OIM‐600056 Rev.0 14

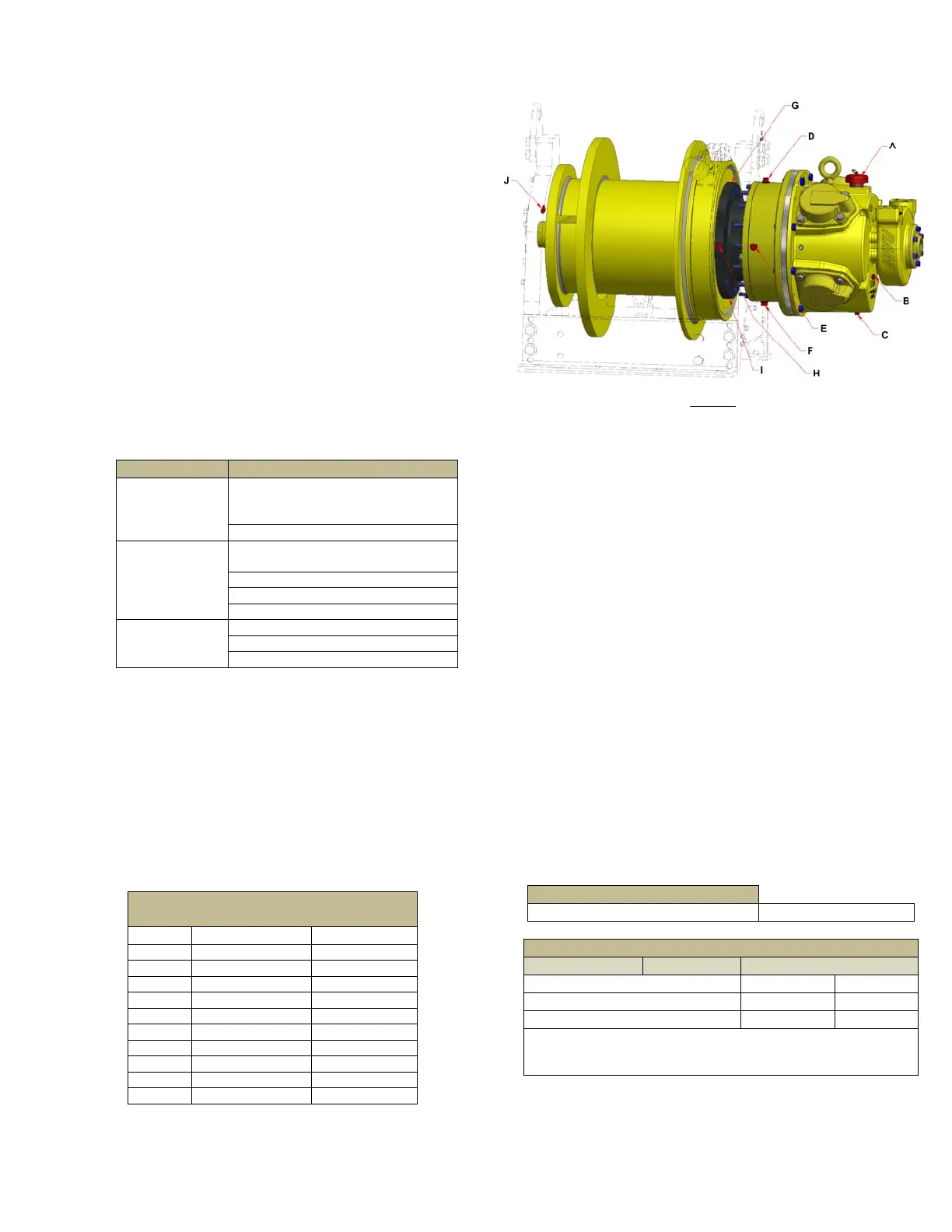

Figure9

MaintenancePoints

(Figure9)

