PG13

•

39

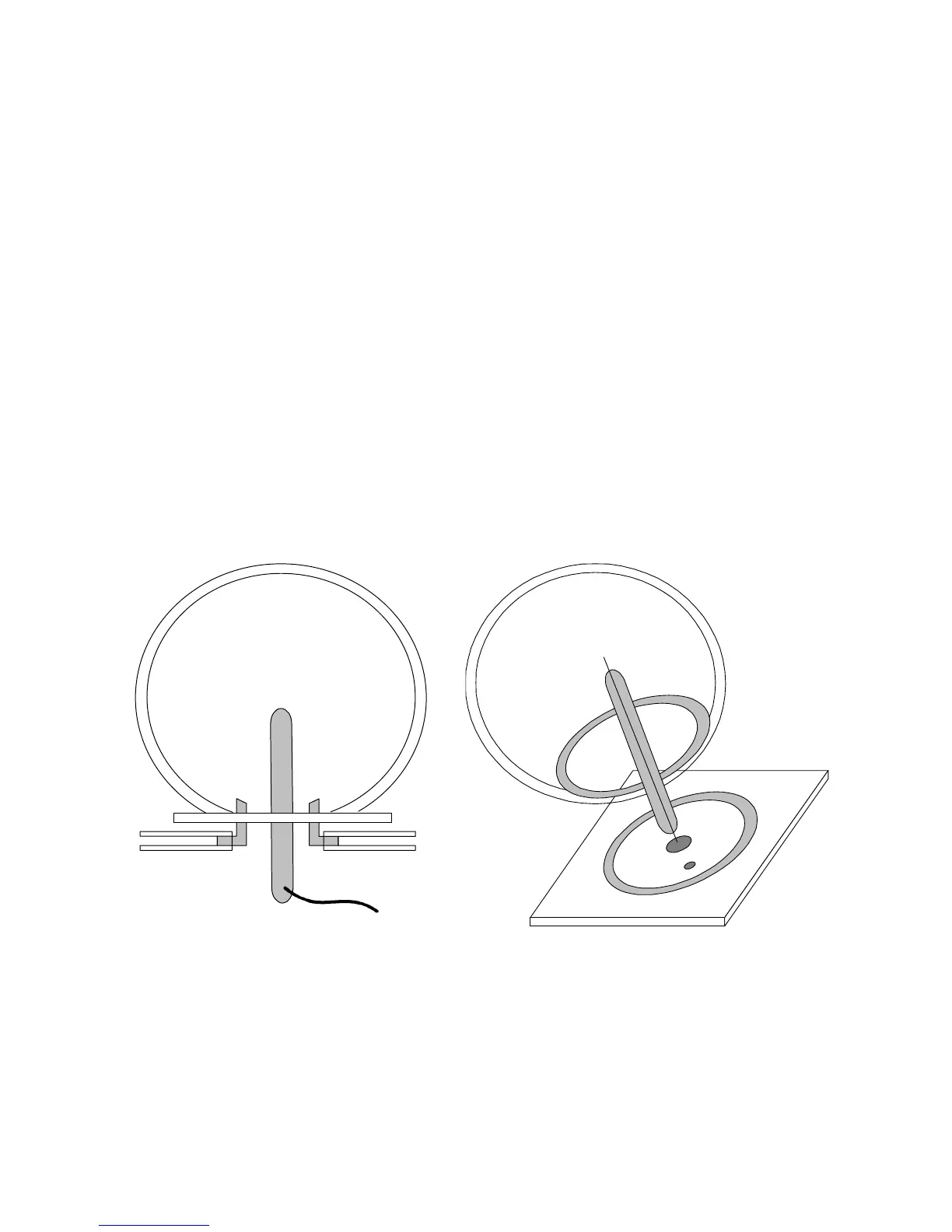

6. Drill two small holes somewhere within the dome circle on the vinyl.

This will be where you insert and remove special gases through your tube

fixtures. These MUST be sealed well. You will need to choose your hole

sizes according to the fixtures used.

7. Install the hose fixtures in the vinyl and seal them in place. Let all glue/

goop dry.

