EN

25

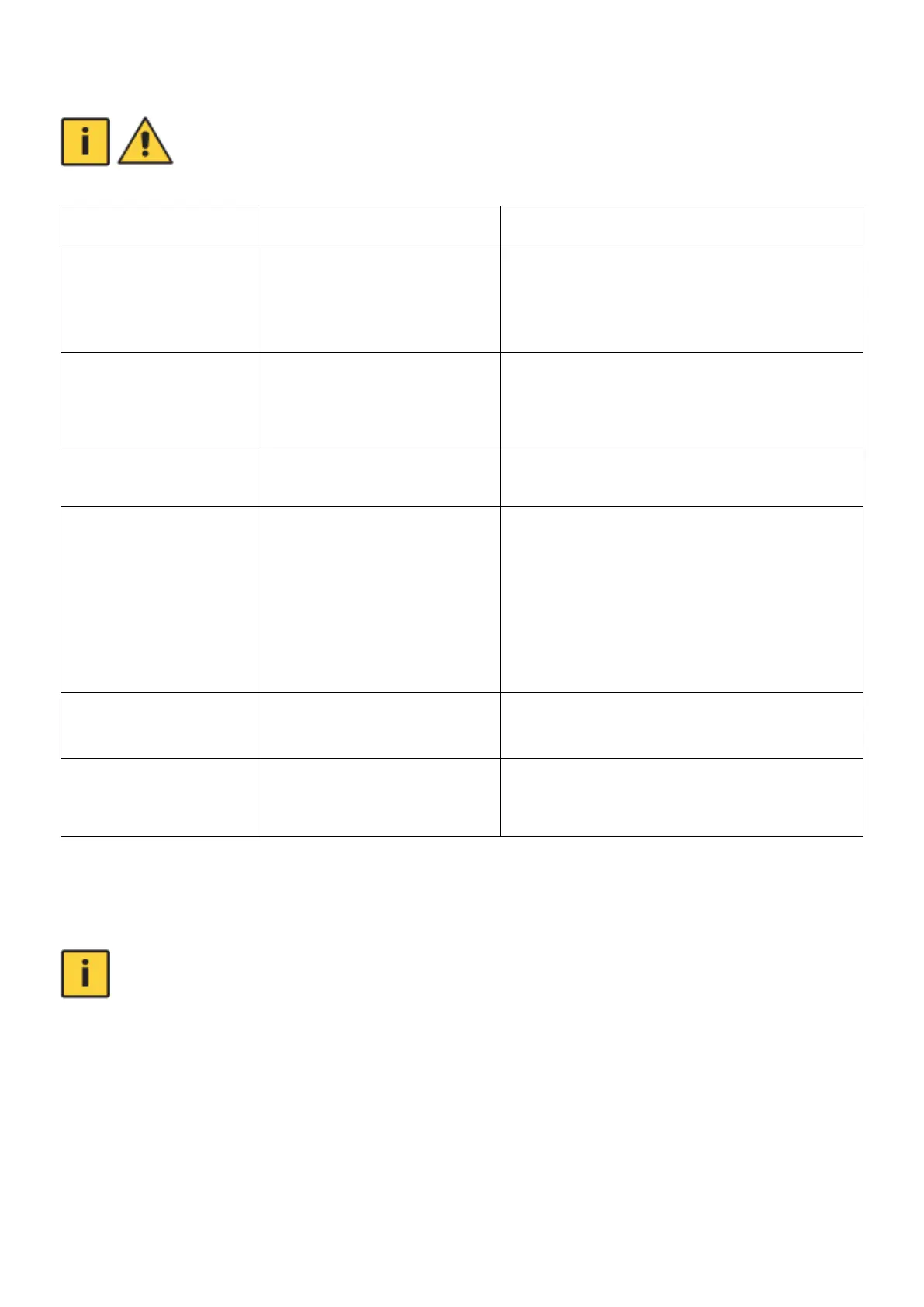

9 Common operational issues

Causes associated with the

unit

Causes not associated with the unit

1. The unit is damaged.

2. Restart button is stuck.

3. Parameter setting display

is open.

1. The voltage is lower than 230 V.

2. The pump is broken.

3. Faulty wire connection.

1. The unit is damaged.

2. Check valve is stuck.

3. Water contains iron

ore and iron oxides

1. The unit is damaged.

2. Pressure range is too low.

1. The unit is damaged.

2. The controller piping is

broken

1. Lack of water

2. Pump is broken.

3.Leak at pump inlet

4.Maximum delivery height of the pump is

lower than the switching pressure +0.3 bar

(MODE 1)

5. Maximum delivery height of the pump is

lower than the shutdown pressure (MODE 2)

1. The unit is damaged.

2. The pressure sensor is

damaged.

The actual pressure in the pipe is higher than

9.9 bar for more than 5 seconds.

Starting and stopping time is repeatedly less

than 30 seconds after the 15th time when

there is a leak in the pipe.

10 Suggestion

1. Try suggesting to customers that they use the "dE 1" mode. The "dE 2" mode can be used on other

special occasions.

2. When the user uses the "dE 2" mode, the switch-off pressure must be lower than the maximum delivery

height of the pump, the switch-off pressure should be 0.3-0.5 bar lower than the maximum delivery height

of the pump. For example, if the maximum delivery height of the pump is 40 metres, the switch-off

pressure should be set to 3.5-3.7 bar.

Loading...

Loading...