POINT COMPONENT DESCRIPTION

A MOTOR FILL/VENT

B MOTOR LEVEL

C MOTOR DRAIN

D DISCBRAKE FILL/VENT

E DISCBRAKE LEVEL

F DISCBRAKE DRAIN

G* GEARBOX FILL/VENT

H* GEARBOX LEVEL

I* GEARBOX DRAIN

J DRUMBEARING ZERK

5.4. AirLineLubricator

Always use an air line lubricator installed as close as practical to

theairinletofthemotororcontrolvalve.Therateatwhichthe

lubricatorinjectsoilintotheairstreamshouldbeat8to10drops

perminute.Maintainalevelofoilinthelubricatorbowl.

Usean

ISOVG100(SAE30W)oilandcheckregularly.

5.5. Mufflers

A quality muffler, sufficiently sized for the air flow of the motor,

shouldbeinstalledontheexhaustportofthemotoraswellasthe

localcontrolvalve.Mufflerscanbecomerestrictedfromdustand

debrisand,overtime,willdegradetheperformance(linepulland

linespeed)ofthe

winch.Checkthemufflersperiodically.

5.6. Lubrication‐Winch

Thewinch has a numberoflubrication and fluidlevel points that

needtobemonitoredandmaintained(seeFigure9).Toensurea

long service life, all points requiring lubrication must be serviced

with the correct time interval as indicated in the Interval Chart

following.

