Check that the electricity supply voltage is the same as

that listed on the specification plate and in the

machine’s documentation.

3.2 Installation

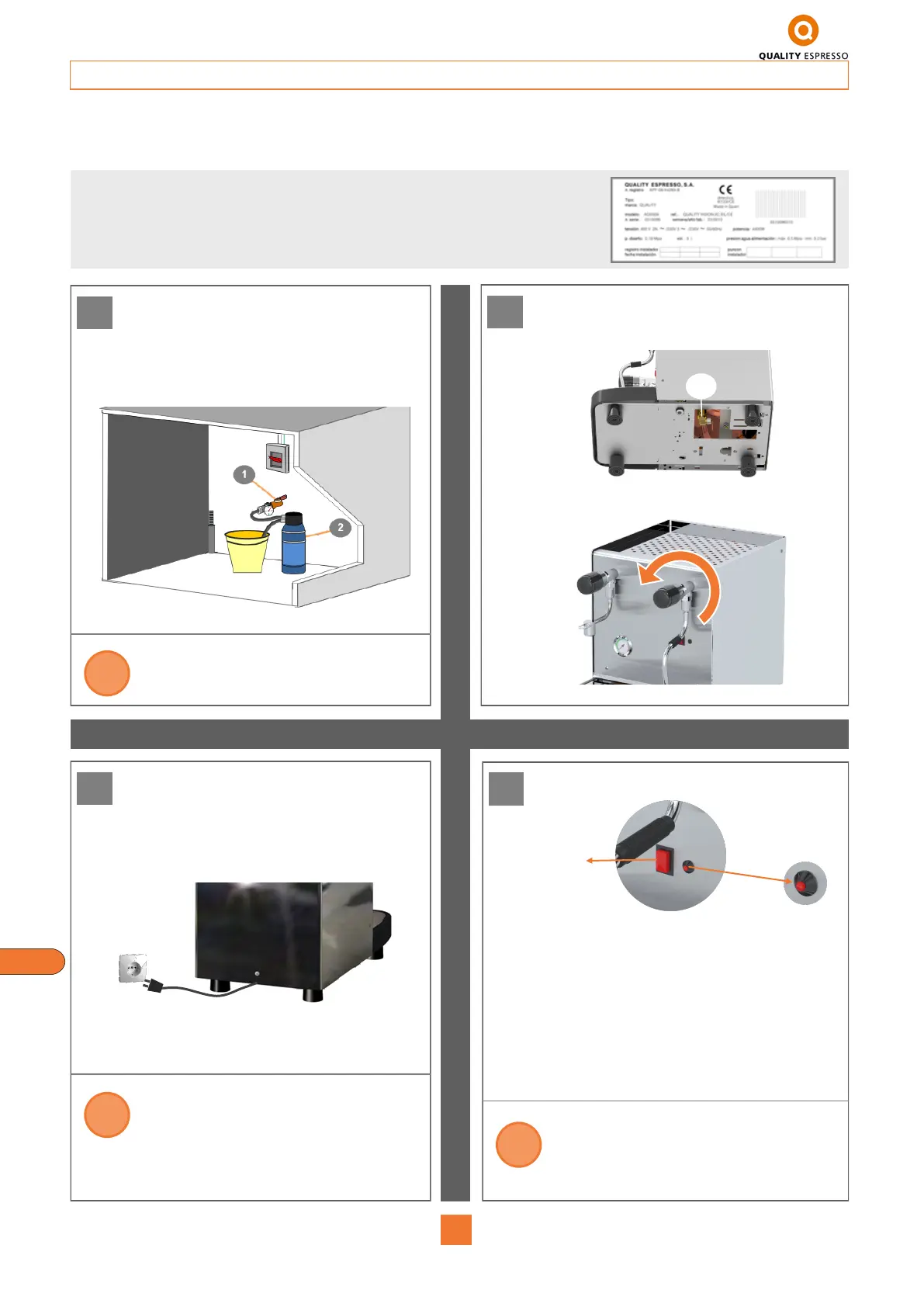

Place the machine on the workbench, and

connect the water supply tube from the

stopcock (1) to the water softener (2).

Drain the output of the water softener into a

bucket, until the water flows clean.

It is recommended to use water with a hardness

between 5-8 dHº (8-14 fHº) to avoid calcification and to

obtain an optimal quality of the product.

3.2.1 Machines with mains water connection

Once the machine has been unpacked, the following steps should be performed:

1

i

Connect the output of the water softener to the

machine’s water input (3).

Supply water by opening the stopcock (1).

Open the steam tap.

