OIM‐600056 Rev.0 15

environmentaleffectsontheseinternalcomponents.Careshould

be taken so as not to overfill the disc brake as this could inhibit

the setting and releasing of the brake and cause additional drag

and wear to the disc brake components.Fill/Add oil to the disc

brake

thru the fill/vent plugonthe top ofthe disc brakehousing

(Point D).Check the level by removing the level plug (Point E).

Draining the oil from the disc brake can be accomplished by

removingtheplugonthebottomofthehousing(PointF).

Thefollowingtablegives

theoilcapacity.Usethesameoilinthe

disc brake as used in the air motor – see Air Motor Oil

Recommendationintheprecedingsection.

OilCapacity(approx.)

DiscBrake 1qt.(0.9liters)

Gearbox – (Points G/H/I)‐Duringthe first hours of operation of

the reduction gears, due to the contact between surfaces that

have not been run‐in, you may find metallic particles in the oil.

Undoubtedlytheseparticleswillhaveanegativeeffectonthelife

of the gears and bearings

within the gearbox.To reduce the

number of metallic particles in the oil we recommend changing

theoilinthegearboxafterthefirst100hoursofworkingandthen

every1,500‐2000hoursorevery12months.Thelubricantused

should be petroleum based, non‐detergent gear fluid containing

anti

‐oxidation,antifoamingandextremepressureadditives.

