PR

ESS

URE

TRANSDUCER

INSERTED

IN

CYLINDER CHAMBER

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii RCA WO-33A Cathode-Ray Oscilloscope·

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiijiiiiii,

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

VH~RATION

PICKUP

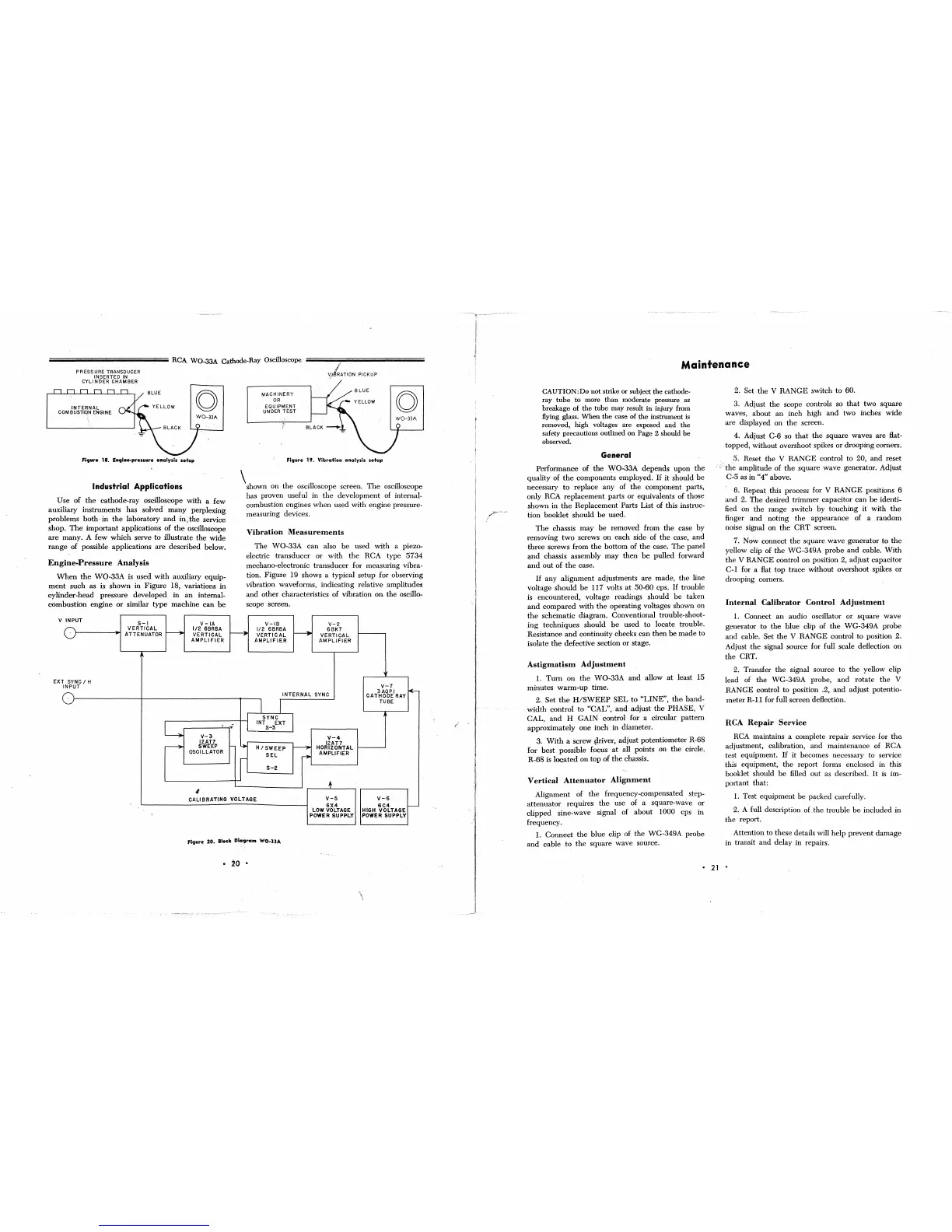

Figure 18. ElIglne-pressure analysis

setup

Industrial Applications

Use

of

the

cathode-ray

oscilloscope

with

a

few

auxiliary instruments has solved

many

perplexing

problems

both·

in

the

laboratory

and

iu;the

service

shop.

The

important

applications of

the

oscilloscope

are

many.

A

few

which

serve

to

illustrate

the

wide

range

of possible applications

are

described

below.