2

33

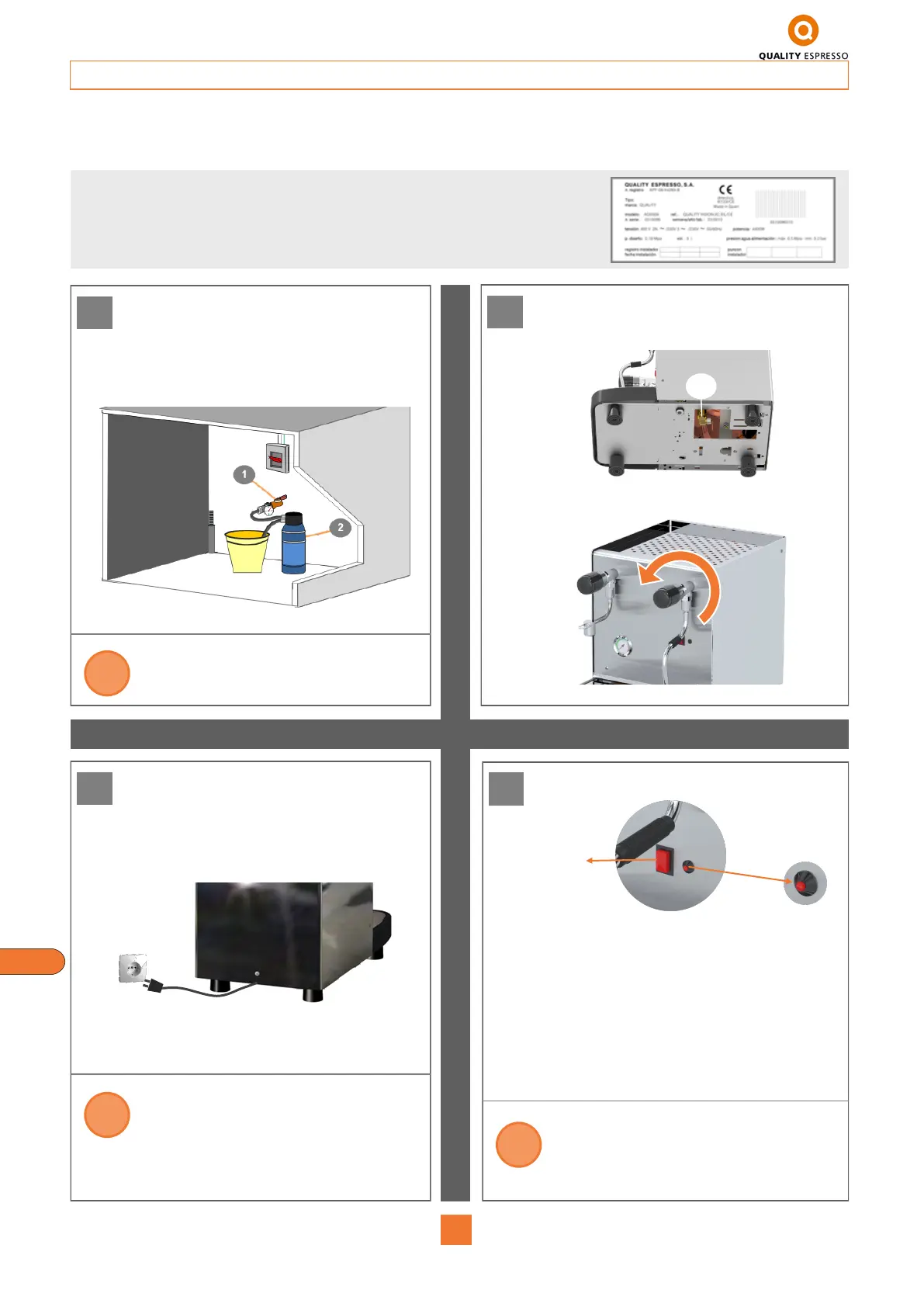

Connect the plug to the appropriate socket

according to the current electrical standards

of the area.

You should not use extension cords or outlet adapters

of any kind to connect the machine to the electricity

network.

The network connection cable should never be rolled

up; instead, it should be fully extended to avoid

possible overheating.

3

i

Press the main power switch.

- At this moment the boiler will automatically fill with water,

a process that is indicated by the led located next to the

main power switch.

Once the filling process has finished, the indicator will turn

off and the boiler heating cycle will start. This process lasts

for approximately 15 minutes, and at this moment the

steam tap should be closed.

After this time and with pressure reading of approximately

1.3 bars on the gauge, the machine is ready to work.

If an adequate water level is not detected in the boiler within

a certain time, the water level LED indicator (next to the

main power switch) will blink, indicating a water level

warning. This warning can be cancelled by turning the

machine off and on again.

4

i

Main switch

Water level LED

Indicator

EN

3

Loading...

Loading...