REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Inspection and Maintenance

Evaporator / Coil Cleaning.

Testing

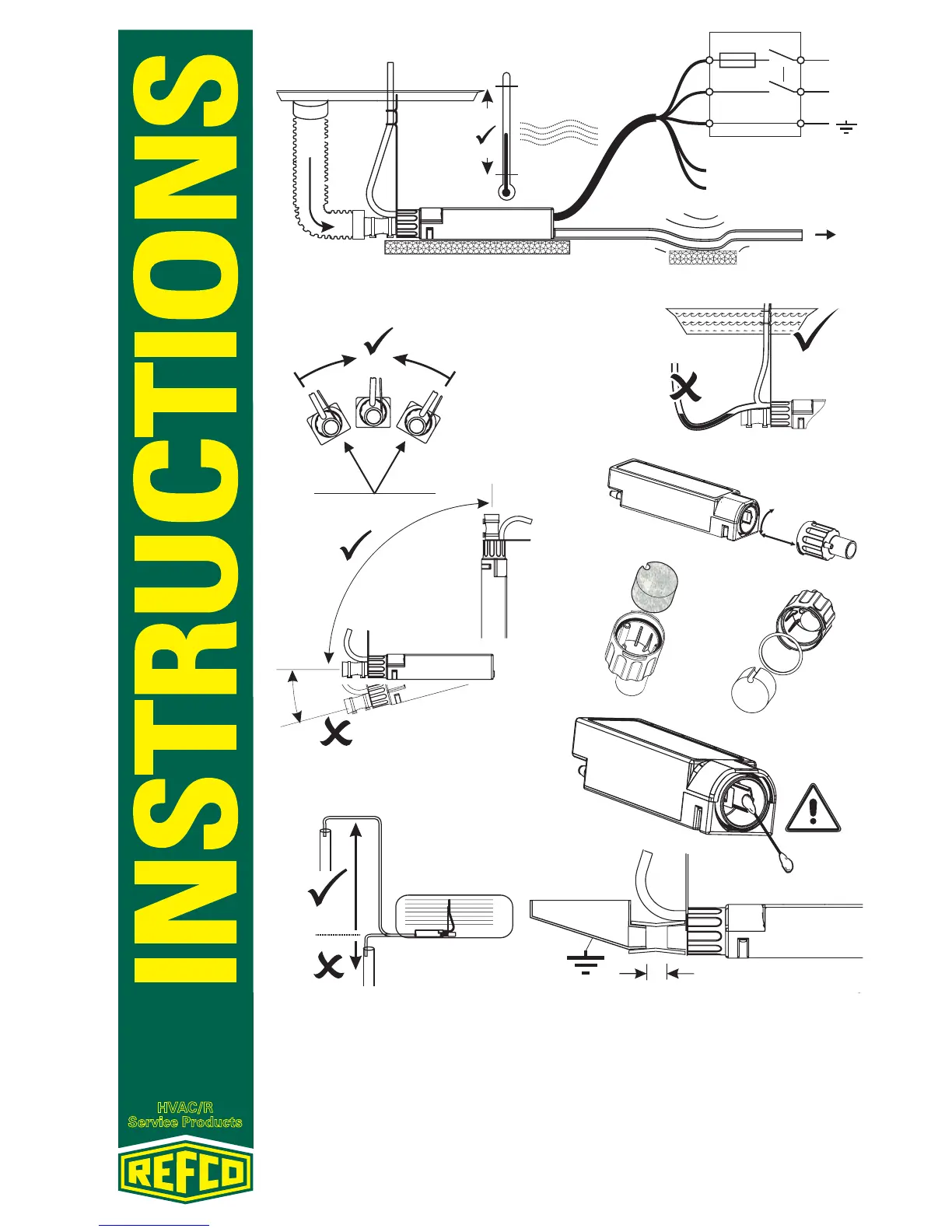

Inspect the filter for sediment and debris.

When handling pump during inspection and

maintenance, k

If cleaning is required, disconnect the filter

housing by rotating 80° Counter clockwise and

carefully separate (fig.9).

Inspect the Inlet Tube for dirt and blockages

and clean if required.

carefully pour clean water

eep Pump Assembly reasonably

upright and level to prevent any water spills

from entering the pump.

