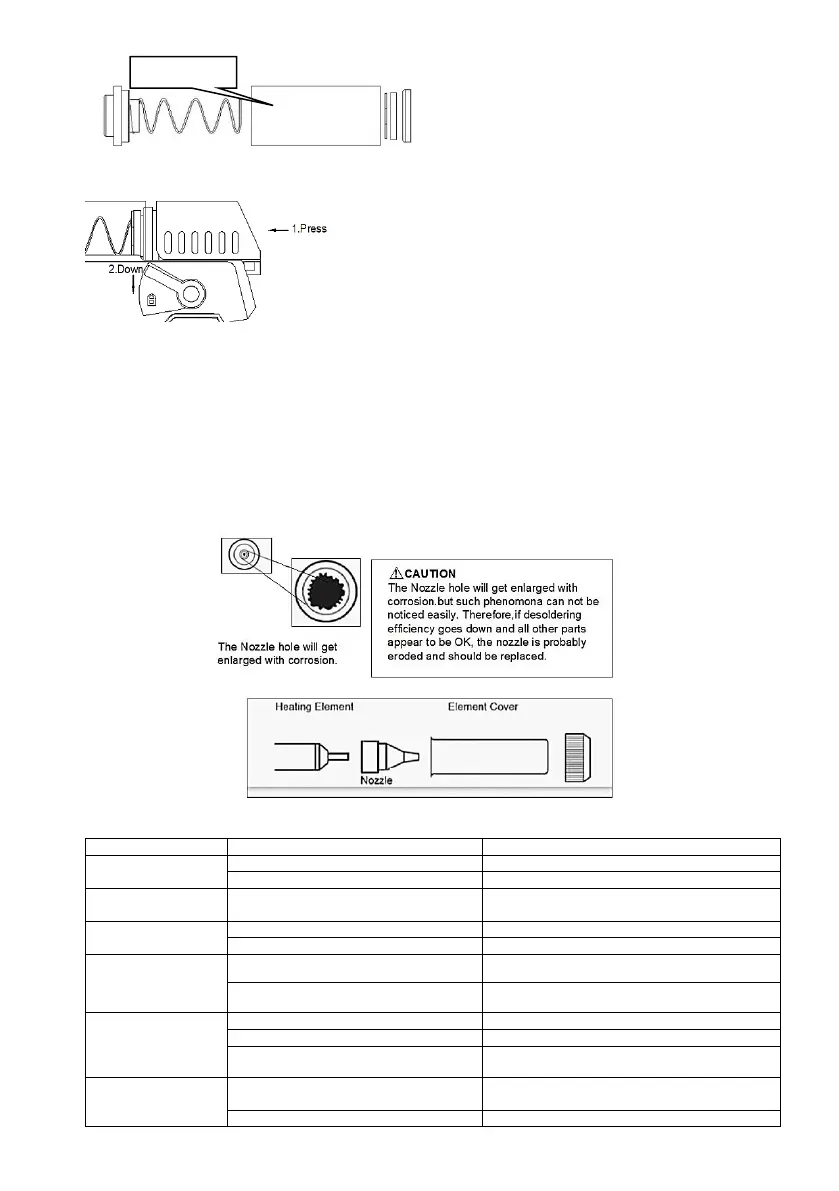

3. Put the spring back to glass tube, then put glass tube back. Press the back holder, then the knob will

bullet down and become locked automatically.

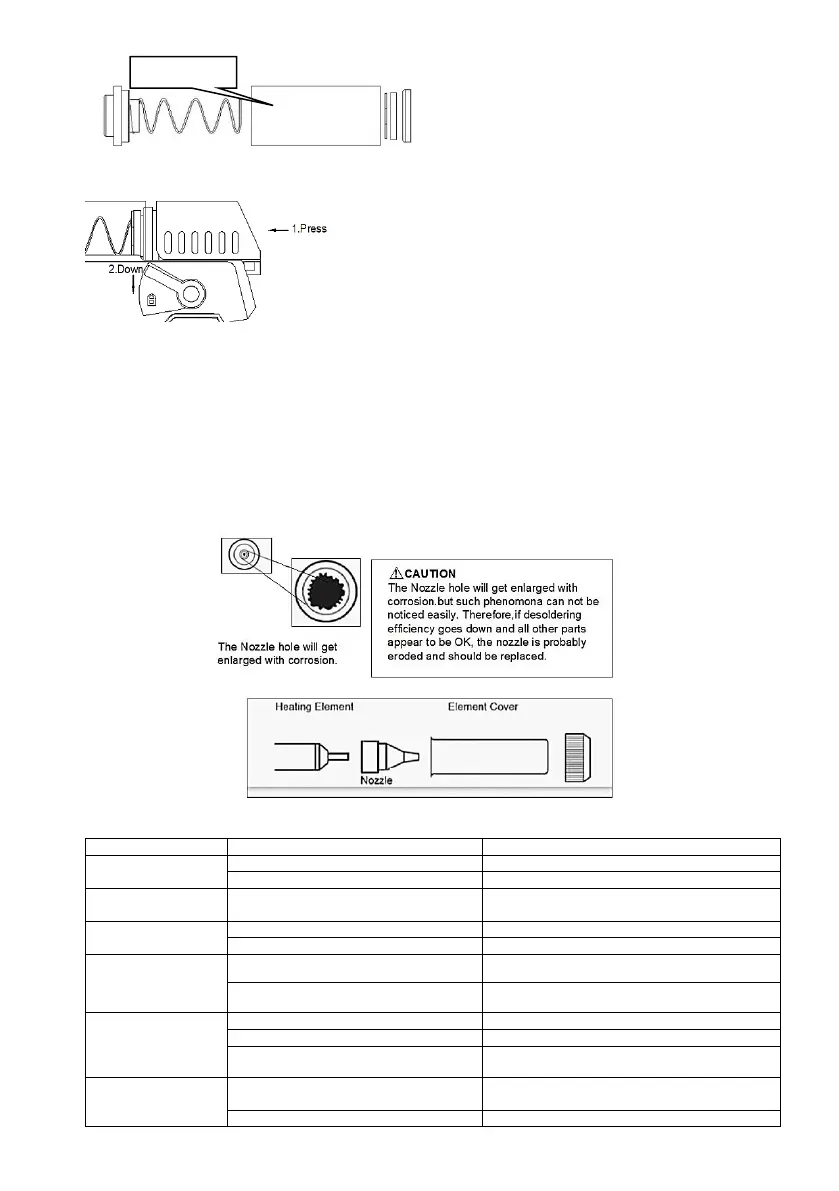

Instruction

1. After each operation is finished, let the desoldering gun suck in the air 3-5 times soon, which can clean the

solder waste inside the pipe.

2. If the operation interval is about 20 minutes, use the cleaning tool to clean the pipe after having the

desoldering gun suck in the air.

3. When you find the desoldering efficiency gets down, please use the cleaning pin to clean the pipe

immediately.

4. If the operation interval is long, it is advised to adjust the temperature to about 200℃. When you use it

again, you can reset it to the working temperature.

5. When the glass tube has absorbed about 1/2 solder waste, clean it immediately. When you find the filter is

getting hardened, replace it immediately.

Troubleshooting

Check the power connection and plug it in

Replace the fuse(3.15A / 250V)

Unreasonable setting of temperature

Reset a proper temperature

Check the connection of vacuum outlet

Check the installation of glass tube

Excessive solder waste in glass tube

Clean solder waste in the glass tube

Loading...

Loading...