Troubleshooting Guide

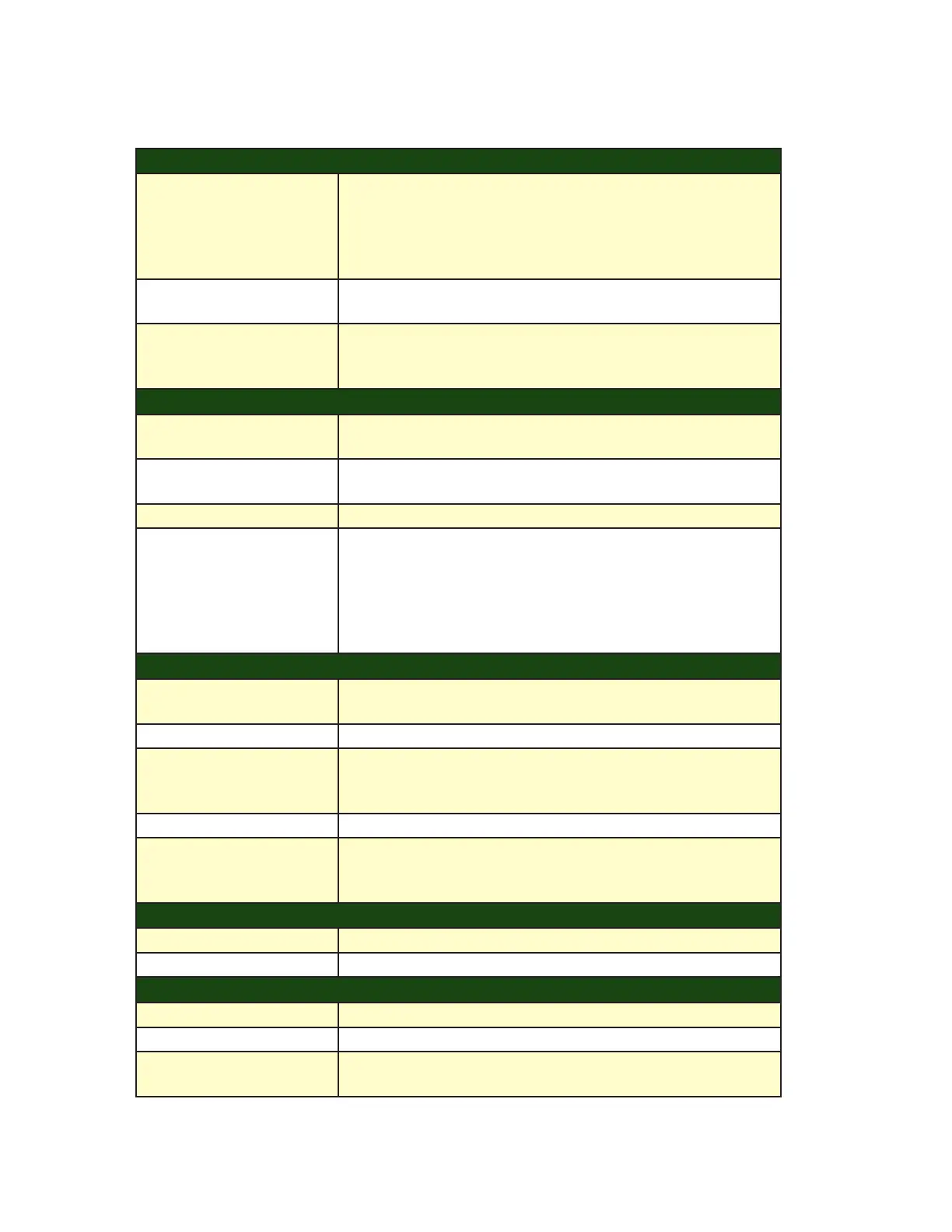

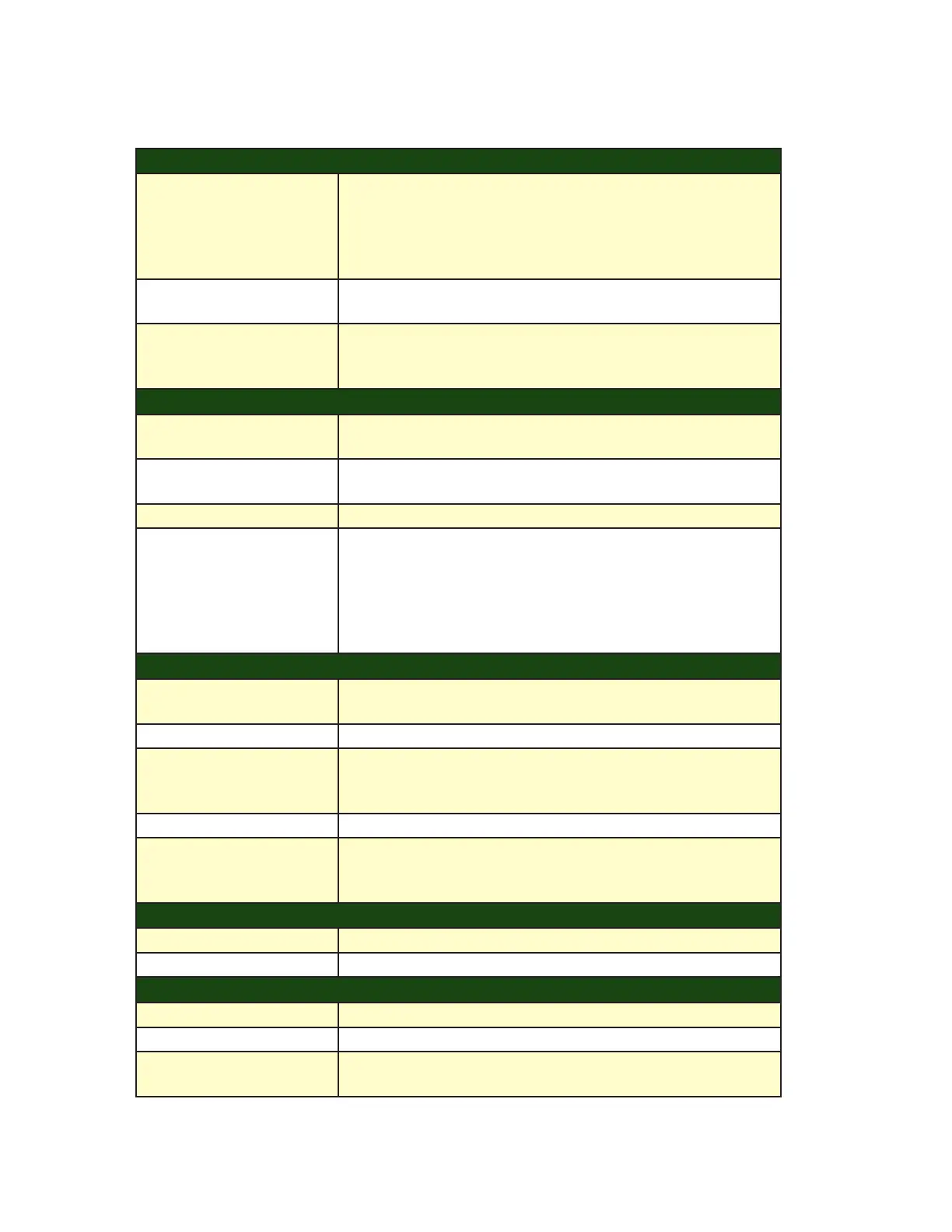

INJECTION CYLINDER NOT INJECTING OR INJECTING AT SLOW RATE

Too low of pressure 1. Check the hose connecting the backpack or pump to the HTI to

make sure that it is not kinked. 2. Make sure that the ends of the

hoses located within the manifold are not loose, tighten them if need

be. 3. Check to make sure that the filter is not obstructed. 4. Turn up

pressure (do not exceed 175 psi).

Compressed soil/rocks at

injection site

Move probe to new application site

Clogged product outflow ports Pick out the 4 hole injection ports with a paper clip. Ensure prod-

uct is properly diluted as thicker products can impede movement

throughout HTI.

INJECTION CYLINDER NOT FILLING

Kink, twist or obstruction in

hose

Remove obstruction

Clogged inline filter Check for debris, residues or particulates. If present, clean out filter

using methods outlined within the manual.

Fill button wont activate Remove, lubricate and clean fill button components

Injection Cylinder stuck O-Rings are dry and need to be lubricated or have rolled back on

themselves causing a seize. If they have rolled back, remove the

o-ring and replace. Operating the HTI at high pressures will some-

times cause the O-ring to roll back on itself. If O-ring continuously

rolls back on it itself, adjust the pressure to lessen the likelihood of

this occurring.

CYLINDER WON’T STOP FILLING

Fill button depressed and

won’t come back up

Pressure is too high. Keep pressure below 150 psi.

Fill button on too tight Untighten the button to alleviate the dowel pin.

Spring no longer maintaining

pressure against nylon ball

Replace the spring. For a temporary fix, pull the spring apart to get it

back to original form. It is necessary to replace the spring in the long

term as the spring will have lost its integrity after repeat alterations.

Nylon ball is too worn Replace nylon ball of all of the fill button components

Port where fill button compo-

nents insert into manifold are

worn and will not hold a seal

Replace the manifold.

CYLINDER IS LEAKING

Freeze/thaw damage Replace cylinder.

O-Rings worn out Replace O-rings.

ELECTRONIC COUNTER STOPS WORKING

Water Damage Replace Counter

Dead Lithium Battery Replace Counter

Lost Connection Remove 4 screws that hold counter. Pull out of frame and check

connection

POSSIBLE CAUSE SUGGESTED SOLUTION

Product Ordering: www.treecarescience.com 5

Loading...

Loading...