OIM‐600056 Rev.0 8

3. Installation

The design of the mounting structure for the winch should take

intoaccounttheweightoftheunit,additionalvesselaccelerations

and angles, as well as applied line pulls.Consult a structural

engineer.

The Ram R7P is designed to be mounted with the provided bolt

pattern directly to the customer’s rigid steel structure. Ram

recommendsusingstructural grade fastenersASTMA490,orSAE

Grade8orbetter.RefertoSection3.2forInstallationTolerances

forflatnessandotherdimensionalparameters.Theprovidedbolt

pattern is given on drawing S001960 located in Section 5 of this

manual.

Avoid welding on the frame of the winch.If welding must be

done, limit it to the frame only and position the ground clamp

close to where the welding is to occur.Take every precaution to

not

arc the bearing or over‐heat shaft seals.Protect hoses from

sparks and excessive heat.Care should be taken to not allow an

electricarctopassthroughthewirerope.

Ifweldinghastobedonetothewinchframe,pleasenote thatthe

Ramwinchframeisconstructedof anAWSGroupIand/orGroup

II material.Always use a qualified weld procedure and certified

personnel.Always abide by safety procedures established and

governedby yourspecific area of

operation.Make sure the area

issafebeforebeginninganyweldingprocedures.

Prior to installation, carefully inspect the unit for any signs of

damage that may have occurred during shipping.Before

operation, verify oil levels and correct if necessary.Refer to the

Lubricationsectionofthismanualforrecommendations.

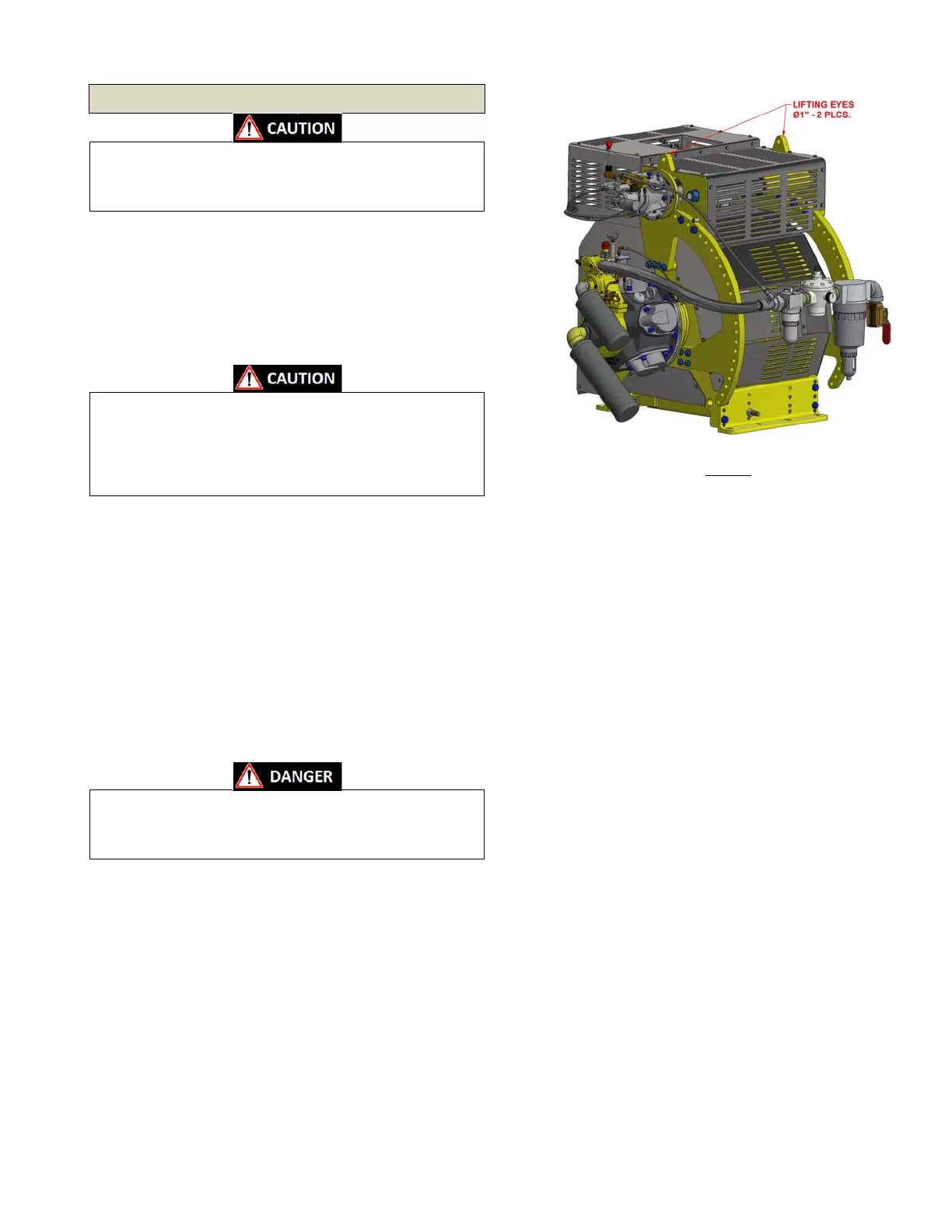

3.1. ShippingandHandling

Lifting of equipment should only be conduct ed by skilled and

properlytrainedandauthorizedpersonnel.Onlyusecertifiedan d

properlysizedriggingequipment.Keepallpersonnelclearoflifted

items.

TypicallythewinchisshippedfromtheRamfactoryonawooden

palletthatisintendedforhandlingthewinchwithaforklift.This

pallet should not be used for overhead lifting where slings are

wrappedunderthroughtheforkliftpockets.

When lifting the winch into position for

final mounting, it is

recommendedthattheprovidedliftingeyes(qty.2)onthewinch

framebeutilized(seeFigure1).

Use a 3/4 in. shackle to provide sufficient throat depth in the

shackle for lifting sling clearance.After placing the winch into

position and removing the shackles.Note: details may

vary by

model,anddrumguardconfiguration.

3.2. InstallationTolerances

Once the Winch is set into position, check the mounting surface

forflatness.Themountingsurfaceshouldbeflatandlevelwithin

0.06in. (1.5mm).If necessary, shim under each mounting bolt

hole location to ensure that the frame sits flat, level, and is

properlysupported.

Use 7/8inch (22 mm) Grade 8

or ASTM A490 or better mounting

hardware and use with lock washers, and hex nuts of similar

grade.LubricatethethreadsoftheboltswithAnti‐Seizeorsimilar

andtorqueevenlyto394ft*lbs.(534N*m).

3.3. WireRope

Theminimumrecommendedropesizeforthiswinchis7/8in.(22

mm).Whenselectingtherequirementsforthewireropeforyour

particular application it is important that you maintain a proper

safety factor as well as selecting proper wire rope construction

type,directionoflay,protectivecoating,etc.Consult

areputable

wire rope manufacturer or distributor for assistance in the

selection.

Other considerations for the wire rope are the size of turning

sheavesanddirectionoftheturnsintherope.Maintainaproper

pitch diameter to wire rope diameter ratio as bending rope too

tightlyreducesthestrength

oftheropeanddecreasestheservice

life.Back bending the rope, bending the rope in a direction

opposite of how it is wrapped on the drum should be avoided if

possible.

Figure1

Loading...

Loading...