In some installations it may be possible to

service the pump while still attached to the

equipment. If necessary support the Pump

Assembly to prevent excessive strain on cables

and connections.

Using a small tool carefully lift the filter out of its

location and rinse under a tap with clean water.

If the O ring is disturbed, clean O ring and

mating surfaces and re-seat (fig.10).

Inside of the Sensor chamber check for debris

between the sensor plates . Clean gently with

a soft cloth or Q-tip (fig.11).

Clean the sealing surface and re-assemble the

Filter chamber onto the pump

Inspect the discharge tube for blockages and

kinks.

Inspect the Breather tube for positioning and

obstructions.

When using evaporator cleaning agents,

drain discharged liquid into a separate

container and flush with clean water. Do not

allow cleaning agents and dirt to drain into

Pump.

On new installations, flush installation debris

through condensate system into a bucket,

before connecting the pump. If possible

via the condensate

collection tray to check also the water drain

route.

Use a wash bottle if possible as these are more

controllable.

The pump should begin to pump until all, but

approximately 12mm / 1/2" of water is left

remaining.

Do not use detergents in servicing this product.

Do not scratch

sensitive surfaces.

Installation

Location

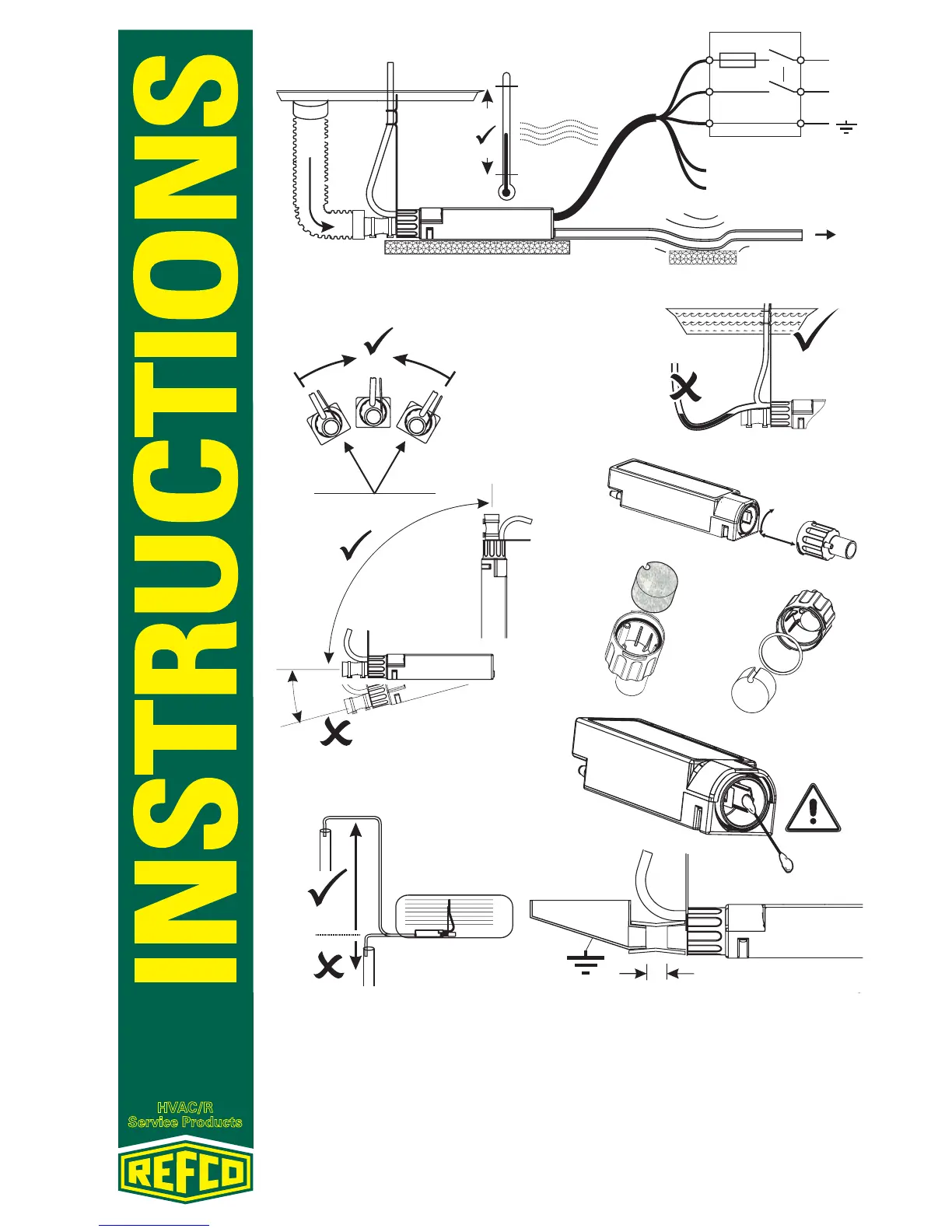

This Pump is not submersible. Select a suitable location for the

pump within the equipment which is level (fig. 4 & 5) and not likely

to be disturbed in general use. Ensure the drain hose slopes

down directly to the pump without drooping and kinking (fig. 3).

Separate the Pump and Discharge Tube from panels and surfaces

with insulating foam rubber to further reduce noise transmission.

If

connecting directly to Earthed/ Grounded Metal Tray or pipes,

allow 15mm/ 5/8" distance between parts (fig.12).

Run discharge tubing to a suitable drain where it is unlikely to

freeze during operation. The highest point of the run must be less

than 49ft/ 15m above the Pump and not more than 0.3m(1ft)