Engine-Pressure

Analysis

When

the

WO-33A

is

used

with

auxiliary

equip-

ment

such

as is

shown

in

Figure

18, variations

in

cylinder-head

pressure

developed in

an

intemal-

combustion

engine

or

similar

type

machine

can

be

V INPUT

S-\

V

-\A

-

VERTICAL

~

1/2

6BR8A

ATTENUATOR

VERTICAL

AMPLIFiER

I'

EXT

SYNC / H

INPUT

L

•

V-3

12AT7

~

SWEEP

OSCILLATOR

-I

MACHINERY

OR

EQUIPMENT

UNDER

TEST

"

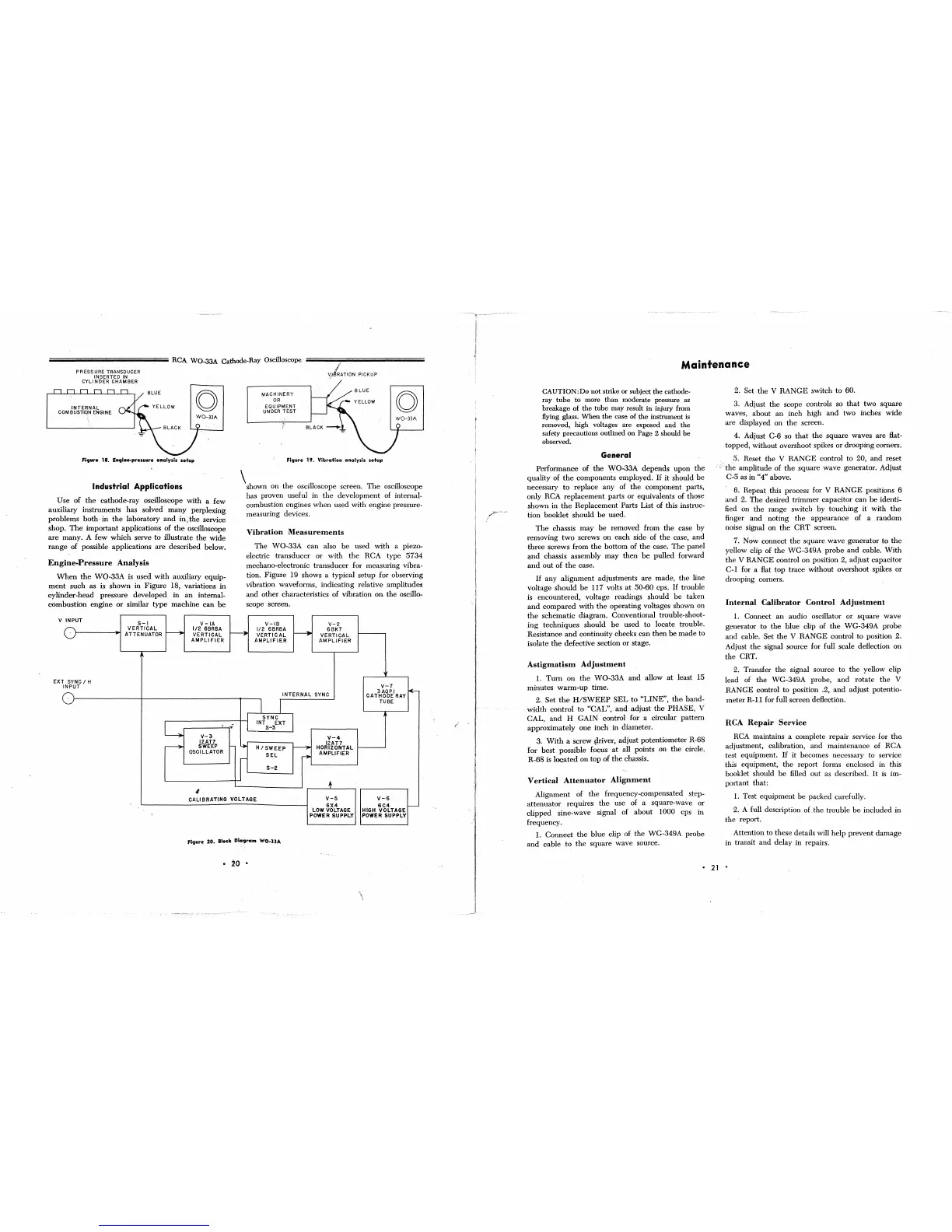

Figure 19. Vibration analysis

setup

\shown

on

the

oscilloscope screen.

The

oscillosmpe

has proven useful in

the

development

of internal-

combustion engines

when

used

with engine pressure-

measuring devices.

Vibration

Measurements

The

WO-33A

can

also

be

used

with

a piezo-

electric

transducer

or

with

the

RCA type

5734

mechano-electronic

transducer

for measuring vibra-

tion.

Figure

19 shows a typical

setup

for observing

vibration waveforms,

indicating

relative amplitudes

and

other

characteristics

of

vibration

on

the

oscillo-

scope screen.

