OIM‐600056 Rev.0 16

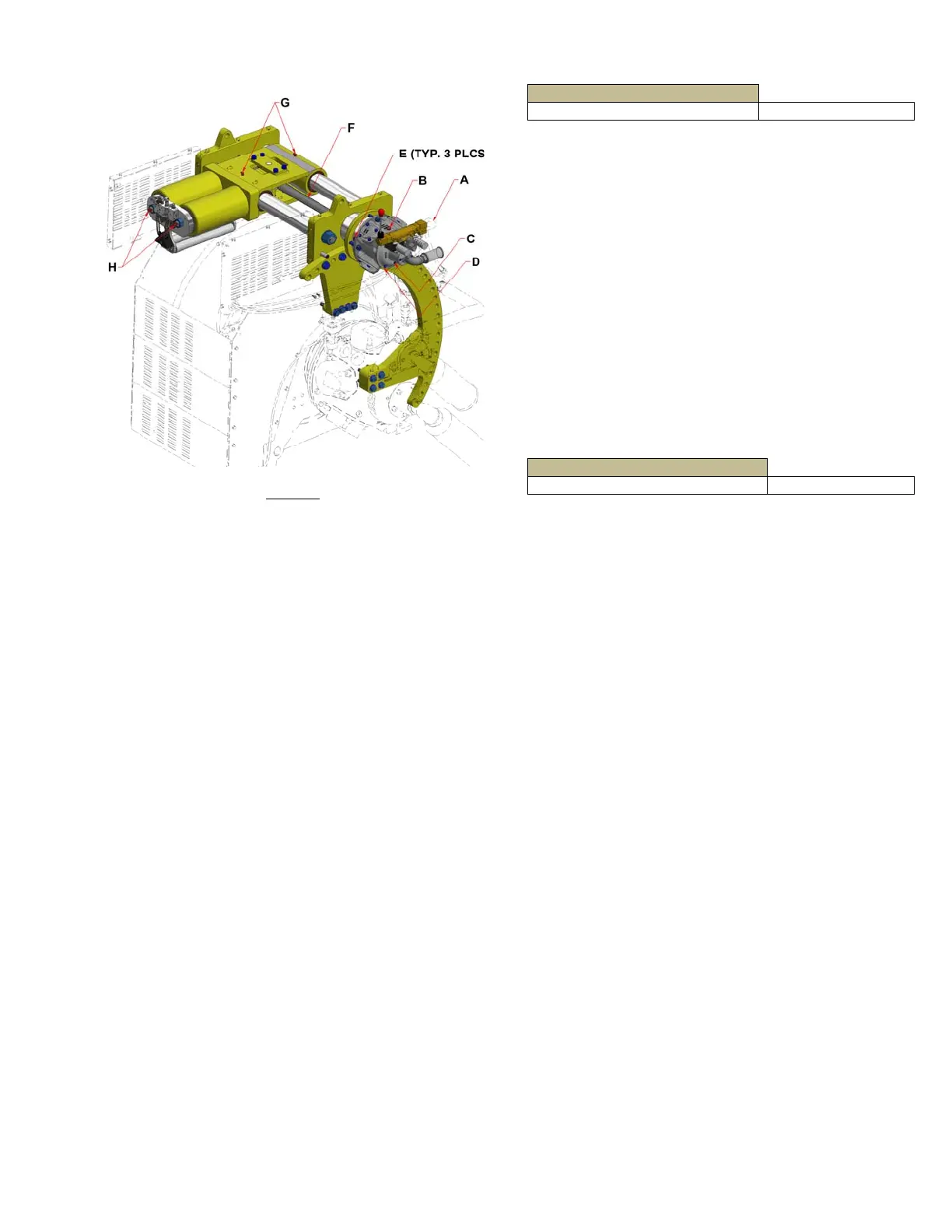

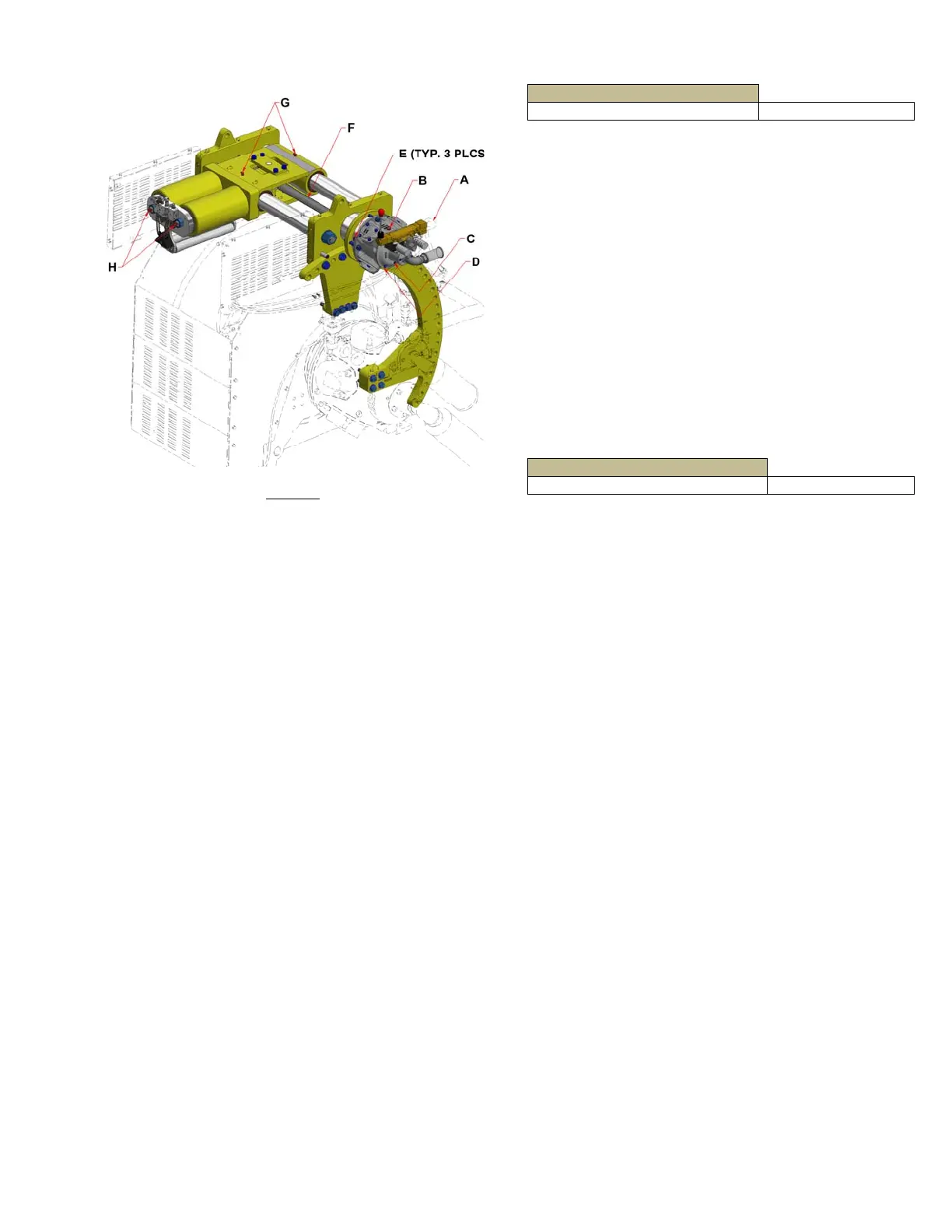

Figure10

Air Line Lubricator – (Point A) The levelwind motor is a piston

motor with a rotary valve that receives lubrication thru the air

stream via the in‐line air lubricator.The rate at which the

lubricatorinjectsoilintotheairstreamshouldbeat8to10drops

per

minute.Maintainalevelofoilinthelubricatorbowl.Usean

ISOVG100(SAE30W)oilandcheckregularly.

Motor–(PointsB/C/D)Theoillevelintheairmotorneedstobe

maintained and checked at the start of each shift.Correct

lubricationisakeyfactorin

properlymaintainingtheairmotorin

ordertoensureitslongevityandoperatingefficiency.Themotor

internalcomponentsaresplashlubricatedbytheoilinthesump.

Therefore,itisextremelyimportanttomaintaintheoillevelwith

a high quality extreme pressure, rust inhibiting, non‐detergent

motoroil.Fill/Add

oiltothe motor viathefill/vent cap(PointB)

locatedinthetopofthemotorhousing.Properoillevels can be

checkedatthelevelplug(PointC).

During normal operation moisture can collect in the motor

housing.This will be even more prevalent in cold temperature

environments where

there is a large deviation between the

operating temperature of the motor and the ambient air

temperature.This accumulated moisture should be drained

regularly (Point D) after the winch has been allowed to sit for a

period of time to allow the water to separate out from the oil.

Any

fluiddrainedoffshouldbedisposedofinanenvironmentally

safeandresponsiblemanner.

Thefollowingtablesgivetheoilcapacity.Usethesameoilasthe

primaryairmotorasdiscussedinSection5.6.

OilCapacity(approx.)

Motor 10floz.(0.3liters)

Gearbox – (Point E) The gearbox that connects the air motor to

theacmescrewisaplanetarytypeunitthatrunsinoil.Thereare

three(3)plugslocatedonthebodyofthegearbox.Dependingon

the mounting orientation of the levelwind, use the plug oriented

at the

upper most location as the fill and the plug at the lowest