below to avoid siphoning (fig. 7). Maximum tube length is 330ft/

100m. Take care not to pinch or kink the tubing. Secure or support

the discharge tube to reduce noise.

Push the rubber Inlet Connector onto the drain hose (fig. 3) or

collection tray stub. Secure with the cable ties provided.

Bend into position the breather support wire so tube end is above

collection tray if possible (fig.8).

WARNING! SWITCH OFF ALL SUPPLIES AT THE FUSE BOX

BEFORE MAKING CONNECTIONS TO THIS PUMP.

The installation must provide a suitable means for electrical

disconnection (fig.3).

Fuse Protection Required: Europe 5 Amp max.

European Cable: 0.75mm²

USA. Factory fitted cable is 18 AWG for equipment internal wiring

only.

Refer to National and Local Electrical Codes for fusing and

disconnection requirements.

The alarm relay is energised to make continuity during

normal operating conditions (break on fault).

Piping

Wiring

Alarm Relay

This pump requires an Earth/ Ground connection.

EUROPEAN

USA

Cable Colour Coding

BROWN L

LIVE PHASE

BLUE N

NEUTRAL

GREEN/YELLOW E EARTH

BLACK ALARM

RELAY

GREY ALARM

RELAY

Cable Colour Coding

BLACK L1

LIVE PHASE

WHITE L2

NEUTRAL

GREEN GROUND

ORANGE ALARM

RELAY

RED ALARM

RELAY

(PHASE 2, 220V

SYSTEM)

CAUTION: DISCONNECT ALL POWER SUPPLY BEFORE PERFORMING ANY

SERVICING OR MAINTENANCE. ONLY COMPETENT PERSONS SHOULD ATTEMPT TO

SERVICE THIS PRODUCT.

30°

30°

fig. 4

fig. 5

15M/ 49ft max

fig. 7

fig. 8

fig. 9

fig. 10

fig. 11

LIT-2500

fig. 12

15mm/ 5/8"

p2

p3

50°C

122°F

0 °C

32°F

SUPPLY

VOLTAGE

N

L

5A

Alarm or

Thermostat Circuit.

fig. 3

Inspection and Maintenance

Evaporator / Coil Cleaning.

Testing

Inspect the filter for sediment and debris.

When handling pump during inspection and

maintenance, k

If cleaning is required, disconnect the filter

housing by rotating 80° Counter clockwise and

carefully separate (fig.9).

Inspect the Inlet Tube for dirt and blockages

and clean if required.

carefully pour clean water

eep Pump Assembly reasonably

upright and level to prevent any water spills

from entering the pump.