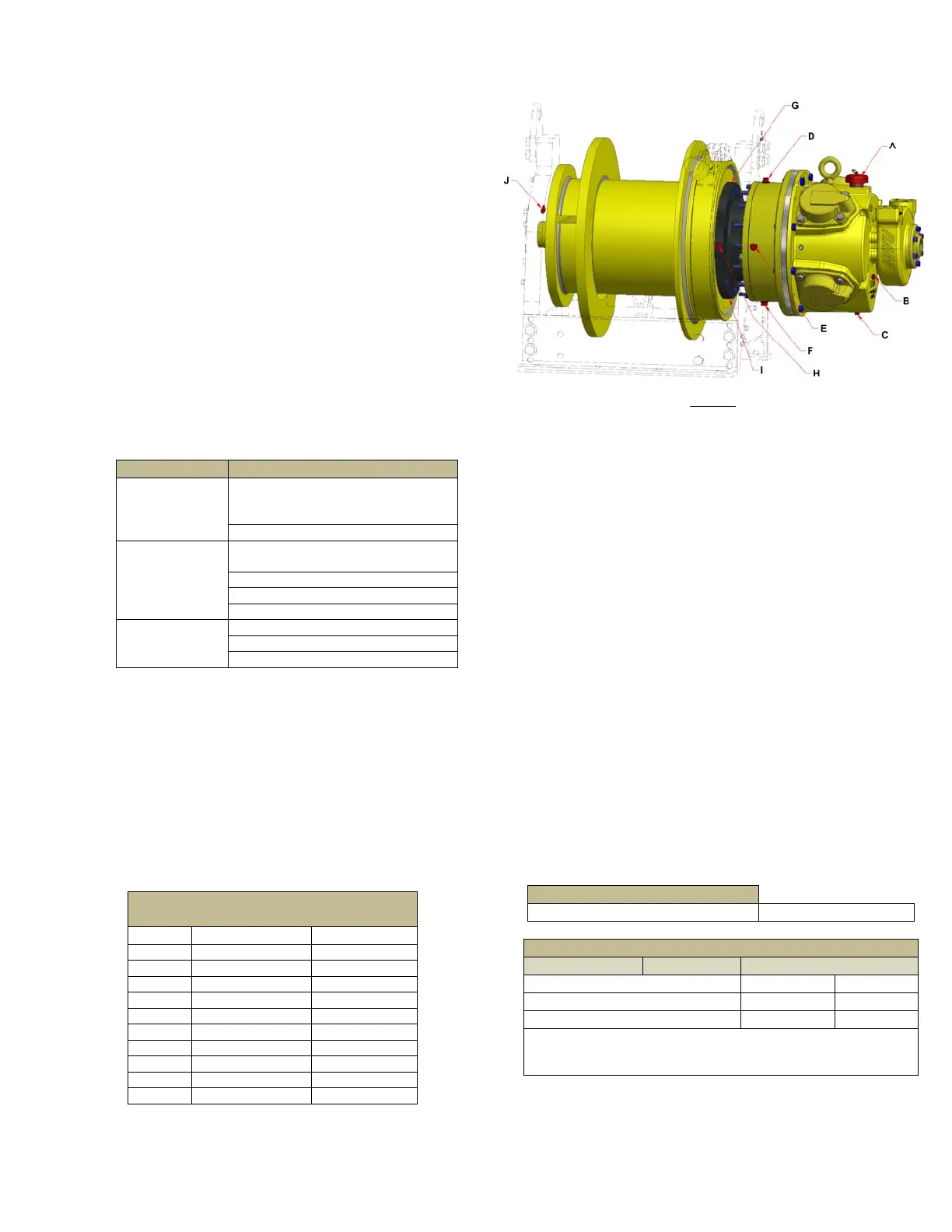

Interval LubricationChecks

Startofeachshift

Check flow and level of the air line

lubricator (approx. 8 to 10 drops per

minuterequiredatmax.motorspeed).

Checkwinchmotoroillevel.

Monthly

Lubricatecomponentssuppliedbygrease

fittings.

Inspectandclean/replaceairlinefilter.

Checkgearboxoillevel.

Checkdiscbrakeoillevel.

Yearly

DrainandRefillgearboxoil.

Drainandrefillwinchairmotoroil.

Drainandrefilldiscbrakeoil.

These recommended lubrication intervals are based on

intermittent operation of the winch defined as eight hours per

day,fivedaysperweek.Anumberofotherfactorsalsoinfluence

the lubrication intervals, such as:duration of use, load range,

protection of the unit from the environment, corrosive

environments, ambient temperatures,

etc. These factors may

requireashorterintervalbetweenlubricationchecks.

Figure 9 and the Maintenance Points table below highlights the

winchlubricationcheckpoints.

Motor–(PointsA/B/C)–Theoillevelintheairmotorneedstobe

maintained and checked at the start of each shift.Correct

lubricationisakeyfactorinproperlymaintainingtheairmotorin

ordertoensureitslongevityandoperatingefficiency.Themotor

internalcomponentsaresplashlubricatedbytheoil inthesump.

Therefore,itisextremelyimportanttomaintaintheoillevelwith

a high quality extreme pressure, rust

inhibiting, non‐detergent

motoroil.Fill/Addoilto the motor via thefill/ventcap (Point A)

locatedinthetopofthemotorhousing.Properoillevels can be

checkedatthelevelplug(PointB).

During normal operation moisture can collect in the motor

housing.This will be even more

prevalent in cold temperature

environments where there is a large deviation between the

operating temperature of the motor and the ambient air

temperature.This accumulated moisture should be drained

regularly (Point C) after the winch has been allowed to sit for a

period of time to allow the water to

separate out from the oil.

Anyfluiddrainedoffshouldbedisposedofinanenvironmentally

safeandresponsiblemanner.

The following tables give the oil capacity and recommended

viscosityforgivenambienttemperatureranges.

OilCapacity(approx.)

Motor 5qt.(4.7liters)

AirMotorOilRecommendation

AmbientTemp. ISOIndex SAE

Below 32

F (0°C)

VG46 10W

32

Fto80

F (0°C to27°C)

VG68 20W

Above 80

F (27°C)

VG100 30W*

Winchesareshippedfromthefactorywith5qts.ofISOVG100(SAE

30W) oil for customer to fill motor with prior to use.Motor is

drainedofoilpriortoshipment.

DiscBrake– (Points D/E/F)–Thefrictioncomponents of thedisc

brake run in oil to maximize life as well as minimize

Loading...

Loading...