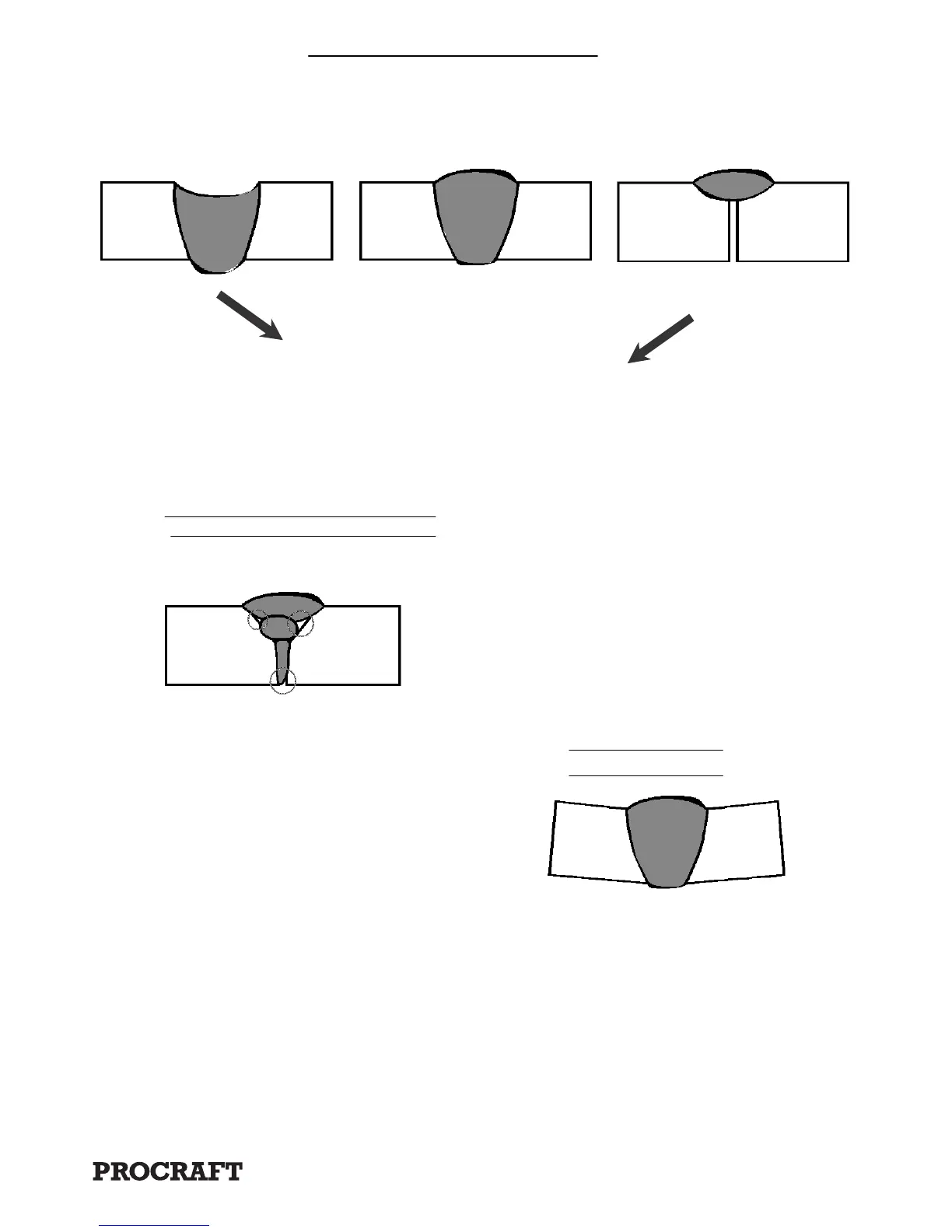

Weld droops on top

and underneath, or falls

through entirely,

making a hole

Weld is visible underneath and

bulges slightly on top.

Weld does not contact the

joint fully, just on the

surface.

and Solutions

1. Excessive material at weld:

Reduce wire feed speed

2. Overheating:

Increase welding speed and

ensure that welding speed is kept

steady.

Welding not adhering properly

Gaps present between weld and previous

bead or between weld and work piece.

and Solutions

1. Dirty work piece:

Make certain that work piece is clean

and free from oil, coatings, and other

residues.

2. Insufficient weld material:

Increase wire feed speed.

3. Incorrect welding technique:

Place stringer bead at correct place in

joint. Adjust work piece position or weld

angle to permit proper welding at

bottom of work- piece.