In some installations it may be possible to

service the pump while still attached to the

equipment. If necessary support the Pump

Assembly to prevent excessive strain on cables

and connections.

Using a small tool carefully lift the filter out of its

location and rinse under a tap with clean water.

If the O ring is disturbed, clean O ring and

mating surfaces and re-seat (fig.10).

Inside of the Sensor chamber check for debris

between the sensor plates . Clean gently with

a soft cloth or Q-tip (fig.11).

Clean the sealing surface and re-assemble the

Filter chamber onto the pump

Inspect the discharge tube for blockages and

kinks.

Inspect the Breather tube for positioning and

obstructions.

When using evaporator cleaning agents,

drain discharged liquid into a separate

container and flush with clean water. Do not

allow cleaning agents and dirt to drain into

Pump.

On new installations, flush installation debris

through condensate system into a bucket,

before connecting the pump. If possible

via the condensate

collection tray to check also the water drain

route.

Use a wash bottle if possible as these are more

controllable.

The pump should begin to pump until all, but

approximately 12mm / 1/2" of water is left

remaining.

Do not use detergents in servicing this product.

Do not scratch

sensitive surfaces.

Installation

Location

This Pump is not submersible. Select a suitable location for the

pump within the equipment which is level (fig. 4 & 5) and not likely

to be disturbed in general use. Ensure the drain hose slopes

down directly to the pump without drooping and kinking (fig. 3).

Separate the Pump and Discharge Tube from panels and surfaces

with insulating foam rubber to further reduce noise transmission.

If

connecting directly to Earthed/ Grounded Metal Tray or pipes,

allow 15mm/ 5/8" distance between parts (fig.12).

Run discharge tubing to a suitable drain where it is unlikely to

freeze during operation. The highest point of the run must be less

than 49ft/ 15m above the Pump and not more than 0.3m(1ft)

below to avoid siphoning (fig. 7). Maximum tube length is 330ft/

100m. Take care not to pinch or kink the tubing. Secure or support

the discharge tube to reduce noise.

Push the rubber Inlet Connector onto the drain hose (fig. 3) or

collection tray stub. Secure with the cable ties provided.

Bend into position the breather support wire so tube end is above

collection tray if possible (fig.8).

WARNING! SWITCH OFF ALL SUPPLIES AT THE FUSE BOX

BEFORE MAKING CONNECTIONS TO THIS PUMP.

The installation must provide a suitable means for electrical

disconnection (fig.3).

Fuse Protection Required: Europe 5 Amp max.

European Cable: 0.75mm²

USA. Factory fitted cable is 18 AWG for equipment internal wiring

only.

Refer to National and Local Electrical Codes for fusing and

disconnection requirements.

The alarm relay is energised to make continuity during

normal operating conditions (break on fault).

Piping

Wiring

Alarm Relay

This pump requires an Earth/ Ground connection.

EUROPEAN

USA

Cable Colour Coding

BROWN L

LIVE PHASE

BLUE N

NEUTRAL

GREEN/YELLOW E EARTH

BLACK ALARM

RELAY

GREY ALARM

RELAY

Cable Colour Coding

BLACK L1

LIVE PHASE

WHITE L2

NEUTRAL

GREEN GROUND

ORANGE ALARM

RELAY

RED ALARM

RELAY

(PHASE 2, 220V

SYSTEM)

CAUTION: DISCONNECT ALL POWER SUPPLY BEFORE PERFORMING ANY

SERVICING OR MAINTENANCE. ONLY COMPETENT PERSONS SHOULD ATTEMPT TO

SERVICE THIS PRODUCT.

30°

30°

fig. 4

fig. 5

15M/ 49ft max

fig. 7

fig. 8

fig. 9

fig. 10

fig. 11

LIT-2500

fig. 12

15mm/ 5/8"

p2

p3

50°C

122°F

0 °C

32°F

SUPPLY

VOLTAGE

N

L

5A

Alarm or

Thermostat Circuit.

fig. 3

Inspection and Maintenance

Evaporator / Coil Cleaning.

Testing

Inspect the filter for sediment and debris.

When handling pump during inspection and

maintenance, k

If cleaning is required, disconnect the filter

housing by rotating 80° Counter clockwise and

carefully separate (fig.9).

