7

6. Align the riveter with the drilled hole as best as you can and insert

the rivet head into it.

7. Drive FORWARD until the mandrel is popped off of the rivet. When

you hear that the rivet is set, continue to pull the trigger for few

seconds, to be sure the mandrel comes off correctly.

8. Drive BACKWARD to release and expose the remaining rivet man-

drel. Depending on the greasing of the tool jaw pieces, the mandrel

may or may not fall out on its own.

V. Maintenance

1. Clean the components of plunger tube and re-lubricate its parts, at

least on a yearly basis.

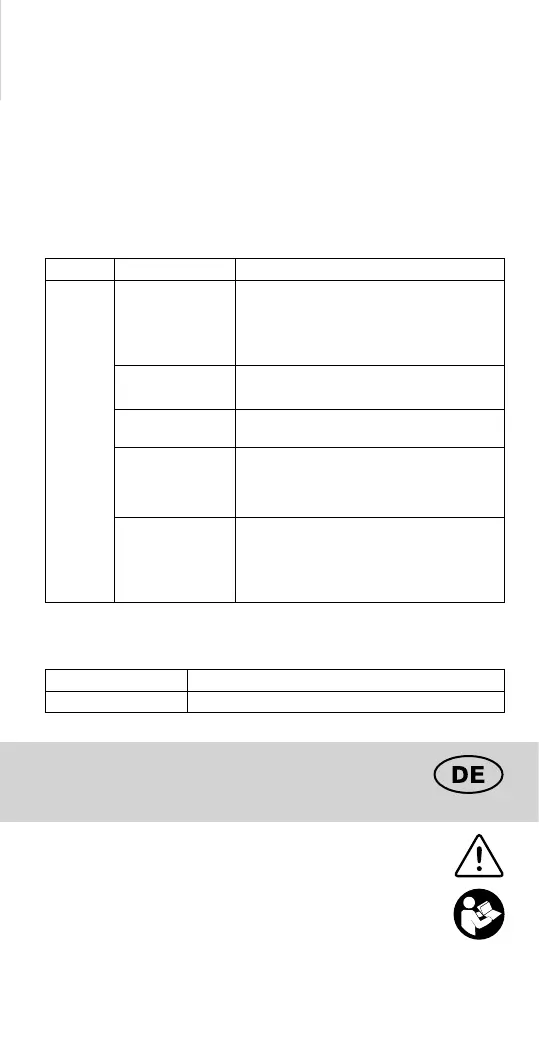

VI. Trouble-Shooting

Issue Possible causes Solutions

Spent

mandrel

jam

Assembly grease

The mandrel of a spent rivet might not fall out

from grease even if correctly released. With

plunger tube in full forward position, insert

rivet several times to clear grease or blow/

clean out jaws.

Loose nosepiece

Tighten the nosepiece with included

wrench or equivalent.

Loose front tube

Tighten front tube fi rst and then tighten lock-

ing ring with included wrench or equivalent.

Spent mandrel

is loose but not

exposed enough to

grab with hands

Try to set your rivet not against the nosepiece,

leaving a 1/16-1/8” (1- 3mm) gap between

the rivet and the tool to leave the mandrel

more exposed when returned forward.

Persistent jamming

Re-tighten the nosepiece, front tube and

locking ring. Then, turn the hex shank

anti-clockwise until an audible sound comes

from the tool and shake to remove the

mandrel.

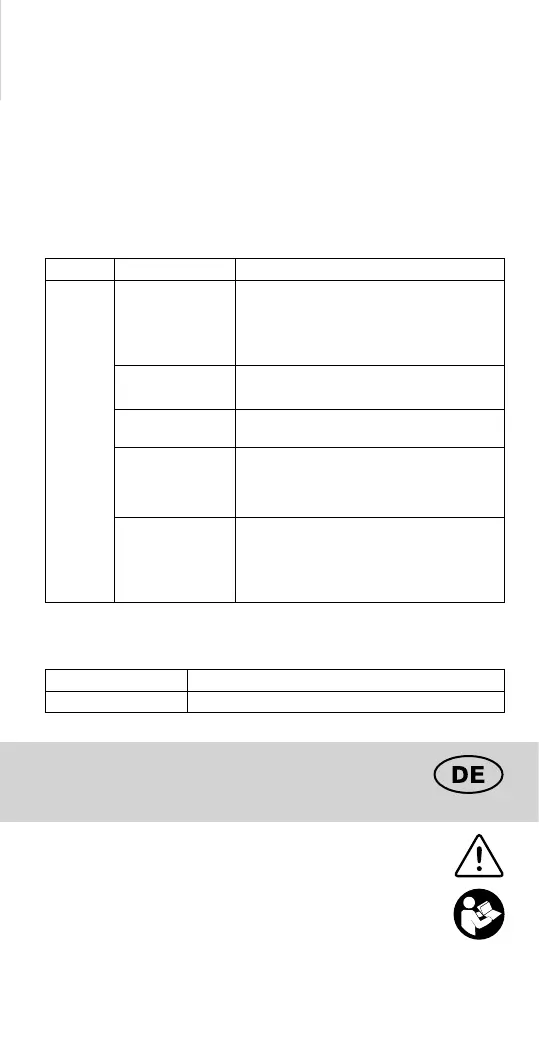

VII. Spare parts list

Follow local regulations when disposing of the tool.

Art. No Description

5001578 Jaws, Main Spring, 3x Multi nozzle

Lesen Sie die Bedienungsanleitung vor Verwendung

sorgfältig durch.

Dieser Nietvorsatz ist mit unserem Multi™ Mundstück ausges-

tattet, mit dem sich Niete Ø 3,2 mm - Ø 4 mm - Ø 4,8 mm

setzen lassen.

I. Anforderungen an das Antriebswerkzeug

1. Werkzeug muss mit einstellbarer Drehmomenteinstel-

lung ausgestattet sein. Akku-Bohrmaschine oder Akkuschrauber,

mit dem Sie zwischen mehreren Drehmomentpositionen wählen

MULTI NIETVORSATZ FÜR

AKKUSCHRAUBER : RP150 MULTI™

Betriebsanleitung- Übersetzung der ursprünglichen

Loading...

Loading...