most location as the drain.The plug, at the mid line of the

gearboxhousingservesasthelevelport.Removethelevelplug–

oilshouldbevisibleatthisport.Usethesamelubricantasusedin

thelevelwindairmotor.

Every 2000 hours or every 12months completely drain the oil in

the gearbox via the port on the bottom side and replenish with

freshoil.

Thefollowingtablegivestheoilcapacity:

OilCapacity(approx.)

LevelwindGearbox 12floz.(0.35liters)

ACME Screw – (Point F) The levelwind carriage is pushed and

pulled through its travel via the bronze ACME threaded nut

running on the stainless steel screw.Since, the screw thread is

open to the environment, Ram does not recommend using a

heavybearinggrease whichwouldquickly become contaminated

withdirtanddebris. Instead,routinelycleanthescrewandwitha

paint brush apply a light motor oil (SAE 30W) to the screw

threads.

This should be done on a routine basis particularly before

deployingorretrievinglongrunsofwirerope.

Guide Bars – (Point G) – The carriage slides on two hardened

guide bars with bronze bushings located in the carriage.These

bushingsreceivelubrication through two (2) grease zerks located

on the levelwind carriage.Guards will need to be removed to

accesstheselubricationpoints.

On a monthly basis, pump a quality bearing grease (8 to 10

pumps)througheachgreasezerk.Routinelypumpinggreaseinto

the bushings acts to replenish the lubricant as well as flush out

any contaminants.Depending on the amount of usage and the

environment, this process may need to be repeated during the

operationcycle.

Ram recommends using Shell Gadus V220 2 Grease.

Or other

extremepressureandanti‐wearlithiumgrease.

WireRope Rollers–(PointH)–The2wireroperollersrotateon

bronze bushings spinning on stainless steel shafts.These rollers

arelubricatedthroughtwo (2)greasezerks locatedonthetopof

the rollers.Guards will need to

be removed to access these

lubricationpoints.

Loading...

Loading...