Inspect the Inlet Tube for dirt and blockages

and clean if required.

carefully pour clean water

eep Pump Assembly reasonably

upright and level to prevent any water spills

from entering the pump.

In some installations it may be possible to

service the pump while still attached to the

equipment. If necessary support the Pump

Assembly to prevent excessive strain on cables

and connections.

Using a small tool carefully lift the filter out of its

location and rinse under a tap with clean water.

If the O ring is disturbed, clean O ring and

mating surfaces and re-seat (fig.10).

Inside of the Sensor chamber check for debris

between the sensor plates . Clean gently with

a soft cloth or Q-tip (fig.11).

Clean the sealing surface and re-assemble the

Filter chamber onto the pump

Inspect the discharge tube for blockages and

kinks.

Inspect the Breather tube for positioning and

obstructions.

When using evaporator cleaning agents,

drain discharged liquid into a separate

container and flush with clean water. Do not

allow cleaning agents and dirt to drain into

Pump.

On new installations, flush installation debris

through condensate system into a bucket,

before connecting the pump. If possible

via the condensate

collection tray to check also the water drain

route.

Use a wash bottle if possible as these are more

controllable.

The pump should begin to pump until all, but

approximately 12mm / 1/2" of water is left

remaining.

Do not use detergents in servicing this product.

Do not scratch

sensitive surfaces.

Installation

Location

This Pump is not submersible. Select a suitable location for the

pump within the equipment which is level (fig. 4 & 5) and not likely

to be disturbed in general use. Ensure the drain hose slopes

down directly to the pump without drooping and kinking (fig. 3).

Separate the Pump and Discharge Tube from panels and surfaces

with insulating foam rubber to further reduce noise transmission.

If

connecting directly to Earthed/ Grounded Metal Tray or pipes,

allow 15mm/ 5/8" distance between parts (fig.12).

Run discharge tubing to a suitable drain where it is unlikely to

freeze during operation. The highest point of the run must be less

than 49ft/ 15m above the Pump and not more than 0.3m(1ft)

below to avoid siphoning (fig. 7). Maximum tube length is 330ft/

100m. Take care not to pinch or kink the tubing. Secure or support

the discharge tube to reduce noise.

Push the rubber Inlet Connector onto the drain hose (fig. 3) or

collection tray stub. Secure with the cable ties provided.

Bend into position the breather support wire so tube end is above

collection tray if possible (fig.8).

WARNING! SWITCH OFF ALL SUPPLIES AT THE FUSE BOX

BEFORE MAKING CONNECTIONS TO THIS PUMP.

The installation must provide a suitable means for electrical

disconnection (fig.3).

Fuse Protection Required: Europe 5 Amp max.

European Cable: 0.75mm²

USA. Factory fitted cable is 18 AWG for equipment internal wiring

only.

Refer to National and Local Electrical Codes for fusing and

disconnection requirements.

The alarm relay is energised to make continuity during

normal operating conditions (break on fault).

Piping

Wiring

Alarm Relay

This pump requires an Earth/ Ground connection.

EUROPEAN

USA

Cable Colour Coding

BROWN L

LIVE PHASE

BLUE N

NEUTRAL

GREEN/YELLOW E EARTH

BLACK ALARM

RELAY

GREY ALARM

RELAY

Cable Colour Coding

BLACK L1

LIVE PHASE

WHITE L2

NEUTRAL

GREEN GROUND

ORANGE ALARM

RELAY

RED ALARM

RELAY

(PHASE 2, 220V

SYSTEM)

CAUTION: DISCONNECT ALL POWER SUPPLY BEFORE PERFORMING ANY

SERVICING OR MAINTENANCE. ONLY COMPETENT PERSONS SHOULD ATTEMPT TO

SERVICE THIS PRODUCT.

30°

30°

fig. 4

fig. 5

15M/ 49ft max

fig. 7

fig. 8

fig. 9

fig. 10

fig. 11

LIT-2500

fig. 12

15mm/ 5/8"

p2

p3

50°C

122°F

0 °C

32°F

SUPPLY

VOLTAGE

N

L

5A

Alarm or

Thermostat Circuit.

fig. 3

Loading...

Loading...