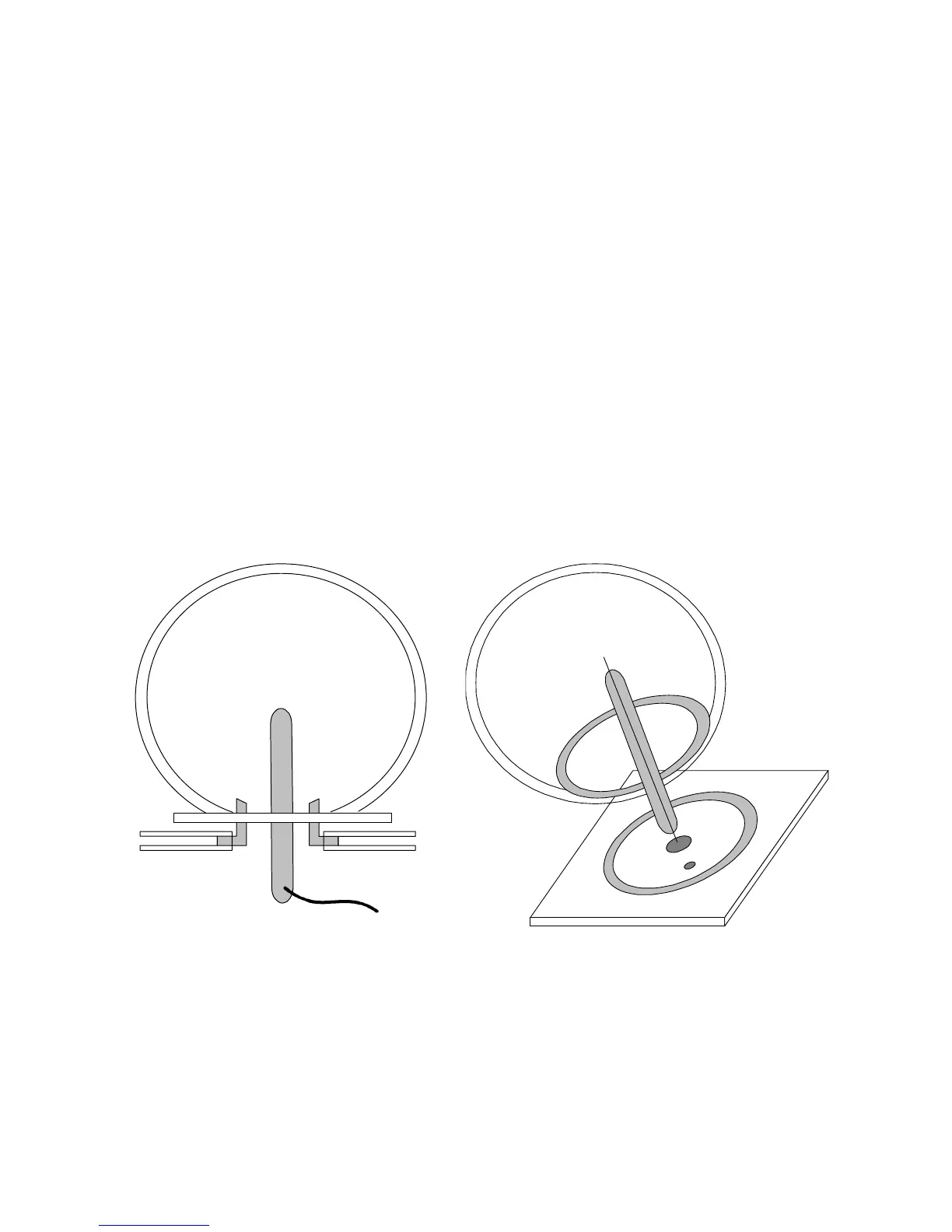

8. Lay a heavy bead of sealant into the route you carved in the vinyl.

9. Carefully push the dome on top of the caulk making sure you have

centered it well for a good seal.

10. Let the assembly dry for at least a day so the silicone will not vent too

much, and things will stay together.

11. Use a permanent marker to put alignment marks on the dome and

vinyl base. This will allow you to remove and replace the dome as needed

for experiments. Silicone sealant should not stick very well to vinyl,

allowing you to remove and replace the dome. If you make any sort of

vacuum in the dome, the pressure from outside air should form a nice tight

seal.

Maybe you can come up with some better ideas, or less expensive ways to

do this, but this will get you started. You will also need some other things like

hose clamps to act as valves, possibly a vacuum pump (a hand vacuum pump

should work), and maybe even some specialized gases. I heard a rumor that

welder’s argon will ionize easily at normal air pressure, so you may not even

need a vacuum pump!

Gas in

Gas out

HV

Loading...

Loading...