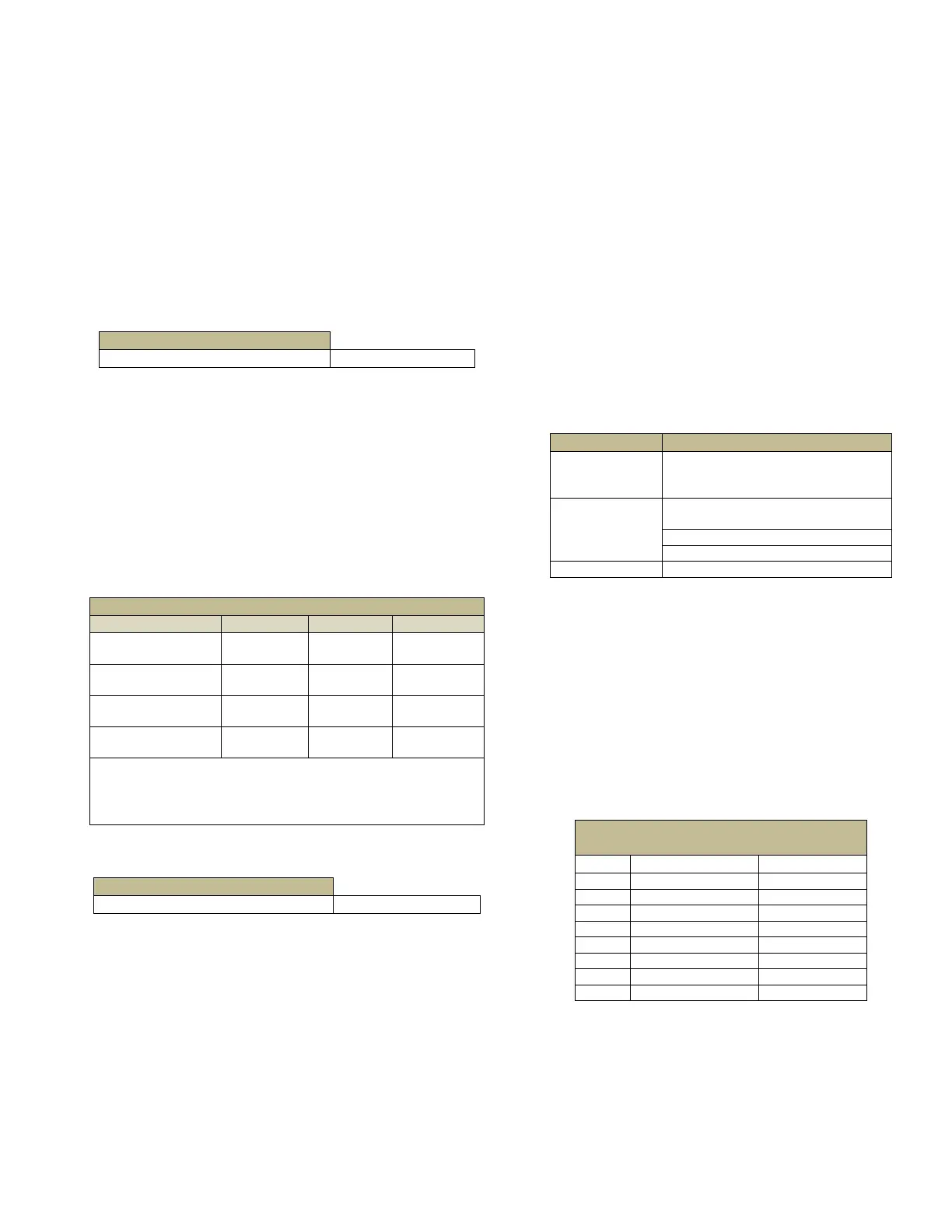

GearboxOilRecommendation

AmbientTemp ISOIndex AGMA# SAEGear

‐4°Fto140°F

(1)

(‐20°Cto60°C)

VG220 5EP 90W

14°Fto86°F

(‐10°Cto30°C)

VG150 4EP 90W

50°Fto113°F

(10°Cto45°C)

VG220 5EP 90W

86°Fto140°F

(2)

(30°Cto60°C)

VG320 6EP 140W

Footnotes:

1. Foroperatinginthisambienttemp.rangeasyntheticoilormulti‐gradeoilis

recommendedwithapourpointof10°Flowerthanthemin.ambienttemp.

2. Foroperatinginthisambienttemp.rangeasyntheticoilisrecommendedfor

properlubricantlifeatelevatedtemps.

Thefollowingtablesgivetheoilcapacity:

OilCapacity(approx.)

Gearbox 4.4qts.(4.2liters)

Toverifythelevelofoilwithinthegearbox,rotatethedrumuntil

thefillport(PointG)isatthetopandthelevelplug(PointH)isat

the 3 o’clock position.Remove the level plug – oil should be

visibleatthisport.Addadditionalthroughthe

fillplugifrequired.

Rotate the drum sothat the drain plug (Point I) is down to drain

completelyifperforminganoilchange.

Drum Bearing – (Point J)‐ The winch drum rotates on a ball

bearingoppositethegearboxend.Thisbearingislubricatedbya

greasezerklocated

atthetopofthebearingretainerplate.

Onamonthlybasis,pumpaqualitybearinggrease(5or6pumps)

through the grease zerk on the top of the pillow block housing.

Routinely pumping grease into the housing acts to replenish the

lubricantaswellasflushoutanycontaminants.

Dependingonthe

amountofusageandthe environment, this processmayneedto

berepeatedduringtheoperationcycle.

Ram recommends using Shell Gadus V220 2 Grease. Or other

extremepressureandanti‐wearlithiumgrease.

5.7. Lubrication–Levelwind

In addition to the winch lubrication items covered in Sect. 5.6,

some units are supplied with a levelwind that has several

lubrication and fluid level points that need to be monitored and

maintained(seeFigure10).Toensurealongservicelife,allpoints

requiring lubrication must be serviced with the

correct time

intervalasindicatedintheIntervalChartfollowing.

Interval LubricationChecks

Startofeachshift

Check flow and level of the air line

lubricator (approx. 8 to 10 drops per

minuterequiredatmax.motorspeed).

Monthly

Lubricatecomponentssuppliedbygrease

fittings.

*CleanandLubricateACMEScrew

Checkgearboxoillevel.

Yearly DrainandRefillgearboxoil.

*Before deploying or retrieving long distances of wire rope,

cleanandlubricatetheACMEScrew.

These recommended lubrication intervals are based on

intermittent operation of the winch defined as eight hours per

day,fivedaysperweek.Anumberofotherfactorsalsoinfluence

the lubrication intervals, such as:duration of

use, load range,

protection of the unit from the environment, corrosive

environments, ambient temperatures, etc. These factors may

requireashorterintervalbetweenlubricationchecks.