V-IB

V-2

~

1/2

6BR8A

~

6BK7

VERTICAL

VERTICAL

AMPLIFIER

AMPLIFIER

Ii

V-7

3AQPI

~

INTERNAL

SYNC

CATHODE

RAY

j

I

TUBE

SYNC

J

-

INT

EXT

S-3

Y-4

!-

~

H /

SWEEP

~

12AT7

HORIZONTAL

SEL

r-

AMPLIFIER

r

S-2

+

CALIBRATING

VOLTAGE

V-5

Y-6

6X4

6C4

I--

LOW VOLTAGE

HIGH

VOLTAGE

,

POWER SUPPLY POWER SUPPLY

Figure 20.

Block

Diagram WO-33A

•

20

•

Maintenance

CAUTION :Do not strike or subject the cathode-

ray tube to more than moderate pressure

as

breakage

of

the tube may result in injury from

Hying

glass. When the case of the instrument is

removed, high voltages are exposed and the

safety precautions outlined on

Page 2 should be

observed.

General

Performance

of

the

WO-33A

depends

upon

the

quality of

the

components employed.

If

it

should

be

necessary

to

replace

any

of

the

component

parts,

only

RCA

replacement

parts

or

equivalents of those

shown

in

the

Replacement·

Farts

List

of this instruc-

tion booklet

should

be

used.

The

chassis

may

be

removed from

the

case

by

removing

two

screws

on

each

side of

the

case,

and

three

screws from

the

bottom

of

the

case.

The

panel

~nd

chassis assembly

may

then

be

pulled forward

and

out

of

the

case.

If

any

alignment

adjustments

are

made,

the

line

voltage

should

be

117 volts

at

50-60 cps.

If

trouble

is

encountered,

voltage readings should

be

taken

and

compared

with

the

operating

voltages shown on

the

schematic

diagram. Conventional trouble-shoot-

ing

techniques

should

be

used

to

locate trouble.

Resistance

and

continuity checks

can

then

be

made

to

isolate

the

defective section

or

stage.

Astigmatism

Adjustment

1.

Turn

on

the

WO-33A

and

allow

at

least 15

minutes

warm-up

time.

2.

Set

the

H/SWEEP

SEL

to

"LINE",

the

band-

width

control

to

"CAL",

and

adjust

the

PHASE,

V

CAL,

and

H

GAIN·

control· for a circular

pattern

approximately

one

inch

in diameter.

3.

With

a screw -priver,

adjust

potentiometer R-68

for

best

possible focus

at

all points on

the

circle.

R-68 is

located

on

top

of

the

chflssis.

Vertical

Attenuator

Alignment

Alignment

of

the

frequency-compensated.

step-

attenuator

requires

the

use of a square-wave or

clipped

sine-wave signal of

about

1000 cps in

frequency.

1.

Connect

the

blue

clip of

the

WG-349A

probe

and

cable

to

the

square

wave

source.

2.

Set

the

V

RANGE

switch

to

60.

3. Adjust

the

scope controls so

that

two

square

waves,

about

an

inch high

and

two

inches

wide

are

displayed

on

the

screen.

4. Adjust

C-6 so

that

the

square

waves are Hat-

topped, without overshoot spikes

or

drooping corners.

5. Reset

the

V

RANGE

control to 20,

and

reset

'.r

the

amplitude of

the

square

wave

generator. Adjust

C-5 as in

"4" above.

6. Repeat this process for

V

RANGE

positions 6

and

2.

The

desired

trimmer

capacitor

can

be

identi-

fied on

the

range

switch

by

touching

it

with

the

finger

and

noting

the

appearance

of a

random

noise signal

on

the

CRT

screen.

7. Now connect

the

square

wave

generator

to

the

yellow clip of

the

WG-349A

probe

and

cable.

With

the

V RANGE control

on

position 2, adjust capacitor

C-l

for a

Hat

top

trace

without

overshoot spikes

or

drooping corners.

Internal

Calibrator

Control

Adjustment

1.

Connect

an

audio oscillator

or

square

wave

generator

to

the

blue

clip of

the

WG-349A

probe

and

cable. Set

the

V

RANGE

control

to

position 2.

Adjust

the

signal source for full scale deHection

on

the

CRT.

2. Transfer

the

signal source to

the

yellow clip

lead of

the

WG-349A probe,

and

rotate

the

V

RANGE

control

to

position .2,

and

adjust

potentio-

meter

R-l1

for full screen deHection.

RCA

Repair

Service

RCA maintains a complete

repair

service for

the

adjustment, calibration,

and

maintenance

of RCA

test equipment.

If

it

becomes necessary to service

this equipment,

the

report forms enclosed in this

booklet should

be

filled

out

as described.

It

is

im-

portant

that:

1. Test

equipment

be

packed

carefully.

2. A full description

oLthe

trouble

be

included

in

the report.

Attention to these details will

help

prevent

damage

in transit

and

delay in repairs.

•

21

•

Loading...

Loading...