Pause briefly at sides when using a

weave bead. Keep arc on leading edge

of weld puddle. Hold gun at proper

angles and make tack welds to help

hold pieces.

and Solutions

1. Work pieces too thick/close:

Joint design must allow weld to

reach bottom of groove and allow

proper welding procedures.

2. Incorrect welding technique:

Maintain

1

/

2

”or less stick out. Keep

arc on leading edge of weld puddle.

Hold gun at proper angles.

3. Insufficient weld material:

Increase wire feed speed.

4. Insufficient weld heat:

Reduce Welding Speed.

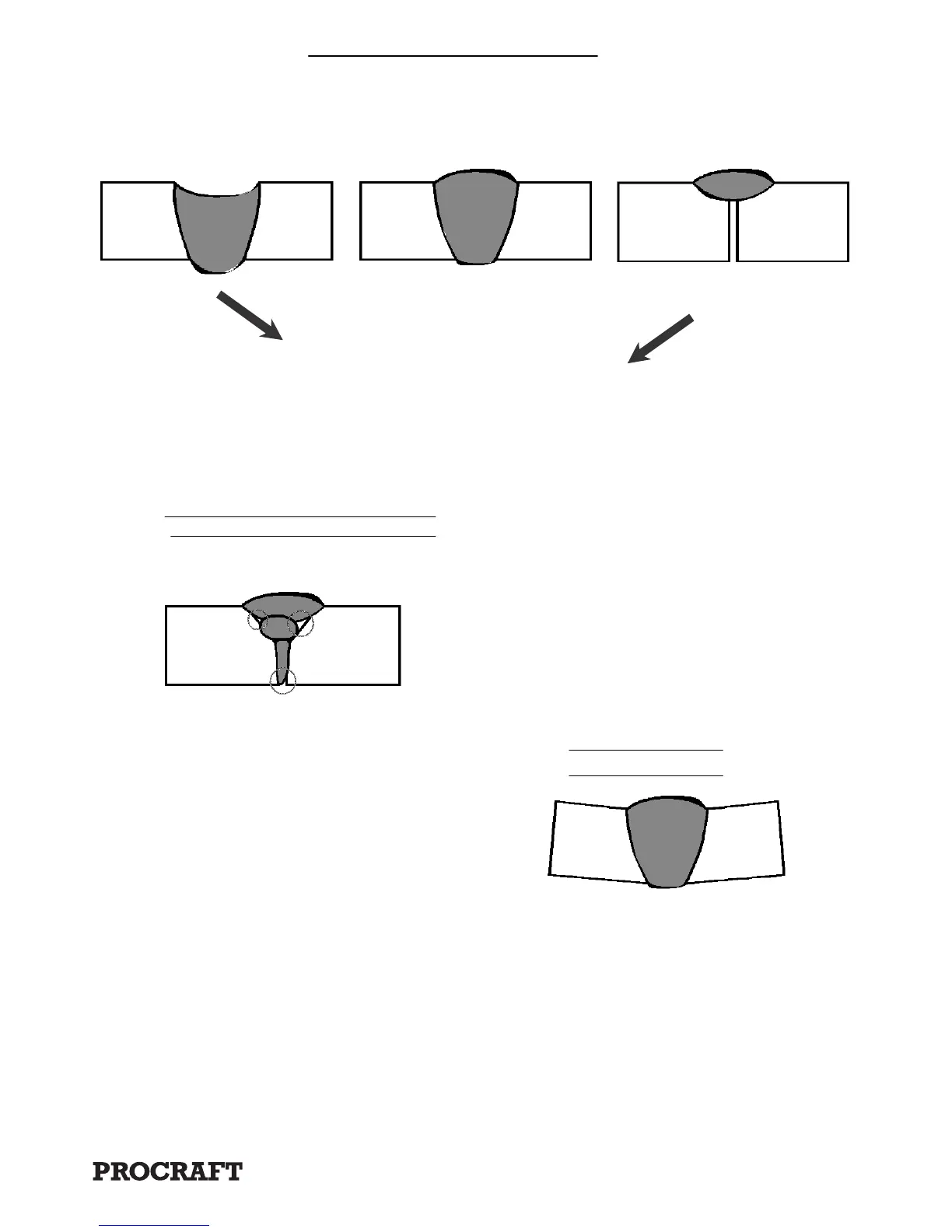

Bent at joint

and Solutions

1. Improper clamping:

Make sure that pieces are clamped

securely in place.

2. Excessive heat:

Weld a small portion and allow

cooling before proceeding.

Reduce wire feed speed.

Loading...

Loading...