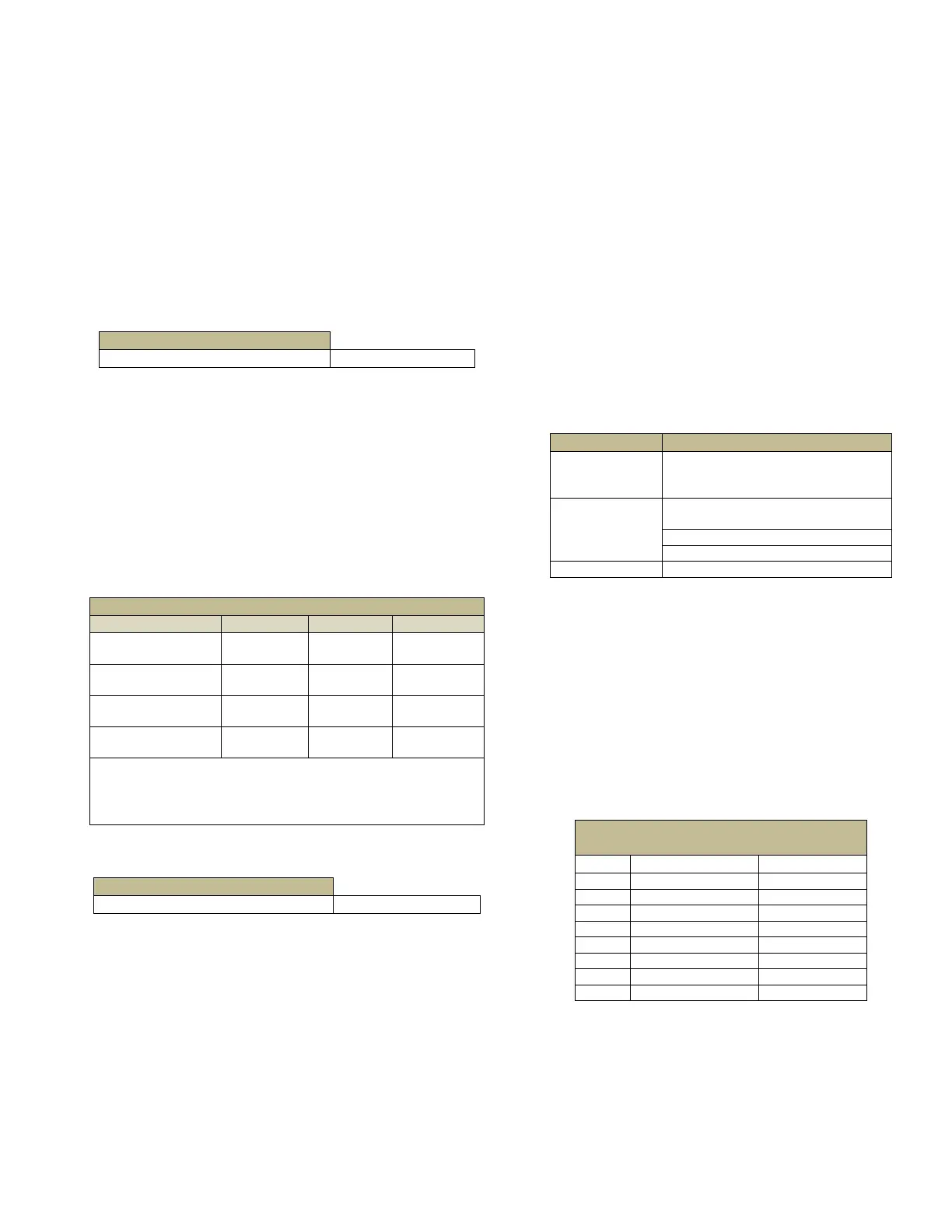

Figure 10 and the Maintenance Points table below highlights the

levelwindlubricationcheckpoints.

MaintenancePoints

(Figure10)

POINT COMPONENT DESCRIPTION

A AIRLINELUBE LEVEL

B Motor FILL/VENT

C Motor LEVEL

D Motor DRAIN

E GEARBOX LEVEL/FILL/DRAIN

F ACMESCREW BRUSH

G GUIDEBARS ZERK

H WIREROPEROLLERS ZERK

Loading...

Loading...